All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do geomembranes contribute to the prevention of methane gas emissions from landfills?

Geomembranes are impermeable barriers made of synthetic materials that are used to line landfills. By creating a barrier between the waste and the surrounding environment, geomembranes help to prevent the escape of methane gas from landfills. Methane gas is a potent greenhouse gas that is produced as organic waste decomposes in landfills. By effectively containing the waste and its gases, geomembranes contribute to the prevention of methane gas emissions, reducing the environmental impact and potential health risks associated with these emissions.

Can geomembranes be used for landfill gas-to-energy projects?

Yes, geomembranes can be used for landfill gas-to-energy projects. Geomembranes are impermeable liners that are often used to contain and manage landfill waste. In the context of landfill gas-to-energy projects, geomembranes can help to capture and control the release of landfill gases, such as methane. These gases can then be extracted and utilized to generate energy through processes like anaerobic digestion or combustion. The use of geomembranes can therefore enhance the efficiency and sustainability of landfill gas-to-energy projects.

What are the considerations for geomembrane installation in high wind areas?

When installing geomembranes in high wind areas, several considerations must be taken into account. Firstly, it is essential to select a geomembrane material that is suitable for high wind conditions, such as a reinforced or high-strength membrane. The design of the geomembrane installation should also include additional anchoring methods, such as using sandbags or concrete weights, to prevent the membrane from being lifted or damaged by strong winds. Additionally, proper tensioning and securing of the geomembrane is crucial to ensure its stability and prevent wind-induced damage. Regular inspections and maintenance should also be conducted to identify any issues or weaknesses in the installation that could be exacerbated by high winds. Finally, it is important to consult with experienced professionals or engineers who are knowledgeable about geomembrane installations in high wind areas to ensure the project's success and longevity.

What is the lifespan of a geomembrane liner in a pond or reservoir?

The lifespan of a geomembrane liner in a pond or reservoir can vary depending on various factors such as the type and quality of the liner material, installation techniques, environmental conditions, and the level of maintenance. Generally, a properly installed and maintained geomembrane liner can last anywhere from 20 to 40 years or even longer.

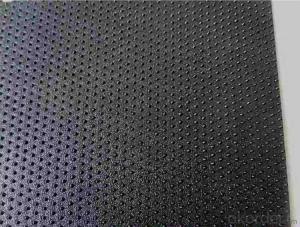

Wholesale Geomembranes from supplier in Ukraine

We understand the importance of quality and reliability in the Geomembranes industry, and we are committed to delivering the best products to our customers. All of our Geomembranes are manufactured using high-quality materials and undergo rigorous testing to ensure their strength and durability.

In addition to our wide range of products, we also offer customized solutions to meet your specific project needs. Our team of experts will work closely with you to understand your requirements and provide tailored recommendations. Whether you need a Geomembrane for a landfill, mining operation, or water containment project, we have the expertise to assist you.

Furthermore, we take pride in our excellent customer service. We strive to build long-term relationships with our clients and prioritize their satisfaction. Our dedicated sales team is available to answer any questions you may have and provide prompt assistance.

When you choose us as your Geomembranes supplier in Ukraine, you can trust that you will receive top-quality products, reliable service, and technical support. We have a proven track record of successfully completing projects of all sizes and complexities, and we look forward to working with you to achieve your goals.

Contact us today to learn more about our Geomembranes products and services and let us become your trusted partner in Ukraine.

In addition to our wide range of products, we also offer customized solutions to meet your specific project needs. Our team of experts will work closely with you to understand your requirements and provide tailored recommendations. Whether you need a Geomembrane for a landfill, mining operation, or water containment project, we have the expertise to assist you.

Furthermore, we take pride in our excellent customer service. We strive to build long-term relationships with our clients and prioritize their satisfaction. Our dedicated sales team is available to answer any questions you may have and provide prompt assistance.

When you choose us as your Geomembranes supplier in Ukraine, you can trust that you will receive top-quality products, reliable service, and technical support. We have a proven track record of successfully completing projects of all sizes and complexities, and we look forward to working with you to achieve your goals.

Contact us today to learn more about our Geomembranes products and services and let us become your trusted partner in Ukraine.