All Categories

- - Steel Wire Rod

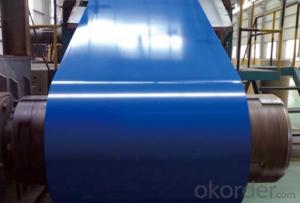

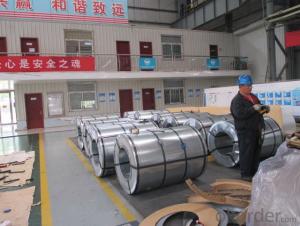

- - Steel Coils

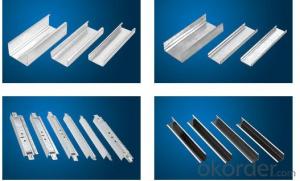

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different annealing techniques for stainless steel coils?

There are several annealing techniques commonly used for stainless steel coils, including solution annealing, full annealing, and stress relieving annealing. Solution annealing involves heating the coils to a high temperature, typically around 1040°C, and then cooling them rapidly to enhance their corrosion resistance. Full annealing, on the other hand, involves heating the coils to a temperature between 760°C and 830°C and then cooling them slowly to improve their ductility and toughness. Stress relieving annealing is performed at a lower temperature, typically around 550°C, to reduce residual stresses in the coils and prevent distortion or cracking.

What is the minimum coil ID for stainless steel coil?

The minimum coil ID for stainless steel coil typically ranges from 16 inches to 20 inches, depending on the specific product and manufacturer.

How do you clean and maintain stainless steel coils?

To clean and maintain stainless steel coils, start by disconnecting the power supply and allowing the coils to cool down. Next, use a soft brush or cloth to remove any loose debris or dust from the coils. If there are stubborn stains or dirt, you can mix a mild detergent with warm water and gently scrub the coils. Avoid using abrasive cleaners or scrubbers as they can damage the stainless steel surface. Rinse the coils thoroughly with clean water and dry them completely before reconnecting the power supply. Regularly checking and cleaning the coils can help improve their efficiency and prolong their lifespan.

Can stainless steel coils be used in high-temperature creep applications?

Yes, stainless steel coils can be used in high-temperature creep applications. Stainless steel is known for its excellent heat resistance and creep resistance, making it suitable for applications where materials are subjected to high temperatures and prolonged stress over time. The alloy composition and heat treatment processes of stainless steel coils can further enhance their ability to withstand high-temperature creep conditions. However, it is important to carefully select the appropriate grade and ensure proper design and installation to ensure optimal performance and longevity in such applications.

How does quenching and tempering affect the performance of a stainless steel coil?

Quenching and tempering processes significantly enhance the performance of a stainless steel coil. Quenching involves rapid cooling of the steel, which increases its hardness, strength, and wear resistance. This process helps to create a strong and durable coil that can withstand harsh conditions and heavy loads. Tempering, on the other hand, involves reheating the quenched steel to a specific temperature and then slowly cooling it down. This step reduces the brittleness caused by quenching and improves the coil's toughness and flexibility. Overall, quenching and tempering improve the mechanical properties of the stainless steel coil, making it more reliable and suitable for various applications.

Wholesale Stainless Steel Coil from supplier in Bengal

Whether you need Stainless Steel Coils for industrial applications or construction projects, we have the right solution for you. Our product range includes various grades and finishes, such as 304, 316, 430, and more, to cater to diverse needs.

At CNBM, we understand the importance of quality and reliability. That's why we source our Stainless Steel Coils from renowned manufacturers, ensuring that each product meets international standards. Our rigorous quality control procedures guarantee that only the best coils reach our customers in Bengal.

In addition to our extensive product range, we offer a range of value-added services to enhance your experience. Our team of experts is dedicated to providing exceptional customer service, assisting you with product selection, technical support, and any queries you may have. We strive to deliver prompt and reliable services, ensuring that your project requirements are met efficiently.

As a subsidiary of CNBM, we benefit from the vast resources and network of a Fortune Global 500 company. This enables us to offer competitive prices without compromising on quality. Our strong supply chain management ensures that your orders are delivered on time, every time.

Partner with us for all your Stainless Steel Coil needs in Bengal and experience the CNBM advantage. We are committed to providing top-notch products, unmatched customer service, and a hassle-free procurement process. Contact us today to discuss your requirements and let us be your trusted supplier in the Bengal region.

At CNBM, we understand the importance of quality and reliability. That's why we source our Stainless Steel Coils from renowned manufacturers, ensuring that each product meets international standards. Our rigorous quality control procedures guarantee that only the best coils reach our customers in Bengal.

In addition to our extensive product range, we offer a range of value-added services to enhance your experience. Our team of experts is dedicated to providing exceptional customer service, assisting you with product selection, technical support, and any queries you may have. We strive to deliver prompt and reliable services, ensuring that your project requirements are met efficiently.

As a subsidiary of CNBM, we benefit from the vast resources and network of a Fortune Global 500 company. This enables us to offer competitive prices without compromising on quality. Our strong supply chain management ensures that your orders are delivered on time, every time.

Partner with us for all your Stainless Steel Coil needs in Bengal and experience the CNBM advantage. We are committed to providing top-notch products, unmatched customer service, and a hassle-free procurement process. Contact us today to discuss your requirements and let us be your trusted supplier in the Bengal region.