All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

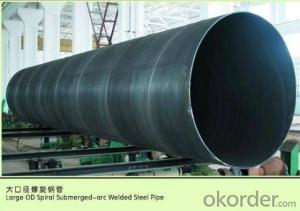

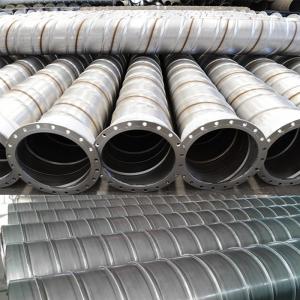

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different sizes available for welded steel pipe?

The different sizes available for welded steel pipe vary depending on the specific needs and requirements of the project. However, common sizes range from 1/2 inch to 48 inches in diameter, with varying wall thicknesses. It is important to consult industry standards and specifications to determine the appropriate size for a specific application.

Can welded steel pipe be used for marine applications?

Yes, welded steel pipe can be used for marine applications. Welded steel pipe is commonly used in various marine applications such as offshore oil rigs, shipbuilding, and underwater pipelines. Its durability, strength, and resistance to corrosion make it suitable for withstanding the harsh conditions of the marine environment. Additionally, welded steel pipe can be customized to meet specific project requirements, making it a versatile choice for marine applications.

What are the factors that affect the noise level of fluid flow in welded steel pipes?

The factors that affect the noise level of fluid flow in welded steel pipes include the velocity of the fluid, the diameter and thickness of the pipe, the presence of any obstructions or irregularities in the flow, the type and viscosity of the fluid, and the overall design of the piping system.

What are the factors that affect the lifespan of a welded steel pipe?

There are several factors that can affect the lifespan of a welded steel pipe. Some key factors include the quality of the weld itself, the type of steel used, the environmental conditions in which the pipe is installed, and the level of maintenance and care given to the pipe over time. Additionally, factors such as corrosion, presence of chemicals or harsh substances, and the overall structural design and integrity of the pipe can also impact its lifespan.

What is the impact of hardness on the durability and wear resistance of welded steel pipe?

The hardness of welded steel pipe has a significant impact on its durability and wear resistance. A higher hardness level generally indicates a stronger and more durable pipe, capable of withstanding greater stress and wear. Hardness also affects the pipe's resistance to deformation, such as denting or bending, as well as its ability to resist abrasion and corrosion. Therefore, a harder welded steel pipe is generally more durable and offers better wear resistance compared to a softer one.

Wholesale Welded Steel Pipe from supplier in Haiti

We are a Welded Steel Pipe supplier serving the Haiti, mainly engaged in the sale, quotation, and technical support services of various Welded Steel Pipe products in the Haiti region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Welded Steel Pipe procurement services in the Haiti. Not only do we have a wide range of Welded Steel Pipe products, but after years of market development in the Haiti, we can also provide valuable experience for your projects.