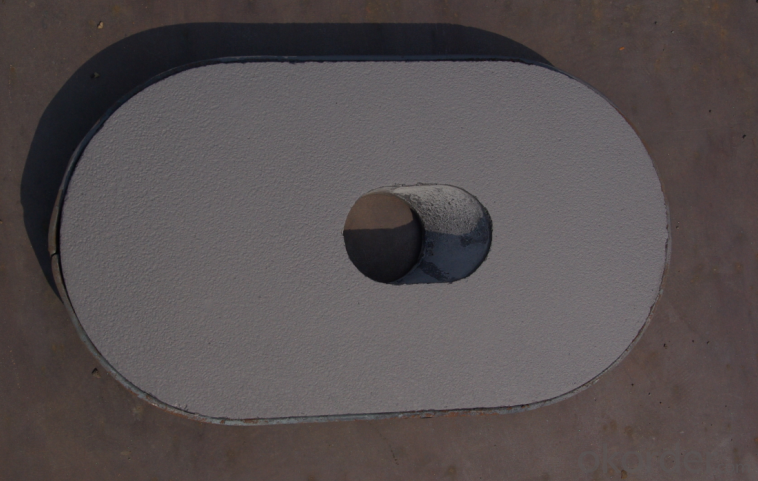

Zirconia Slide Gate Nozzle for Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Zirconia Slide Gate Nozzle for Steel Industry

Slide gate plate widely used in large ladle, middle ladle and small ladle to fit for high quality steel casting.

Slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Burnt Slide gate

Item B60,B50,C40type | Al-C Slide Gate | Al-Zr-C Slide Gate | ||||||

AlC-70 | AlC -75 | AlC -80 | AlC-85 | AlC -86 | AlZrC -70 | AlZrC-75 | AlZrC -77 | |

Al2O3,% | 70 | 75 | 80 | 85 | 86 | 70 | 75 | 77 |

C+SiC,% | 7 | 7 | 5 | 5 | 4 | 7 | 7 | 7 |

ZrO2,% | - | - | - | - | - | 6 | 6 | 2.5 |

A.P.,% max | 10 | 10 | 10 | 10 | 7 | 10 | 10 | 10 |

B.D.,g/cm3 | 2.8 | 2.9 | 2.9 | 3.0 | 2.95 | 3.00 | 3.05 | 2.90 |

C.C.S., MPa min | 65 | 70 | 100 | 100 | 100 | 110 | 115 | 100 |

Unburned compound AlC Slide gate

Item B60,B50,C40type | Al-C Slide Gate | ||||

AlC-70A | AlC-75A | AlC-80A | AlC-85A | AlC-86A | |

Al2O3,% | 70 | 75 | 80 | 85 | 86 |

C,% | 7 | 7 | 5 | 5 | 4 |

A.P.,% max | 10 | 10 | 8 | 10 | 7 |

B.D. g/cm3 min | 2.8 | 2.9 | 3.0 | 3.0 | 2.95 |

C.C.S., MPa min | 65 | 70 | 100 | 100 | 100 |

zirconium core :

Item | ZN- 65 | ZN- 70 | ZN- 75 | ZN- 80 | ZN- 85 | ZN- 90 | ZN- 93A | ZN- 93B | ZN- 93C | ZN- 93D | ZN- 95A | ZN- 95B | ZN- 96 |

ZrO2(%) | ≥65 | ≥70 | ≥75 | ≥80 | ≥85 | ≥90 | ≥93 | ≥93 | ≥93 | ≥93 | ≥95 | ≥95 | ≥96 |

Bulk density (g/cm3) | ≥3.8 | ≥3.8 | ≥3.9 | ≥4.0 | ≥4.1 | ≥4.3 | ≥5.1 | ≥4.9 | ≥4.7 | ≥4.4 | ≥4.6 | ≥5.2 | ≥5.2 |

Apparent Porosity(%) | ≤23 | ≤22 | ≤22 | ≤20 | ≤20 | ≤20 | ≤13 | ≤15 | ≤18 | ≤20 | ≤20 | ≤9 | ≤5.6 |

Thermal shock resistance (cycles)(1100℃,water cooling) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >8 | >10 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What are the specific requirements of monolithic refractories for continuous casting applications?

- To withstand the extreme temperatures and thermal shock conditions experienced during continuous casting, monolithic refractories have specific requirements. First and foremost, these refractories must possess high thermal conductivity, enabling them to efficiently transfer heat away from the molten metal and maintain a stable casting temperature. This is crucial in preventing the formation of defects such as cracks, hot spots, and uneven solidification in the cast product. Secondly, monolithic refractories for continuous casting applications need to exhibit high refractoriness. This means they can endure the high temperatures of the molten metal without melting or deforming, ensuring the refractories can provide a protective lining and maintain their structural integrity throughout the casting process. In addition, these refractories must demonstrate excellent resistance to thermal shock. The continuous casting process involves rapid cooling and heating cycles, resulting in significant temperature differentials and inducing thermal stresses. Monolithic refractories with low thermal expansion and high thermal shock resistance can endure these conditions without cracking or spalling. Moreover, good erosion and corrosion resistance are vital requirements for monolithic refractories in continuous casting applications. The molten metal and slag can be highly corrosive and abrasive, causing wear and chemical attack on the refractory lining. Therefore, refractories with high resistance to erosion and corrosion are essential to ensure the longevity and stability of the lining. Lastly, monolithic refractories for continuous casting applications should possess good workability and ease of installation. This allows for efficient and precise lining installation, minimizing downtime during maintenance or repairs. Overall, the specific requirements for monolithic refractories in continuous casting encompass high thermal conductivity, refractoriness, thermal shock resistance, erosion and corrosion resistance, as well as good workability. Fulfilling these requirements guarantees that the refractories effectively safeguard the casting equipment and maintain the quality of the cast products.

- Q:What are the different techniques for installing monolithic refractories?

- Installing monolithic refractories can be accomplished using various techniques, each with its own advantages and suitability for different applications. Some commonly employed methods are as follows: 1. Casting: This involves creating a slurry by mixing the refractory material with water or a binder. The resulting mixture is then poured into molds or directly onto the prepared surface. Once set and hardened, it forms a solid monolithic structure. 2. Gunning: By utilizing a gunning machine, the refractory material is sprayed onto the surface. The material is combined with water or a binder to form a wet mix, which is then propelled onto the surface at high velocity. Gunning is commonly used for on-site repairs or lining larger areas. 3. Ramming: In this technique, the refractory material is compacted into place using a pneumatic or manual ramming tool. Prior to ramming, the material is typically preheated to decrease moisture content and enhance workability. Ramming is often employed for lining smaller areas or filling gaps between bricks or precast shapes. 4. Shotcreting: Similar to gunning, shotcreting involves using a dry mix of refractory material. The dry mix is combined with water or a binder just before being sprayed onto the surface using a high-pressure nozzle. Shotcreting is frequently used for lining larger areas or creating intricate shapes. 5. Troweling: This technique entails applying the refractory material onto the surface using a trowel or similar tool. The material used is typically a wet mix that is spread and smoothed manually. Troweling is commonly employed for patching or repairing small areas, as well as for adding finishing touches. 6. Vibrating: By using a vibrating tool or vibrator, the refractory material is compacted and any air pockets are eliminated. Vibrating is often used to improve the density and strength of the monolithic refractory after it has been installed using other techniques. It is essential to consider various factors, such as the type of refractory material, the size and shape of the area to be lined, and the specific requirements of the application when selecting the appropriate technique. Additionally, proper surface preparation and adherence to installation guidelines are crucial to ensure the effectiveness and longevity of the monolithic refractory.

- Q:What are the latest advancements in monolithic refractories for the iron and steel industry?

- Some of the latest advancements in monolithic refractories for the iron and steel industry include the development of high-performance materials with enhanced thermal shock resistance, improved corrosion resistance, and increased durability. These advancements have been achieved through the incorporation of advanced additives and binders, as well as the utilization of new manufacturing techniques such as spray drying and rapid heat curing. Additionally, there have been advancements in the design of monolithic refractory shapes and installation techniques to optimize their performance and increase their lifespan in the demanding environments of the iron and steel industry.

- Q:Can monolithic refractories be used for the lining of ladle refining furnaces and VOD converters?

- Yes, monolithic refractories can be used for the lining of ladle refining furnaces and VOD converters. Monolithic refractories are versatile and can be shaped and installed easily, making them suitable for lining various types of furnaces and converters, including ladle refining furnaces and VOD converters.

- Q:How do monolithic refractories contribute to the reduction of heat loss in iron and steel furnaces?

- Reducing heat loss in iron and steel furnaces is a crucial role played by monolithic refractories. These refractories are specifically designed to create a seamless lining throughout the furnace, eliminating any joints or seams that could result in thermal leaks. Monolithic refractories effectively contribute to heat loss reduction in two ways. Firstly, they possess excellent thermal insulation properties that restrict the transfer of heat from the furnace to its surroundings. With their low thermal conductivity, they effectively maintain the high temperatures required for efficient iron and steel production within the furnace, while minimizing heat loss to the surrounding environment. Secondly, monolithic refractories act as a protective barrier, preventing the escape of hot gases and molten metal. This barrier ensures the integrity of the furnace lining, preventing any gaps or cracks that could allow heat to escape. By creating a tight and continuous lining, monolithic refractories significantly reduce heat loss by keeping the heat contained within the furnace. Furthermore, monolithic refractories exhibit a high resistance to thermal shock and erosion, which are common challenges faced in iron and steel furnaces. These refractories can withstand rapid temperature changes, preventing sudden cracks or failures that could result in heat loss. Additionally, they are resistant to the corrosive effects of molten metal and hot gases, guaranteeing the longevity of the lining and preserving its insulating properties over time. To summarize, monolithic refractories contribute to the reduction of heat loss in iron and steel furnaces through their exceptional thermal insulation properties, ability to provide a continuous lining, resistance to thermal shock and erosion, and protection against corrosive substances. By minimizing heat loss, these refractories optimize energy efficiency and productivity in the furnace, leading to cost savings and improved overall performance in the iron and steel industry.

- Q:What are the specific requirements of monolithic refractories for soaking pit applications?

- The specific requirements of monolithic refractories for soaking pit applications are primarily aimed at withstanding high temperatures and thermal cycling, as well as providing excellent resistance to chemical attacks and mechanical stresses. Firstly, monolithic refractories used in soaking pits need to have a high temperature resistance capability, as these pits are subjected to extreme heat conditions. They should be able to withstand continuous exposure to temperatures exceeding 1500 degrees Celsius without any significant degradation. This is crucial to ensure the longevity and durability of the refractories. Secondly, thermal cycling is a common occurrence in soaking pit applications. The refractories should possess good thermal shock resistance to handle rapid changes in temperature. This prevents cracking and spalling, which can compromise the integrity of the refractories. Chemical attacks are also a concern in soaking pit applications due to the presence of molten metal, slag, and other corrosive substances. The refractories used should have excellent chemical resistance to prevent erosion and chemical reactions. They should be able to resist the corrosive effect of molten metal and slag, as well as any potential chemical reactions with these substances. Furthermore, soaking pits involve mechanical stresses, such as abrasion and impact, due to the handling and movement of metal ingots. The monolithic refractories must have good mechanical strength and abrasion resistance to withstand these stresses. They should be able to resist wear and tear caused by the movement of heavy loads and prevent any mechanical failure. Lastly, the refractories used in soaking pits should have good workability and ease of installation. This allows for efficient and effective lining of the pit, ensuring a proper seal and minimizing any gaps or cracks that could lead to heat loss or chemical penetration. Overall, the specific requirements of monolithic refractories for soaking pit applications revolve around high temperature resistance, thermal shock resistance, chemical resistance, mechanical strength, and ease of installation. Meeting these requirements ensures the refractories can withstand the harsh conditions of soaking pits and maintain their performance and integrity over an extended period.

- Q:What are the key factors to consider when designing the lining system with monolithic refractories?

- To ensure optimal performance and longevity of the lining, several key factors must be taken into account when designing a system with monolithic refractories. These factors include: 1. Material selection: It is crucial to choose the appropriate monolithic refractory material, considering factors such as operating temperature, chemical environment, and mechanical stress. Different materials have varying properties and performance characteristics, so selecting the most suitable one for the specific application is essential. 2. Thermal expansion: Like any other material, monolithic refractories expand and contract with temperature changes. Therefore, it is important to consider the thermal expansion properties and how they will interact with the surrounding structure. To prevent cracking or spalling, proper expansion joints or design features should be incorporated. 3. Installation technique: The method of installation plays a critical role in the lining system's performance. Following the manufacturer's guidelines for mixing, placing, and curing the refractory material is essential. Improper installation can compromise lining integrity, thermal conductivity, and structural stability. 4. Bonding and anchoring: To ensure effective lining performance, a strong bond between the monolithic refractory and the substrate is necessary. Proper surface preparation, suitable bonding agents, and appropriate anchoring techniques should be considered to enhance adhesion and stability. 5. Structural design: The structural design of the lining system should be carefully planned to withstand mechanical stresses and operational conditions. Load-bearing capacity, thermal shock resistance, and thermal cycling must be taken into consideration during the design phase. Reinforcement materials, such as steel fibers or mesh, may be required to enhance structural integrity and prevent cracking or spalling. 6. Maintenance and repair: Anticipating the need for maintenance and repair is crucial for the lining system's longevity. Access points, inspection ports, and repair techniques should be considered. Regular inspections and proactive maintenance can help identify and address issues before they escalate and cause major failures. By considering these key factors, a well-designed and effective lining system with monolithic refractories can be ensured, capable of withstanding harsh conditions and providing long-term performance.

- Q:What are the challenges in recycling monolithic refractories?

- One of the main challenges in recycling monolithic refractories is their composition. Monolithic refractories are typically made from a combination of different minerals, binders, and additives, which can make the separation and recovery of individual components difficult. Additionally, the high temperatures at which monolithic refractories are used can cause chemical reactions and physical changes that affect their recyclability. Furthermore, the presence of contaminants, such as metal oxides or impurities from the manufacturing process, can also pose challenges in the recycling process. Overall, developing efficient and cost-effective recycling methods for monolithic refractories requires addressing these challenges and finding innovative solutions.

- Q:How do monolithic refractories perform in torpedo ladle applications?

- Monolithic refractories are commonly used in torpedo ladle applications due to their excellent performance and durability. Torpedo ladles are used in the steelmaking process to transport and pour molten metal from the blast furnace to the steelmaking furnace. Monolithic refractories, also known as unshaped refractories, are made from a single material and can be applied as a single, cohesive mass. This makes them highly versatile and easy to install in the torpedo ladle. In torpedo ladle applications, monolithic refractories offer several advantages. First and foremost, they have high heat resistance, allowing them to withstand the extreme temperatures and thermal shocks experienced during the transfer and pouring of molten metal. This ensures that the refractories do not crack or fail under these harsh conditions. Additionally, monolithic refractories have excellent corrosion resistance properties, which is crucial in torpedo ladles where the molten metal can be highly corrosive. They are able to withstand the aggressive chemical environment and prevent chemical reactions that could lead to refractory deterioration. Moreover, monolithic refractories have good thermal insulation properties, reducing heat loss from the molten metal and promoting energy efficiency. This helps to maintain the desired temperature of the metal, ensuring optimal steelmaking conditions. Furthermore, monolithic refractories offer good mechanical strength and resistance to abrasion, making them highly suitable for torpedo ladle applications where the refractory lining is subjected to mechanical stress and wear. Overall, monolithic refractories perform exceptionally well in torpedo ladle applications due to their high heat resistance, corrosion resistance, thermal insulation properties, and mechanical strength. They are able to withstand the extreme conditions and provide a reliable and long-lasting lining for torpedo ladles in the steelmaking industry.

- Q:What are the key properties of pumpable refractories used for monolithic refractory applications?

- The key properties of pumpable refractories used for monolithic refractory applications include high flowability, good workability, excellent bonding strength, and high resistance to thermal shock. These pumpable refractories should also possess good pumpability and be able to withstand the intense heat and mechanical stress in the application environment. Additionally, they should have low water demand, high chemical resistance, and the ability to maintain their properties even after exposure to high temperatures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Zirconia Slide Gate Nozzle for Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords