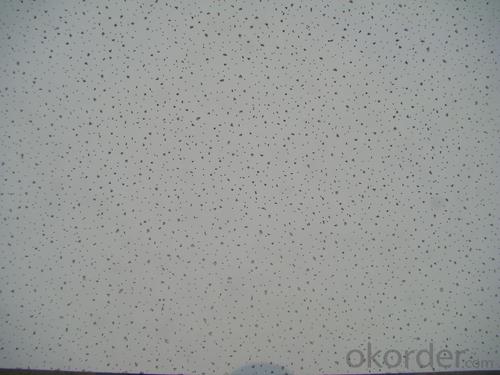

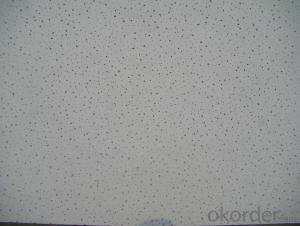

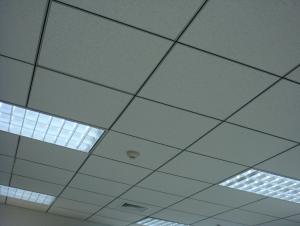

Mineral Fiber Ceiling Tiles Price - Acoustic Mineral Fiber Ceiling MA01

- Loading Port:

- Xingang China

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 1×40HQ m²

- Supply Capability:

- 20000 m² per day m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Standard Size: 595mm*595mm, 605mm*605mm

Standard Thickness: 8, 9, 10, 12, 14, 15mm

Edge Detail: Square Edge, Tegular Edge (≥12mm)

Technical Data of Acoustic Mineral Fiber Ceiling:

Density: 260-320kgs/m3

NRC: ≥0.50

Fire resistance: Class B1 (standard GB 8624-1997)

Moisture rate (%): ≤3.5 (40℃,70%RH)

Light reflect: 0.70-0.80

Sagging resistant properties: ≤0.35mm

Humidity Resistance: ≥85%

Main advantages of Acoustic Mineral Fiber Ceiling:

Wonderful sound-absorption

High humidity resistance properties

Excellent light reflectance

Environment-friendly

No content of asbestos

Zero release of CH2O

Economical Choice

Standard Thickness: 8, 9, 10, 12, 14, 15mm

Edge Detail: Square Edge, Tegular Edge (≥12mm)

Technical Data of Acoustic Mineral Fiber Ceiling:

Density: 260-320kgs/m3

NRC: ≥0.50

Fire resistance: Class B1 (standard GB 8624-1997)

Moisture rate (%): ≤3.5 (40℃,70%RH)

Light reflect: 0.70-0.80

Sagging resistant properties: ≤0.35mm

Humidity Resistance: ≥85%

Main advantages of Acoustic Mineral Fiber Ceiling:

Wonderful sound-absorption

High humidity resistance properties

Excellent light reflectance

Environment-friendly

No content of asbestos

Zero release of CH2O

Economical Choice

- Q: Car bumper decorative plate crashed, the insurance company can be that there is a rust exemption

- Bumper decoration if the original car should be to the deductible, if the post-decoration should not be done

- Q: Roewe 750 right rear door inside the decorative plate how to open

- Hello, the first screw in the Alice

- Q: for example im doing a science fair project and the expirement involves a surface of a book a plate and and the materials that complete the experiment are a loud clicking clock and two paper towl tubes and the sound should go through the tube and bounce off the book (plate) and go through the second tube.

- Smooth surfaces reflect sound better than rough surfaces. To show this, replace the book with felt or cotton balls.

- Q: Car FRP decorative board spent on how to remove

- The surface does not require high parts of the perforation, and other strong paste method.

- Q: Restaurant wall decoration board generally use what material

- Each material has advantages and disadvantages, the specific conditions can be selected according to actual conditions.

- Q: What is the role of ceiling decoration

- PVC ceiling PVC ceiling is made of polyvinyl chloride as raw materials, extruded into a frame and then made of glass and made. It has a light, wear-resistant, anti-aging, heat insulation sound insulation, moisture-proof, anti-moth and fire and so on. Mainly applicable to the kitchen, bathroom. PVC material should be purchased when the equipment conditions are good, the quality of the manufacturers to ensure that the product.

- Q: Ordinary wood finishes decorative plate surface brushing after the fire can be used as B1 grade decorative materials use? B1 level of decorative materials testing and evaluation standards?

- Normally speaking of all wood are not required (except for special materials), fire will not agree

- Q: Transparency and acrylic panels are almost decorative boards but the plates are lighter than acrylic and can you use slices with plane trims?

- Acrylic board is commonly known as plexiglass plate (PMMA)

- Q: Audi q3 tires decorative panels how to disassemble

- You have a professional tool behind you

- Q: Old paragraph Han Lanta front cover stone decoration board

- Only the installation of the decorative cover is not in place and the control station gap is too large, hoping to help you, hope to adopt

Send your message to us

Mineral Fiber Ceiling Tiles Price - Acoustic Mineral Fiber Ceiling MA01

- Loading Port:

- Xingang China

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 1×40HQ m²

- Supply Capability:

- 20000 m² per day m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords