Packaging & Delivery

Packing Details:OEM available,Packaged with a steel bottle,15 bottles in one carton.

Delivery Detail:10days after deposit.

Specifications

1.fireproof and soundproof Pu foam

2.biggest manufacturer

3.strong bonding & big bubble

4.ISO9001, ISO14001, CE

750ml High Quality Pu Foam For Construction

one part pu foam

Promotion ON at current!

Fixing and adhesion

Filling slot and Sealing

CFC-free

Good quality and price

Detailed Product Description

1.With 12 years' experience and cetification of ISO 9001&CE

2.one-component PU foam

3.Noise-resistant heat-insulation

One-component A1 grade Polyurethane Foam / PU foam

Pu foam is a single-component, moisture-curing and self-expanding pu foam

Properties

· High yield & stability and adequate pressure at low temperatures.

· Versatile and easy to use features

· Excellent adhesion on most materials.

· Very good filling capacity.

· High thermal&acoustical insulation value.

· Resistant to moisture, heat, water and many chemicals.

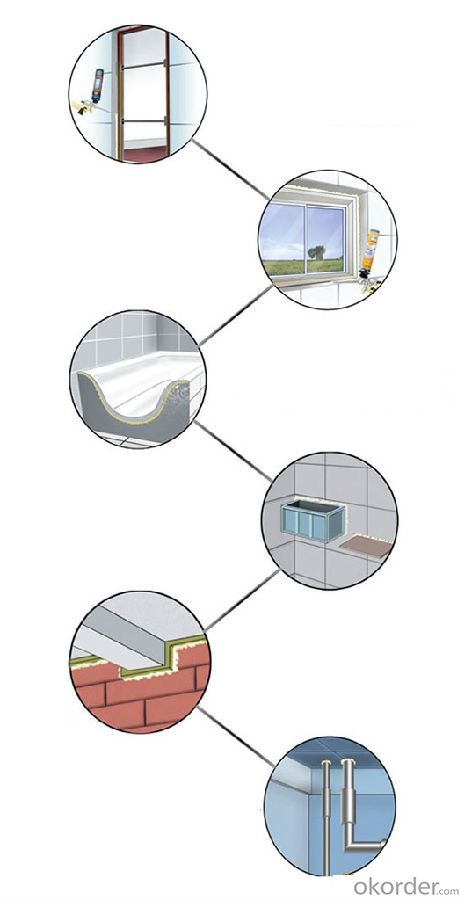

Applications

Mounting and insulating of door and window frames. Filling and sealing of gaps, joints and cavities.

Filling of penetrations in walls. Improving thermal isolation in cooling systems.

Specification

Product Name: | PU foam, PU adhesive, PU sealant, PU insulation |

Material: | Polyurethane |

Size: | 750ml |

Packing: | 15 cans per carton |

Storage Life: | 12 months when stored at 20°C |

Item | Index |

Color | Milk-white |

Surface drying time | 9-13min |

Completely cure time | 3-4h |

viscosity | suitable |

Foam Multiple | ≥standard value-10 |

Density | 14-30kg/m³ |

Bond Strength | PVC sheets/ aluminium sheets> 80kpa cement mortar sheets>60 |

Shear strength | ≥ 80 |

Dimensional stability(23±2)°C | <5%< span=""> |

Heatconducting coefficient, 35°C | <0.02w/(m.k) |

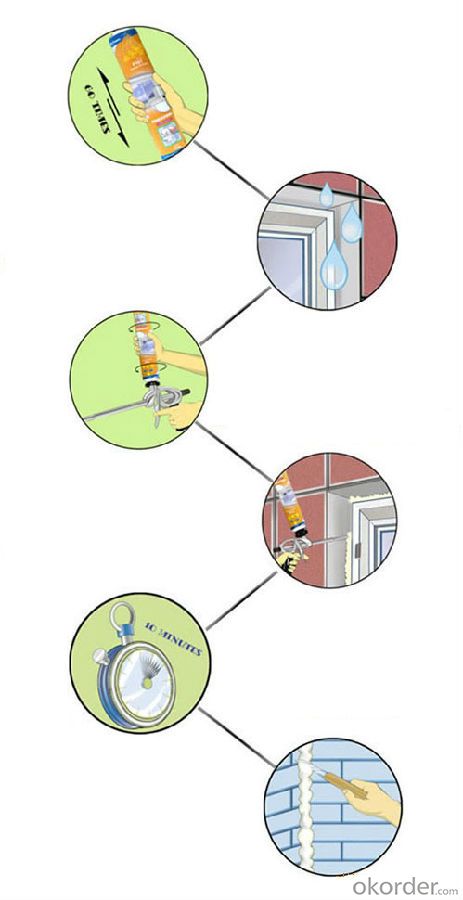

Guide for use

1. It can be applied to damp surfaces.

2. OCF is moisture curing.The more moisture, the quicker the cure.

3. It must be protected from Uvin External application to prevent discoloration and deterioration of foam.

4. Conventional paints can be applied to the foam.

5. It can be used in temperature range of 5-40°C,

if in low temperature condition, we suggest that it should be placed in 25-30°C

circumstance for 30 minutes to ensure the better performance.

6. Uncured foam can be removed with solvent. But after cure, foam can only be removed mechanically.

Uncured foam sticks to hands and clothing.

SAFETY RECOMMENDATION:

1) Do not breathe spray/vapor; In case of eye contact, flush with water and get immediate medical attention.

2) Wear suitable protective clothing, gloves and goggles.

3) Keep away from direct sunlight and do not expose temperatures over 50°C.

4) Keep out of the reach of children.