All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

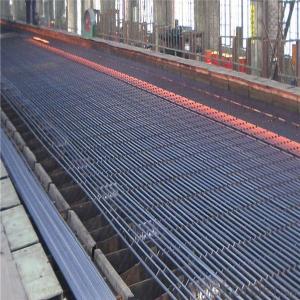

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the best practices for using steel rebars in the renovation and restoration of heritage buildings?

When using steel rebars in the renovation and restoration of heritage buildings, some best practices include conducting a thorough assessment of the building's structural integrity, consulting with preservation experts, and adhering to applicable heritage conservation guidelines. It is important to carefully select the appropriate type and size of rebars, ensuring compatibility with the existing structure. Additionally, proper installation techniques and corrosion protection measures should be employed to ensure the rebars' longevity and minimize any potential damage to the heritage building.

How do you calculate the minimum number of steel rebars required in a column?

To calculate the minimum number of steel rebars required in a column, you need to consider the column's dimensions, the required strength, and the local building codes or standards. The minimum number of rebars can be determined by analyzing the column's cross-sectional area and applying the specified steel reinforcement ratio, which is typically a percentage of the concrete's cross-sectional area. This ratio accounts for the column's load-bearing capacity and ensures it can withstand the expected forces.

What is the impact of concrete shrinkage on steel-reinforced structures, and how can it be mitigated?

Concrete shrinkage can have a significant impact on steel-reinforced structures. As concrete undergoes the drying and curing process, it tends to shrink, which can lead to cracks and deformation in the structure. These cracks not only compromise the aesthetics but also decrease the structural integrity and durability of the steel reinforcement.

To mitigate the impact of concrete shrinkage on steel-reinforced structures, several measures can be taken. Firstly, using low shrinkage concrete mixes with appropriate admixtures can minimize the overall shrinkage. Additionally, incorporating steel reinforcement with higher yield strength and appropriate spacing can help distribute the stresses caused by shrinkage, reducing the risk of cracking.

Moreover, proper curing techniques such as moist curing or the use of curing compounds can reduce shrinkage by maintaining adequate moisture content in the concrete during the initial stages. Furthermore, implementing joint systems and control joints can allow controlled cracking at predetermined locations, relieving the stress caused by shrinkage.

Regular inspection and maintenance of the structure are also crucial to identify and repair any shrinkage-related issues promptly. By adopting these mitigation strategies, the impact of concrete shrinkage on steel-reinforced structures can be minimized, ensuring their long-term stability and performance.

How do you prevent steel rebar congestion in concrete structures?

To prevent steel rebar congestion in concrete structures, proper design and planning are essential. This can be achieved by using detailed structural drawings and specifications that accurately determine the required reinforcement quantities and spacing. Adequate spacing between rebars should be maintained to ensure proper concrete flow and consolidation. Additionally, using larger diameter rebars or alternative reinforcement materials can reduce the overall number of bars needed, minimizing congestion. Regular inspections during construction can help identify and rectify any potential congestion issues before concrete placement.

Wholesale Steel Rebars from supplier in Gabon

With a strong focus on quality, reliability, and customer satisfaction, we are committed to meeting the specific requirements of our clients in Gabon. Our Steel Rebars are manufactured using the highest industry standards and undergo rigorous quality control processes to ensure superior strength and durability.

We offer a wide range of Steel Rebars products, including standard rebar, epoxy-coated rebar, stainless steel rebar, and more, catering to various construction needs. Our team of experienced professionals is dedicated to providing personalized services to help you choose the right Steel Rebars for your projects and ensure timely delivery.

Moreover, our technical support team is available to assist you throughout the entire procurement process, from product selection to installation guidance. We understand the unique challenges and regulations of the Gabon market, and we can provide expert advice to help you make well-informed decisions.

At our company, we believe in building long-term partnerships with our clients based on trust, reliability, and mutual success. We strive to exceed customer expectations by delivering exceptional products and services that meet international quality standards.

Contact us today to discuss your Steel Rebars requirements in Gabon, and let us provide you with the best solutions for your construction projects.

We offer a wide range of Steel Rebars products, including standard rebar, epoxy-coated rebar, stainless steel rebar, and more, catering to various construction needs. Our team of experienced professionals is dedicated to providing personalized services to help you choose the right Steel Rebars for your projects and ensure timely delivery.

Moreover, our technical support team is available to assist you throughout the entire procurement process, from product selection to installation guidance. We understand the unique challenges and regulations of the Gabon market, and we can provide expert advice to help you make well-informed decisions.

At our company, we believe in building long-term partnerships with our clients based on trust, reliability, and mutual success. We strive to exceed customer expectations by delivering exceptional products and services that meet international quality standards.

Contact us today to discuss your Steel Rebars requirements in Gabon, and let us provide you with the best solutions for your construction projects.