WPC Wood Plastic Composite Natural Colour Slip Resistance to Water Rot

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of WPC Decking :

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

Description Main Features of the WPC Decking:

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

indoor wpc flooring

deck wpc solid

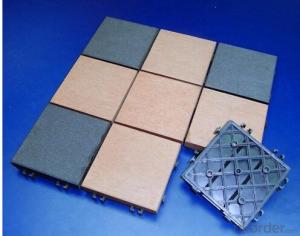

WPC Decking Images:

WPC Decking Specicication:

FAQ of WPC Decking :

1> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

2> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

3> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

4> How to buy and concerned terms?

*MOQ – 300m2 per item

*Lead time—2 weeks

*Departure port—Shanghai

*Package-- PE film, carton box or 2pcs.bundle, treated pallet

5> Certificates and Quality guarantee

*Certificates – CE&ISO 9001 complied

*Warranty—10 years

*Quality guarantee—test report for each order under the strict management system.

6> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

- Q:Strengthen the composite floor brand which? Recommended which?

- The three brands of Chinese composite wood flooring, have launched the E0-class environmental protection standards of the product, while the blessing and other brands of flooring also launched E0 floor, the price difference is not great, the elephant elephant Also launched the Photocatalyst technology of the floor, this floor has a role in the treatment of air, air can be harmful gases into carbon dioxide and water, I think this floor is better, of course, other brands have this technology, It is possible to compare the floor of the substrate is a green substrate or a white substrate, the white substrate of the better floor of the shop is to cut the light and the odds of the end with the use of plastic, is the keel, or lock Buckle type, and if the home is warm to see if it is not resistant to heat, there is no thermal slot.

- Q:Trying to redo the basement. Do I need to lay some type of subfloor or can I lay the engineered flooring directly onto the concrete?

- Normally, you need a moisture barrier under the flooring. This can be roofing felt or the special type made for flooring.

- Q:Can you strengthen the composite floor to make essential oils?

- Strengthen the floor does not need to play essential oils, do not need to play floor wax. Solid wood flooring and parquet are required. Strengthen the floor is usually to do the maintenance work. Usually to do the floor surface cleaning, timely cleaning of dust, wipe stains. Also, pay attention to the ventilation of the wood floor, can not be too tide or dry. Below the wooden floor maintenance of the two small methods, you can try, the effect is good. 1) When wiping the floor, pour the expired milk into the washbasin and add twice the water to dilute it. And then wiped the wipes wipe dry, you can wipe the floor. If the number of expired milk is more, you can rub with milk once a week. 2) Taomi Shui can also maintain the wood floor. Taomi water contains crude fiber, potassium and starch, after one or two rinse of Taomi Shui was weak acid, with detergency, you can also clean the wood floor.

- Q:How long will it change? The quality of those brands on the market is so durable? More

- Wood flooring is divided into solid wood flooring, wood composite wood flooring and laminate flooring. Under normal circumstances, these three kinds of wood floor life of not less than 15 years, like the foyer, the living room of the individual parts of the wear and tear will be bigger, such as sand and coffee table around, bathroom and kitchen door, will affect the wood floor life and beauty. In the wood flooring industry, the thickness of the wood floor is often very critical, it can roughly determine the life of wood flooring. The thicker the thickness of the wood floor, the longer the life of the wood floor. Solid wood flooring thickness is generally divided into 12 mm and 15 mm, wood flooring after the more that the higher the cost of solid wood flooring, the more expensive, but the relative use of the better, feet more comfortable. Of course, inside the solid wood composite floor thickness, in fact, mostly refers to the solid wood flooring surface of the precious wood layer.

- Q:Solid wood flooring multi-layer solid wood composite floor to strengthen the difference between the composite wood floor What is the difference between the few? Thank you!

- Solid wood flooring (belong to the luxury goods) Washed off the cake after the water shortage of leather palace Gong: the original ecological products, texture is good, long service life. The But the stability is not high, the wood is susceptible to climate impact Dry and cold shrink multi-layer solid wood flooring: solid wood panels, core board and backplane by other logs. The wood cut into pieces after the vertical and horizontal stacking to restrain the wood dry and cold shrinkage of the curvature, stability and strength is relatively independent of solid wood, the so-called new solid wood! But the use of life is not single solid wood long (no solid wood so easy to deformation) to strengthen the composite wood flooring (economic and durable): texture is not solid wood flooring. Is made of wood broken wood made of fiber, made by hot pressing made of substrate with decorative paper and wear-resistant layer made of wear-resistant surface, so the paint is not so easy to damage the solid wood! Very wear-resistant, easy to deformation, surface damage and so on. The The Patterns are all computer graphics, so there is no problem such as solid wood color

- Q:Will the solid wood flooring front line brand which

- Solid wood flooring is developed from the solid wood flooring, with a solid wood flooring comfortable foot feel and strengthen the characteristics of wear and tear on the floor, with the use of OKorder bile high sense of wood for picking pulp, the solid wood composite floor is divided into table Plate and substrate, the use of solid wood flooring, the price relative to the solid wood floor is more affordable. Currently on the market, many brands of solid wood flooring, the main are: Europe to send the floor, Del floor, the elephant floor, life home, nature, these brands have more than 10 years of experience, product quality and after sale Aspects are guaranteed, is a trusted brand.

- Q:My home is used: Montblanc Teng map of the floor, renovation is less than two months began to drums, there are more than a dozen, looking for after-sales service providers, he said that is engaged in the infiltration of lying lie, Run by water. I do not understand, we engage in cleaning are the first wiping the damp, and then wring dry, if you do so on the drum package, how to do after cleaning? Is there a problem with the quality of the floor? Please enlighten the Supreme more

- There is no way to repair the floor from the tide, only for the change

- Q:Such as title

- With a rag dipped in hot water can be removed more rub, rub clean and then wash the towel.

- Q:Why is it better to use solid wood flooring?

- Why is it better to use solid wood flooring?

- Q:Advantages and disadvantages of composite flooring?

- Advantages: replacement, laying, easy to simple, wearable. Disadvantages: fear of water, afraid of moisture. Personally think that more affordable.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WPC Wood Plastic Composite Natural Colour Slip Resistance to Water Rot

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products