All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

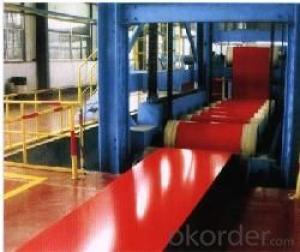

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel strips processed in terms of slitting and shearing?

Steel strips are processed through slitting and shearing techniques to achieve the desired width and length. Slitting involves cutting the steel strip into narrower widths, while shearing is used to trim the strip to the required length. Both processes involve precise cutting machinery and careful handling to ensure accurate dimensions and smooth edges.

What are the implications of steel strip thickness on material flexibility and strength?

The steel strip thickness has significant implications on material flexibility and strength. A thicker steel strip generally results in higher strength but reduced flexibility. Thicker strips are more resistant to bending and deformation, making them suitable for applications that require structural integrity and load-bearing capacity. However, they may be less pliable and have limited flexibility, which can restrict their use in certain applications that require bending or shaping. On the other hand, thinner steel strips offer greater flexibility but may sacrifice some strength. Consequently, the choice of steel strip thickness should be carefully considered to ensure that the material meets the specific requirements and demands of the intended application.

What are the advancements in the use of steel strips for the production of sustainable building materials?

The advancements in the use of steel strips for the production of sustainable building materials have been significant. Steel strips are now being used in various innovative ways to create eco-friendly construction materials. One major advancement is the development of galvanized steel strips, which have a protective zinc coating that enhances their durability and resistance to corrosion. This makes them ideal for long-lasting building materials that require minimal maintenance. Additionally, advancements in manufacturing processes have led to the production of thinner and lighter steel strips, reducing material waste and transportation costs. Furthermore, the use of recycled steel in the production of these strips has contributed to the sustainability of the construction industry by reducing the demand for virgin steel. Overall, these advancements in the use of steel strips have greatly contributed to the production of sustainable building materials, promoting eco-conscious construction practices.

Wholesale Steel Strips from supplier in Namibia

We are a Steel Strips supplier serving the Namibia, mainly engaged in the sale, quotation, and technical support services of various Steel Strips products in the Namibia region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Strips procurement services in the Namibia. Not only do we have a wide range of Steel Strips products, but after years of market development in the Namibia, we can also provide valuable experience for your projects.