All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

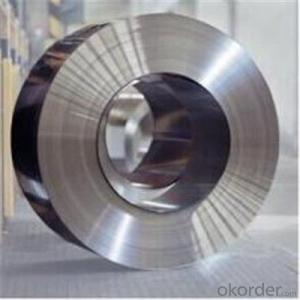

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of steel strips in the manufacturing of firearms?

Steel strips play a crucial role in the manufacturing of firearms as they are typically used to form the main structural components of the weapon, such as the barrel, receiver, and various other parts. These strips are often shaped, machined, and heat-treated to provide the necessary strength, durability, and precision required for the firearm to function reliably and safely.

How do steel strips contribute to the manufacture of power transmission components?

Steel strips are used in the manufacture of power transmission components because they provide strength, durability, and flexibility. These strips can be easily formed into various shapes and sizes, allowing for the production of precise and efficient components such as gears, shafts, and couplings. Additionally, steel strips have excellent conductivity properties, making them ideal for transmitting electrical power through the components.

What are the specifications for steel strips used in the production of energy-efficient components for the automotive industry?

The specifications for steel strips used in the production of energy-efficient components for the automotive industry may vary depending on the specific component and its intended application. However, some common specifications for these steel strips include high strength-to-weight ratio, excellent formability, good weldability, and corrosion resistance. Additionally, these strips may need to meet specific mechanical properties, such as specific tensile strength, yield strength, and elongation. It is important to consult with automotive industry standards and specific component requirements for precise specifications.

How does the thickness of steel strips affect their applications?

The thickness of steel strips plays a crucial role in determining their applications. Thicker steel strips are generally preferred for applications that require higher strength and durability, such as structural components in buildings, bridges, and heavy machinery. Thinner steel strips, on the other hand, are more suitable for applications that demand flexibility and versatility, such as automotive panels, appliances, and packaging materials. The thickness of steel strips directly impacts their ability to withstand stress, load-bearing capacity, and resistance to deformation, making it a critical factor in determining their specific applications.

Wholesale Steel Strips from supplier in Gabon

Whether you are in need of steel strips for construction, manufacturing, or any other application, we have you covered. Our team of experts will assist you in selecting the right products based on your specific requirements and budget.

In addition to supplying high-quality steel strips, we also offer competitive pricing, flexible payment terms, and efficient logistics services to ensure a smooth and hassle-free procurement process. We understand the importance of timely delivery and will work closely with you to meet your project deadlines.

Furthermore, our technical support team is always available to provide guidance and assistance with any technical queries or challenges you may encounter. We believe in building long-term partnerships with our clients and strive to exceed their expectations in terms of product quality, service, and support.

With our strong presence in Gabon and access to a wide network of suppliers and manufacturers, we are confident in our ability to meet your steel strip requirements efficiently and effectively. Contact us today for a reliable and comprehensive solution for all your steel strip needs in Gabon.

In addition to supplying high-quality steel strips, we also offer competitive pricing, flexible payment terms, and efficient logistics services to ensure a smooth and hassle-free procurement process. We understand the importance of timely delivery and will work closely with you to meet your project deadlines.

Furthermore, our technical support team is always available to provide guidance and assistance with any technical queries or challenges you may encounter. We believe in building long-term partnerships with our clients and strive to exceed their expectations in terms of product quality, service, and support.

With our strong presence in Gabon and access to a wide network of suppliers and manufacturers, we are confident in our ability to meet your steel strip requirements efficiently and effectively. Contact us today for a reliable and comprehensive solution for all your steel strip needs in Gabon.