Stainless Steel Coil SS 201/304/316/304L/316L/309S/310S/430 stainless steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Coil Description

The surface brightness and flatness of no2B is better than no2D. then through a special

surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses.

2.Main Features of the Stainless Steel Coil

• Tensile strength: not less than 520

• Provides that non-proportional extension strength: not less than 205

• Elongation: not less than 35; 3 density: 7.98

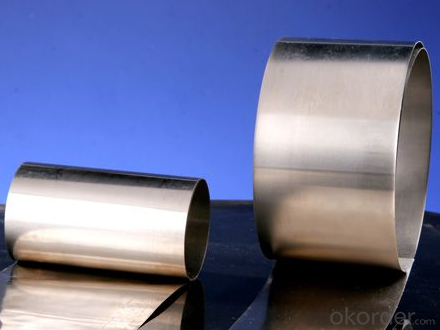

3. Stainless Steel Coil Images

4. Stainless Steel Coil Specification

| Grade: | 200series.300series. | Standard: | JIS,AISI,ASTM | Length: | as request |

| Thickness: | 0.3-3mm | Width: | 30-2000mm | Place of Origin: | Shanxi China (Mainland) |

| Brand Name: | CNBM | Model Number: | ss201/304/316/304L/316L/309S/310S/430 | Type: | Coil |

| Application: | hardware, foodstuff, manufacture, medic | Certification: | SGS | Item: | ss202/304/316/309s/310/410/420 stainless steel sheet |

| Packaging: | Export standard package or as your requirement | Delivery: | In 15 days | Stock: | Available |

5.FAQ of Stainless Steel Coil

①Who are you?

We are the manufacturer! We produce stainless steel products

with high quality & very competitive price!Please feel free to

contact us for more information!

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How about your company?

A world class manufacturer & supplier of castings forging in Stainless Steel Sheet,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q:How do steel strips contribute to reducing overall production costs in various applications?

- Steel strips contribute to reducing overall production costs in various applications in several ways. Firstly, steel strips are highly durable and have a long lifespan. This means that once installed in a specific application, they require minimal maintenance and replacement, resulting in lower costs over time. Unlike other materials that may wear out or break easily, steel strips can withstand harsh conditions and heavy loads, making them cost-effective in the long run. Secondly, steel strips are versatile and can be customized to meet specific requirements. This flexibility allows manufacturers to optimize the use of steel strips in various applications, reducing waste and minimizing the need for additional materials. By customizing the dimensions and specifications of steel strips, manufacturers can maximize their efficiency, leading to cost savings. Moreover, steel strips have excellent strength-to-weight ratio, meaning they are strong and lightweight at the same time. This characteristic makes them ideal for applications where weight reduction is crucial, such as automotive or aerospace industries. By using steel strips instead of heavier materials, manufacturers can reduce transportation costs and improve fuel efficiency, resulting in overall cost reduction. Furthermore, steel strips can be produced in large quantities at a relatively low cost. The manufacturing process for steel strips is highly efficient, allowing for mass production at a competitive price. This scalability makes steel strips a cost-effective choice for various applications, from construction to electrical appliances. Lastly, steel strips are recyclable, which further contributes to cost reduction. The ability to recycle steel strips not only helps to protect the environment but also provides manufacturers with a sustainable and cost-effective solution. By reusing and recycling steel strips, manufacturers can reduce the need for raw materials and minimize waste disposal costs. In conclusion, steel strips contribute to reducing overall production costs in various applications by offering durability, versatility, strength-to-weight ratio, scalability, and recyclability. These qualities make steel strips a cost-effective choice for manufacturers looking to optimize their production processes and minimize expenses.

- Q:Are steel strips used in the medical industry?

- Yes, steel strips are commonly used in the medical industry for various applications such as surgical instruments, medical implants, and diagnostic equipment.

- Q:How are steel strips used in the manufacturing of transmission towers?

- Steel strips are used in the manufacturing of transmission towers as they are shaped and welded together to form the structural components of the tower, providing strength, stability, and support for the transmission lines.

- Q:Are steel strips commonly used in the manufacturing of HVAC systems?

- Yes, steel strips are commonly used in the manufacturing of HVAC systems. They are often used for various components such as ductwork, coil casings, and support brackets due to their strength, durability, and versatility in HVAC applications.

- Q:What are the common surface defect inspection methods for steel strips?

- The common surface defect inspection methods for steel strips include visual inspection, magnetic particle inspection, ultrasonic testing, eddy current testing, and dye penetrant testing.

- Q:What are the common defects in steel strips?

- Some common defects in steel strips include surface defects such as scratches, pits, and scale formation, as well as edge defects like burrs and cracks. Other defects may include thickness variations, waviness, and non-uniformity in width.

- Q:Can steel strips be used in the production of electronics?

- Yes, steel strips can be used in the production of electronics. They are often used as a base material for circuit boards and as a structural component in electronic devices due to their strength, durability, and ability to dissipate heat effectively.

- Q:Are steel strips suitable for the production of hand tools?

- Yes, steel strips are suitable for the production of hand tools. Steel strips are strong and durable, making them ideal for creating tools that require strength and precision. Additionally, steel strips can be easily shaped and molded to create various hand tool designs, further enhancing their suitability for production.

- Q:What are the different coating options available for steel strips?

- Some of the different coating options available for steel strips include galvanized coatings, which provide protection against corrosion; organic coatings, such as paint or powder coatings, which offer aesthetic appeal and additional durability; and metallic coatings, such as zinc-nickel or aluminum coatings, which provide enhanced corrosion resistance and conductivity. Other options may include phosphate coatings for improved adhesion or specialty coatings for specific applications, such as lubrication or insulation.

- Q:How are steel strips used in the production of machinery?

- Due to their versatility and durability, steel strips find wide application in the production of machinery. These narrow bands of steel are utilized at various stages of machinery production. One of the primary uses of steel strips in machinery production lies in fabricating machine components. These strips can be cut, shaped, and formed into specific parts like gears, springs, brackets, and clamps. The high tensile strength and resistance to deformation of steel make it an ideal material for these critical components, ensuring their longevity and reliability in machinery operation. Moreover, steel strips are commonly employed in constructing conveyor systems and assembly lines. They serve as belt materials that transport materials or finished products within the machinery. The smooth and flat surface of steel strips allows for efficient movement and reduces friction, enabling the machinery to operate smoothly and consistently. Furthermore, steel strips with magnetic properties, such as electrical steel, are used in the production of electric motors and generators. These strips act as the core material, facilitating efficient and reliable generation and transmission of electrical energy. In addition to their mechanical and electrical properties, steel strips play a vital role in machinery production due to their corrosion resistance. Machinery components exposed to moisture, chemicals, or harsh environments often require protection against corrosion. Coating these components with a layer of corrosion-resistant steel strips significantly extends the machinery's lifespan, reducing maintenance and replacement costs. In summary, steel strips are essential in machinery production because of their versatility, durability, and numerous beneficial properties. Whether it is fabricating components, constructing conveyor systems, enhancing electrical performance, or preventing corrosion, steel strips contribute to the reliability and efficiency of machinery in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil SS 201/304/316/304L/316L/309S/310S/430 stainless steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords