Rock Wool 1770°C Refractoriness <2000 High Temperature Fireproof Dense High Alumina

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | 1.On wooden pallets with plastic cover:Wooden pallet size:930*930mm load weight of each pallet:1.5-2.0 tons 2.According to customer's demands |

| Delivery Detail: | within 30 days |

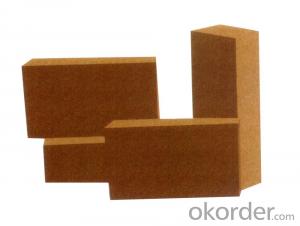

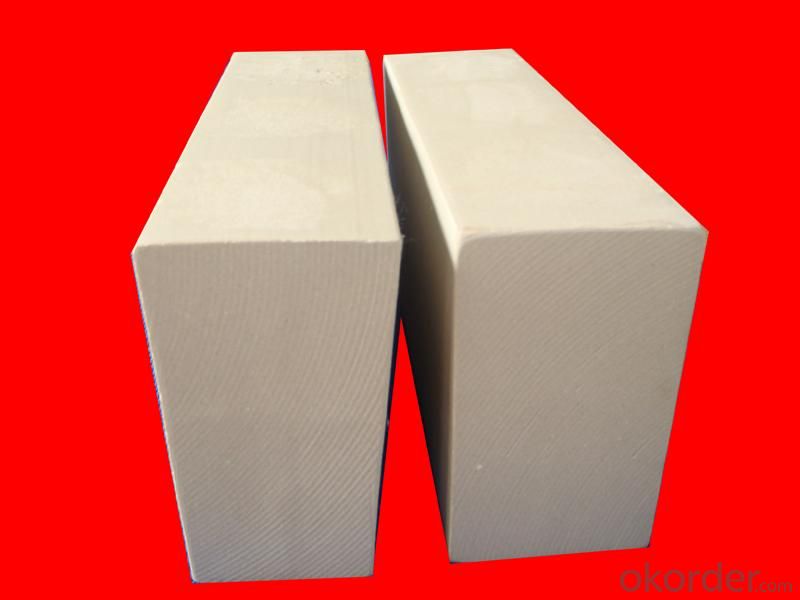

1770<Refractoriness<2000 High temperature fireproof dense high alumina refractory brick for furnace/kiln

Product Description

1.Description

High alumina refractory brick contain Al2O3 more than 48%, which is made of high grade bauxite through high temperature calcinations. Its refractories is usually above 1770 °C. The main mineral components are corundum and mullite phases. It is a kind of neutral refractory material so that it enjoys excellent resistance to acid and alkali corrosion. According to Al2O3 content,it can be divided into three degrees:The Al2O3 content is more than 75%.The Al2O3 content range from 60% to 75%.The Al2O3 content range from 48% to 60%.

2.Feature

1. High-temperature endurable .

2.Good thermal shock resistance.

3.High cold crushing strength

4.Good resistance to abrasion and corrosion.

5.Good thermal spalling resistance.

6.High mechanical strength.

7.Good volume stability at high temperature.

3.Technical Data

Item | Index | ||||

International code name | SK35 | SK36 | SK37 | SK38 | SK40 |

Al2O3 % | ≥48 | ≥55 | ≥65 | ≥75 | ≥80 |

Fe2O3 % | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

Refractoriness °C | ≥1750 | ≥1770 | ≥1790 | ≥1790 | ≥1790 |

Apparent porosity % | ≤22 | ≤22 | ≤23 | ≤23 | ≤21 |

Cold crushing strength Mpa | ≥39 | ≥44 | ≥49 | ≥54 | ≥65 |

Refractoriness under load(0.2MPa) °C | ≥1420 | ≥1470 | ≥1500 | ≥1520 | ≥1530 |

Reheating Linear Change (1500°C 2h) % | +0.1~ -0.4 *1450°C | +0.1~ -0.4 | +0.1~ -0.4 | +0.1~ -0.4 | +0.1~ -0.4 |

4.Application

High Alumina refractory Brick Application | |

Iron & steel making industry | Such as blast furnace,hot blast furnace(stove),pellet shaft furnace,hot metal ladle,steel ladle, tundish,heating furnace,soaking pit furnace,heat treatment furnace,refining furnace,reheating furnace,metal mixter furnace,annealing furnace, cupola furnace,electric arc furnace,induction furnace,AOD furnace,VOD furnace,etc thermal technology equipment . |

Non-ferrous Metal industry | Such as smelting furnace,refining furnace,reverberatory furnace,converter furnace, |

Building materials industry | Such as cement kiln,glass kiln,ceramic kiln, lime kilns, kiln car,tunnel kiln |

Energy & Incineration | Such as coke oven,general boiler,power generation boiler,circulating fluidized bed boiler,electric furnace,carbonroasting furnace,waste incinerators |

Others | Petrochemical industry furnace |

- Q: What does the rock wool board look like?

- The initial development of Hebei Langfang Dacheng in the building is a common type of application for industrial buildings should be consistent with "building insulation materials, the type of application and basic requirements"

- Q: What role does dolomite play in rock wool products?

- Pu hard foam layer can be firmly bonded with the base layer, the adhesive strength can exceed the tear strength of the foam itself, so Pu hard foam and the formation of the base layer, easy to delamination, to avoid the water along the interlayer

- Q: Rock wool products are divided into several categories

- In the rock wool by adding special adhesive can be processed into rock wool board, rock wool stave, rock wool insulation and other products, as the building insulation, insulation, cold, sound-absorbing material

- Q: How to judge the quality of rock wool

- Rock wool products, the important content of rock wool products, the density range is kg / m3 100-250 ± 15%, in this density of rock wool board to meet product quality requirements

- Q: The difference between rock wool and rock wool

- Yanmian tube with high strength and good flexibility, with a certain pressure, the pleated treatment of rock wool tube with a large drawing strength, not easy to layer, greatly improving the durability of the durability

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- No, rock wool is ore blown wire, aluminum silicate is coke gem

- Q: Rock wool insulation material fire rating is how much

- With low thermal conductivity, the use of high temperature, fire non-flammable, construction convenience, energy-saving effect is remarkable, there is a high cost performance. Adiabatic with rock wool, mineral wool and its products for a variety of pipe insulation and fire protection

- Q: Rock wool board is inorganic composite insulation material

- Rock wool products are inorganic insulation materials

Send your message to us

Rock Wool 1770°C Refractoriness <2000 High Temperature Fireproof Dense High Alumina

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords