All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

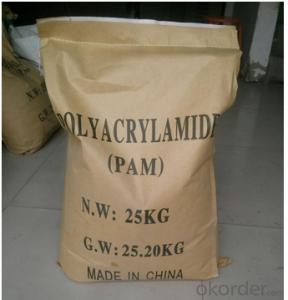

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different types of polymer blends and composites?

There are several types of polymer blends and composites, including immiscible blends, miscible blends, interpenetrating polymer networks (IPNs), and filled composites. Immiscible blends refer to two or more polymers that do not mix at a molecular level, resulting in phase separation. Miscible blends, on the other hand, involve polymers that are compatible and mix uniformly at the molecular level. IPNs consist of two or more polymers that are chemically crosslinked, forming a network structure. Filled composites involve the addition of fillers, such as fibers or nanoparticles, to enhance the properties of the polymer matrix.

What are the advantages and disadvantages of using biodegradable polymers?

The advantages of using biodegradable polymers include their ability to break down naturally over time, reducing environmental pollution and waste accumulation. They also have potential applications in various industries, such as packaging, agriculture, and medicine. However, some disadvantages include their higher production costs compared to non-biodegradable polymers, limited mechanical properties, and the requirement for specific environmental conditions for proper degradation. Additionally, the availability of proper waste management infrastructure and consumer awareness are crucial for maximizing the benefits of biodegradable polymers.

What is a filler?

A filler is a word, phrase, or sound used in speech to fill pauses, hesitations, or gaps in conversation without adding any significant meaning or content.

Wholesale Polymer from supplier in Sweden

Whether you are in the construction, automotive, packaging, or any other industry requiring Polymer products, we have the solutions to meet your specific needs. Our Polymer product range includes but is not limited to:

1. Polyethylene (PE): We offer various grades of PE, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE). These products are widely used in applications such as pipes, films, and packaging materials.

2. Polypropylene (PP): Our PP products are available in different grades, including homopolymer, random copolymer, and block copolymer. These materials are commonly used in automotive parts, appliances, and packaging applications.

3. Polystyrene (PS): We provide both general-purpose polystyrene (GPPS) and high-impact polystyrene (HIPS) products. GPPS is often used in food packaging, while HIPS is suitable for applications requiring higher impact resistance, such as electronic casings.

4. Polyvinyl Chloride (PVC): Our PVC products are suitable for a wide range of applications, including pipes, profiles, and electrical insulation. We offer both rigid and flexible PVC options, depending on your requirements.

5. Polyethylene Terephthalate (PET): PET is commonly used in the production of bottles for beverages, food packaging, and polyester fibers. We offer PET products of various grades to meet different specifications.

In addition to our extensive product range, we provide comprehensive sales, quotation, and technical support services to ensure a smooth procurement process. Our team of experts is ready to assist you in selecting the right Polymer products for your projects and providing guidance on their proper usage.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast global network and resources. This enables us to offer competitive pricing, reliable supply chains, and efficient logistics services to our customers in Sweden.

We are dedicated to fostering long-term partnerships with our clients and strive to exceed their expectations in terms of product quality, customer service, and technical support. Contact us today to discuss your Polymer product requirements and discover how our expertise can enhance the success of your projects in Sweden.

1. Polyethylene (PE): We offer various grades of PE, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE). These products are widely used in applications such as pipes, films, and packaging materials.

2. Polypropylene (PP): Our PP products are available in different grades, including homopolymer, random copolymer, and block copolymer. These materials are commonly used in automotive parts, appliances, and packaging applications.

3. Polystyrene (PS): We provide both general-purpose polystyrene (GPPS) and high-impact polystyrene (HIPS) products. GPPS is often used in food packaging, while HIPS is suitable for applications requiring higher impact resistance, such as electronic casings.

4. Polyvinyl Chloride (PVC): Our PVC products are suitable for a wide range of applications, including pipes, profiles, and electrical insulation. We offer both rigid and flexible PVC options, depending on your requirements.

5. Polyethylene Terephthalate (PET): PET is commonly used in the production of bottles for beverages, food packaging, and polyester fibers. We offer PET products of various grades to meet different specifications.

In addition to our extensive product range, we provide comprehensive sales, quotation, and technical support services to ensure a smooth procurement process. Our team of experts is ready to assist you in selecting the right Polymer products for your projects and providing guidance on their proper usage.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast global network and resources. This enables us to offer competitive pricing, reliable supply chains, and efficient logistics services to our customers in Sweden.

We are dedicated to fostering long-term partnerships with our clients and strive to exceed their expectations in terms of product quality, customer service, and technical support. Contact us today to discuss your Polymer product requirements and discover how our expertise can enhance the success of your projects in Sweden.

Hot Search

- Fiberglass Chopped Strand in Portugal

- Fiberglass Mesh Cloth in Somalia

- Composite Pipes in Bangladesh

- FRP Pultrusion Profiles in Mauritania

- Fiberglass Mat Tissue in Malaysia

- Fiberglass Fabrics in Gabon

- Fiberglass Mesh in Kazakhstan

- Composite Tank in Cyprus

- Fiberglass Mesh tape in Kenya

- Polymer in Poland