Wooden Pattern Roll Coated Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Wooden Pattern Roll Coated Aluminum Coil

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Wooden Pattern Roll Coated Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Pattern Roll Coated Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

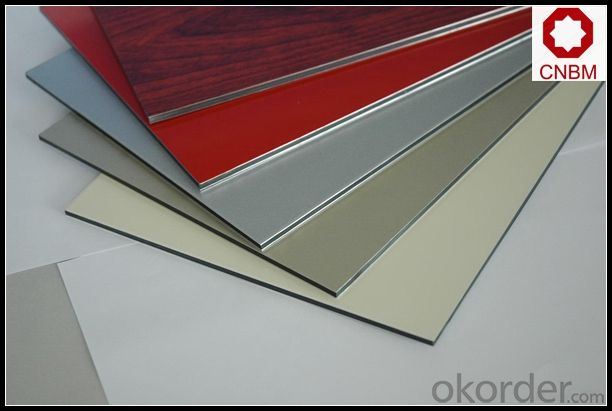

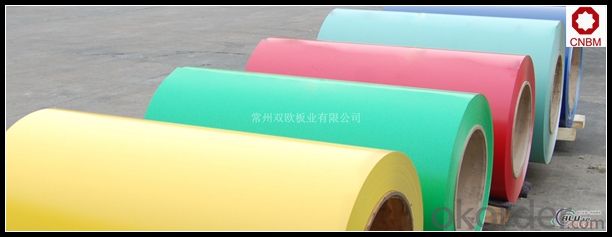

5. Image of Wooden Pattern Roll Coated Aluminum Coil

6. Package and shipping of Wooden Pattern Roll Coated Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:How are aluminum coils processed for specific applications?

- Aluminum coils undergo a series of processes to tailor them for specific applications. The first step is the selection of high-quality aluminum alloy, which determines the coil's properties. Once the alloy is chosen, it is melted and cast into large ingots. After cooling, the ingots are rolled between heavy rollers to reduce their thickness and form long, continuous aluminum coils. Next, the coils are subjected to various surface treatments to enhance their performance and appearance. One common treatment is cleaning, which removes any impurities or contaminants from the coil's surface. This is typically done through chemical or mechanical methods. Another treatment is chemically etching the surface to create a specific texture or pattern, which can improve adhesion or aesthetics. To further enhance the coil's properties, it may undergo processes like heat treatment or annealing. Heat treatment involves heating the coil to a specific temperature and then rapidly cooling it to modify its mechanical or physical properties. Annealing, on the other hand, involves heating the coil to a predetermined temperature and then slowly cooling it to relieve internal stresses and improve its ductility. Coils destined for specific applications may also undergo additional processes. For instance, if the coil is intended for use in the automotive industry, it may be subjected to lubrication or coating processes to reduce friction or improve corrosion resistance. If it is meant for electrical applications, it might undergo surface treatments to enhance its conductivity or insulation properties. Finally, the coils are usually cut into desired lengths and packaged for transportation. This can be done through various methods like slitting, shearing, or sawing, depending on the application and customer requirements. Overall, the processing of aluminum coils for specific applications involves a combination of casting, rolling, surface treatment, heat treatment, and additional processes to enhance their performance, appearance, and suitability for their intended use.

- Q:My boyfriend sweats a lot and uses Mitchlum deodorant, a lot of it, under his armpits and waits til it dries to stop the sweating. I heard aluminium was bad for you, but he says natural deodorants don't work as well. What do you think?

- Aluminium is bad for you and too much aluminium can cause Alzheimer's disease and other problems. External deodorants are displaced by your perspiration and don't last long. Liquid chlorophyll is an internal deodorant that deodorises your body odours and perspiration odours before they come out of your pores. A table spoon of high strength liquid chlorophyll every day is all you need. Liquid chlorophyll also has a cooling effect so you perspire a bit less. You can find further information in a search for liquid chlorophyll + deodorant.

- Q:Are aluminum coils resistant to vibration?

- Aluminum coils, typically, exhibit resistance to vibrations. Being lightweight and flexible, aluminum possesses the capability to absorb vibrations and alleviate their effects. Moreover, aluminum coils find extensive usage in crucial areas where vibration resistance holds significance, such as HVAC systems, automotive components, and electrical transformers. The commendable strength-to-weight ratio of aluminum further contributes to its capacity to endure vibrations without distortion or fracturing. Nevertheless, the precise degree of vibration resistance could vary depending on the distinctive design and construction of the aluminum coil.

- Q:Are aluminum coils suitable for heat sinks?

- Yes, aluminum coils are suitable for heat sinks. Aluminum is a lightweight, highly conductive material that efficiently transfers heat away from electronic components. Its excellent thermal conductivity and corrosion resistance make it a popular choice for heat sink applications.

- Q:Can aluminum coils be used in aerospace heat exchangers?

- Yes, aluminum coils can be used in aerospace heat exchangers. Aluminum is widely used in aerospace applications due to its lightweight and excellent heat transfer properties. It offers good corrosion resistance, high thermal conductivity, and is cost-effective, making it a suitable material for heat exchangers used in aircraft and other aerospace systems.

- Q:Can aluminum coils be used in roofing or cladding systems?

- Yes, aluminum coils can be used in roofing or cladding systems. Aluminum is a lightweight and corrosion-resistant material, making it suitable for these applications. It offers durability, flexibility, and ease of installation, making it a popular choice in the construction industry.

- Q:What are the different packaging options for aluminum coils?

- There are several different packaging options for aluminum coils, including wooden crates, cardboard boxes, shrink wrap, and stretch wrap. These packaging options help protect the coils from moisture, dust, and physical damage during transportation and storage. Additionally, some suppliers may offer customized packaging solutions to meet specific requirements and ensure the safe delivery of aluminum coils.

- Q:How are aluminum coils used in the production of food processing equipment?

- Aluminum coils are widely used in the production of food processing equipment due to their desirable characteristics and benefits. These coils are typically made from high-quality aluminum alloy, which offers excellent heat conductivity, corrosion resistance, and durability. One primary application of aluminum coils in the food processing industry is in the construction of heat exchangers. These heat exchangers are essential components of various food processing equipment, such as ovens, fryers, and refrigeration systems. The aluminum coils within the heat exchangers facilitate the transfer of heat between different mediums, ensuring efficient and precise temperature control during food processing. Another important use of aluminum coils is in the manufacturing of evaporator coils. These coils are integral to refrigeration systems used in commercial food processing. The evaporator coils, made from aluminum, aid in the cooling process by absorbing heat from the surrounding environment and allowing refrigerants to evaporate, thereby maintaining low temperatures within the equipment. Additionally, aluminum coils find application in the construction of food storage and transportation equipment, such as refrigerated trucks and containers. Aluminum's lightweight nature contributes to fuel efficiency and enables easier transportation of food products while maintaining their quality and freshness. Furthermore, aluminum coils are valued for their hygienic properties and ease of cleaning, making them ideal for food processing equipment. Aluminum surfaces can be easily sanitized, ensuring a high level of cleanliness and preventing contamination during food production. Overall, aluminum coils play a crucial role in the production of food processing equipment by providing excellent heat transfer, corrosion resistance, durability, and hygienic qualities. Their usage helps ensure efficient food processing operations, optimal temperature control, and the maintenance of food quality and safety standards.

- Q:Can aluminum coils be used in the manufacturing of medical devices?

- Yes, aluminum coils can be used in the manufacturing of medical devices. Aluminum is a versatile material that offers several advantages for medical device manufacturing. It is lightweight, corrosion-resistant, and has good thermal conductivity. These properties make aluminum coils suitable for various medical applications such as medical imaging equipment, surgical instruments, and prosthetics. Medical imaging devices, such as MRI and CT scanners, often use aluminum coils to transmit and receive electromagnetic signals. Aluminum's electrical conductivity allows for efficient signal transmission, enhancing the accuracy and quality of medical imaging. Additionally, aluminum's lightweight nature makes it easier to handle and maneuver during medical procedures. Aluminum coils are also used in the manufacturing of surgical instruments. These instruments require materials that are sterilizable, durable, and have high strength. Aluminum meets these requirements, as it can be easily sterilized using various methods, including steam, ethylene oxide, or gamma irradiation. Its durability ensures that the instruments can withstand repeated sterilization cycles without degradation, and its high strength ensures the instruments can withstand the forces applied during surgical procedures. Moreover, aluminum can be employed in the production of prosthetics, such as artificial limbs. Aluminum's lightweight nature makes it an ideal material for creating prosthetic devices that are comfortable for patients to wear and move around with. Additionally, its corrosion-resistant properties make it suitable for long-term use, as it can withstand exposure to body fluids and environmental factors. Overall, aluminum coils can indeed be used in the manufacturing of medical devices. Their lightweight, corrosion-resistant, and electrically conductive properties make them a valuable material for medical applications, contributing to the development of advanced and reliable medical devices.

- Q:What is the maximum temperature aluminum coils can withstand?

- The maximum temperature that aluminum coils can withstand depends on several factors, including the specific alloy of aluminum and the intended application of the coils. Generally, aluminum has a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit). However, aluminum coils used in various industries such as HVAC (heating, ventilation, and air conditioning) systems and electrical appliances are typically designed to operate within a temperature range of -30 to 150 degrees Celsius (-22 to 302 degrees Fahrenheit). These temperature limits ensure that the aluminum coils maintain their structural integrity and do not experience any significant degradation or damage. It is important to consult the manufacturer's specifications or guidelines for the specific aluminum coils in question to determine their maximum temperature tolerance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wooden Pattern Roll Coated Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords