Zinc Coating Steel Building Roof Walls Steel Coil ASTM 615-009

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.tungsten, carbon and so on. Basically, steel is an iron-carbon alloy that does not undergo eutectic reaction. In contrast,cast iron does undergo eutectic reaction, juveniles and non-breeding males have predominantly grey-brown plumage, but breeding males adopt brilliant colours, with an iridescent silvery-blue crown and upper back, red-brown shoulders, a black throat, grey-brown wings and pale underparts. Though the red-winged fairywren is locally common, there is evidence of a decline in numbers. Primarily insectivorous, it forages and lives in the shelter of scrubby vegetation in China.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

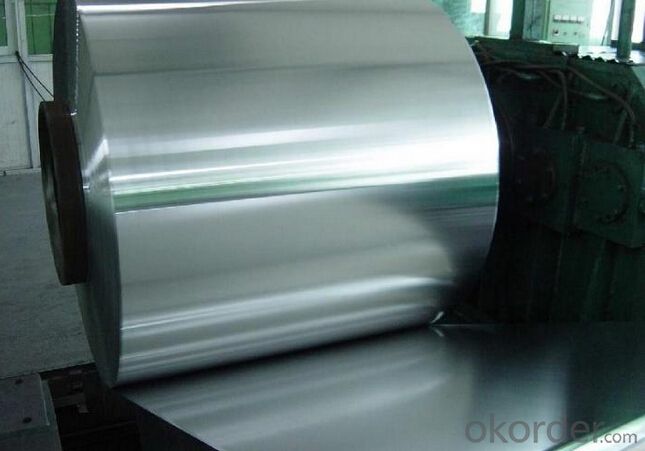

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:What is the length tolerance of steel strips?

- The length tolerance of steel strips can vary depending on the specific type and grade, but generally it is around ± 0.2% to ± 0.5% of the specified length.

- Q:How are steel strips used in the production of lighting fixtures?

- Steel strips are commonly used in the production of lighting fixtures for various purposes. One of the main uses of steel strips in lighting fixture production is for the creation of the fixture's body or housing. Steel strips are often shaped, bent, or molded into the desired form to create the structure of the lighting fixture. This provides durability, strength, and stability to the fixture, ensuring it can withstand the weight of the components and any external forces. Additionally, steel strips may also be used for the production of brackets or mounting plates that secure the lighting fixture to the ceiling or wall. These brackets are essential for the proper installation and positioning of the fixture, ensuring it remains securely fixed in place. In some cases, steel strips can also be used as decorative elements in the design of lighting fixtures. They can be shaped into intricate patterns, curves, or other designs to enhance the aesthetic appeal of the fixture. Furthermore, steel strips may be utilized to create reflectors or diffusers that help control the direction and intensity of light emitted from the fixture. These components are crucial for achieving the desired lighting effect and can be customized to meet specific requirements. Overall, steel strips play a vital role in the production of lighting fixtures by providing structural support, decorative elements, and functional components, ultimately contributing to the overall quality and functionality of the product.

- Q:What are the specifications for steel strips used in the production of wire ropes?

- The specifications for steel strips used in the production of wire ropes can vary depending on the specific application and requirements. However, there are some general specifications that are commonly followed in the industry. 1. Material: The steel strips used in wire rope production are typically made from high-quality carbon or alloy steel. These steels have excellent strength, ductility, and fatigue resistance characteristics. 2. Size and Dimensions: The dimensions of the steel strips may vary based on the desired wire rope size and construction. Common thicknesses range from 0.15 mm to 6 mm, while widths can range from 2 mm to 100 mm. 3. Surface Finish: The steel strips used in wire rope production should have a smooth and clean surface finish to ensure proper adhesion of lubricants and coatings. The surface should be free from defects, such as cracks, scratches, or rust. 4. Mechanical Properties: The steel strips should possess specific mechanical properties to ensure the wire rope's strength and durability. These properties include a high tensile strength, good elongation, and excellent fatigue resistance. The mechanical properties are usually specified by the manufacturer according to the wire rope's intended use. 5. Coating and Protection: To enhance corrosion resistance, steel strips used in wire rope production may be coated with zinc, galvanized, or treated with other corrosion-resistant coatings. The coating thickness and type may vary depending on the application and environmental conditions. 6. Certification and Compliance: The steel strips should meet certain industry standards and certifications, such as ASTM or ISO, to ensure they meet specific quality and performance criteria. Compliance with these standards provides assurance of the strip's suitability for wire rope production. It is important to note that these specifications can vary depending on the specific requirements of the wire rope applications, such as load capacity, working environment, and safety regulations. Therefore, it is essential to consult the relevant industry standards and the wire rope manufacturer's guidelines for specific specifications and recommendations.

- Q:What is the typical hardness range for steel strips?

- The hardness range of steel strips can differ depending on the specific steel type and its intended use. Generally, steel strips have a hardness range of 20 to 60 on the Rockwell C scale (HRC). This range guarantees the steel strip's strength and durability for industrial purposes like automotive components, construction materials, cutting tools, and machinery parts. It's worth mentioning that the hardness range can be further tailored to meet the specific needs of the final product.

- Q:What are the main uses of steel strips?

- Steel strips have a wide range of applications. Some of the main uses include manufacturing automotive components, construction materials, household appliances, machinery parts, packaging materials, and electrical equipment.

- Q:What are the environmental considerations associated with steel strip production?

- Several environmental considerations need to be taken into account when it comes to steel strip production. Firstly, the extraction of iron ore, which is the main raw material for steel production, can cause habitat destruction and loss of biodiversity. Mining activities can disrupt ecosystems and contribute to deforestation and soil erosion. The process of converting iron ore into steel requires a significant amount of energy and results in the emission of substantial greenhouse gases, particularly carbon dioxide (CO2). Steel production is one of the leading sources of CO2 emissions in the industrial sector worldwide. These emissions contribute to climate change and worsen environmental challenges. In addition to CO2 emissions, steel production can release other air pollutants, such as sulfur dioxide (SO2) and nitrogen oxides (NOx). These pollutants can cause air pollution and have negative effects on both human health and the environment. They can contribute to the formation of smog, acid rain, and respiratory problems. Water consumption and water pollution are also associated with steel strip production. The production process requires a large amount of water for cooling and cleaning purposes, which can strain local water sources, especially in areas with limited water availability. Moreover, the discharge of wastewater from the production process can contain contaminants like heavy metals and chemicals, which can pollute water bodies and harm aquatic life. Waste management is another crucial consideration. Steel production generates various types of waste, including slag, dust, and sludge. Proper management and disposal of these wastes are essential to prevent environmental contamination and minimize the impact on surrounding ecosystems. To address these environmental considerations, the steel industry has been implementing various strategies. These include enhancing energy efficiency, adopting cleaner technologies, and investing in renewable energy sources to reduce greenhouse gas emissions. Recycling steel is also vital in reducing the environmental impact, as it helps conserve natural resources, reduce energy consumption, and minimize waste generation. Furthermore, the implementation of stringent environmental regulations and standards plays a significant role in promoting sustainable steel production. Governments, industry stakeholders, and consumers all have a responsibility to support and demand environmentally responsible practices in the steel industry. With continuous efforts and advancements, it is possible to minimize the environmental footprint of steel strip production and move towards a more sustainable and eco-friendly steel industry.

- Q:Can steel strips be coated with protective coatings?

- Yes, steel strips can be coated with protective coatings. Coating steel strips with protective coatings is a common practice in various industries to enhance their durability, resistance to corrosion, and overall performance. There are several types of protective coatings available for steel, including but not limited to, galvanized coatings, powder coatings, epoxy coatings, and paint coatings. Galvanized coatings, for example, involve applying a layer of zinc to the steel strip through a process known as hot-dip galvanizing. This coating provides excellent corrosion resistance and protects the steel from environmental factors such as moisture and chemicals. Powder coatings are another popular option for protecting steel strips. In this process, a dry powder is applied to the steel strip electrostatically, and then it is cured under heat to create a durable and tough coating. Powder coatings offer excellent adhesion and resistance to abrasion, impact, and chemicals. Epoxy coatings, on the other hand, are commonly used to protect steel strips in harsh environments. These coatings are highly resistant to chemicals, moisture, and extreme temperatures. They provide an additional layer of protection to the steel, preventing corrosion and extending its lifespan. Paint coatings are also widely used to protect steel strips. These coatings can be applied by various methods such as spraying, brushing, or dipping. Paint coatings offer flexibility in terms of color options and can provide a decorative finish in addition to protecting the steel strip from corrosion and other damaging factors. In conclusion, steel strips can indeed be coated with various protective coatings to enhance their performance and longevity. The choice of coating will depend on the specific requirements of the steel strip and the environment it will be exposed to.

- Q:What are the different thickness options for steel strips?

- The different thickness options for steel strips can vary depending on the specific application and industry requirements. However, common thickness options for steel strips range from as thin as 0.005 inches (0.13 mm) to as thick as 0.25 inches (6.35 mm) or more.

- Q:How are steel strips used in the manufacturing of storage racks?

- Storage racks commonly utilize steel strips for their durability and strength in the manufacturing process. These strips are typically molded into different shapes and sizes to serve as the framework and support structure of the rack. They fulfill various functions such as upright posts, horizontal beams, and cross braces, providing stability and load-bearing capacity. Steel strips are renowned for their high strength-to-weight ratio, making them an ideal option for storage racks that need to bear heavy loads. They are often crafted from robust steel alloys capable of withstanding substantial weight and pressure without bending or warping. Throughout the manufacturing process, steel strips are cut, shaped, and welded together to form the desired rack structure. They are frequently coated with protective finishes or paints to prevent corrosion and extend their lifespan. Additionally, galvanization can be applied to enhance resistance against rust and other forms of degradation. Once assembled, the steel strips create a strong and reliable framework that can support a wide range of items. These racks are commonly employed in warehouses, retail stores, and other industrial settings to facilitate storage and organization. By ensuring the rack can withstand the weight of stored items and remain stable, the steel strips reduce the risk of accidents or damage. In summary, steel strips are essential components in the manufacturing of storage racks as they provide the necessary strength and durability to support heavy loads. Their versatility and adaptability have made them a popular choice across various industries where efficient storage and organization are of utmost importance.

- Q:Can steel strips be used for stamping or forming?

- Yes, steel strips can be used for stamping or forming.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Zinc Coating Steel Building Roof Walls Steel Coil ASTM 615-009

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords