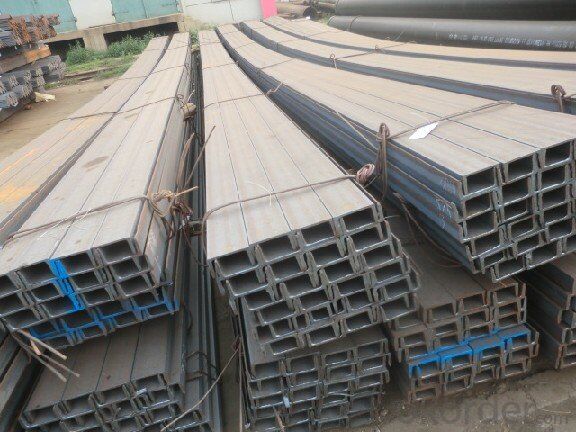

Wholesale 2015 High Quality Structure Steel U Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

high quality Hot Rolled Steel U Beam at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm |

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Product Applications:

Hot Rolled Steel U-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel U-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

- Q:Can steel channels be used in earthquake-prone areas?

- Provided that they are designed and installed correctly, steel channels can be utilized in earthquake-prone regions. Steel, being a robust and durable material, is suitable for withstanding seismic forces. However, several factors must be considered when implementing steel channels in such areas. First and foremost, the design of the steel channels must adhere to the applicable seismic codes and regulations. These codes provide guidelines that outline the minimum requirements for structural integrity and seismic resistance. Engineers must take into account factors like the seismic activity of the region, soil conditions, and anticipated ground movements to ensure that the steel channels can endure the forces generated during an earthquake. Secondly, proper installation is of utmost importance to guarantee the effectiveness of steel channels in earthquake-prone areas. The channels must be securely anchored to the foundation and connected to other structural components to form a robust system. It is necessary to employ welding or bolting methods to ensure strong connections and prevent any potential points of failure. Furthermore, regular inspections and maintenance are essential to uphold the ongoing structural integrity of the steel channels. This entails checking for any signs of deterioration, damage, or corrosion that may jeopardize their performance during an earthquake. Any identified issues should be promptly addressed to maintain the channels' effectiveness in seismic events. It is also important to note that while steel channels can provide structural strength, it is imperative to consider other factors holistically, such as building design, foundation systems, and overall construction, to ensure the safety of buildings in earthquake-prone areas. In conclusion, steel channels can indeed be utilized in earthquake-prone areas if they are designed, installed, and maintained correctly. Adhering to seismic codes, ensuring proper installation, conducting regular inspections, and considering other building factors are all crucial in guaranteeing the structural integrity and safety of buildings in these regions.

- Q:Can steel channels be used for framing walls?

- Indeed, framing walls is possible with the utilization of steel channels. These steel channels, alternatively referred to as C-channels or U-channels, find frequent usage within the construction industry for framing walls, ceilings, and floors. The strength, durability, and resistance to warping that steel channels possess make them an optimal selection for structural framing purposes. Moreover, steel channels contribute stability and support to the walls, aiding in the even distribution of the load and guaranteeing the building's structural integrity. Furthermore, the versatility of steel channels allows for effortless customization and cutting to the desired length, rendering them suitable for diverse wall framing applications.

- Q:What are the different types of accessories used with steel channels in construction?

- There are several different types of accessories used with steel channels in construction, including brackets, connectors, clamps, and fasteners. These accessories are used to secure the steel channels in place, connect them to other structural components, provide additional support, and enhance their overall functionality.

- Q:What are the different types of coatings available for steel channels?

- There are several different types of coatings available for steel channels, each offering unique benefits and properties. Some of the most common types of coatings include: 1. Galvanized Coating: This is one of the most popular and widely used coatings for steel channels. Galvanizing involves applying a layer of zinc to the surface of the steel, providing excellent corrosion resistance. This coating is durable, long-lasting, and protects the steel from rusting and other environmental damage. 2. Powder Coating: Powder coating is a dry finishing process where a powdered polymer is applied to the steel channel and then heated to form a protective layer. This type of coating offers excellent durability, chip resistance, and aesthetic appeal. Powder coating can be customized in various colors, making it ideal for decorative applications. 3. Epoxy Coating: Epoxy coatings are highly resistant to chemicals, moisture, and abrasion. They are commonly used in industrial and marine applications where the steel channels are exposed to harsh environments. Epoxy coatings provide excellent protection against corrosion and can also improve the overall appearance of the steel. 4. Paint Coating: Paint coatings are widely used on steel channels for both functional and decorative purposes. They provide a smooth and aesthetically pleasing finish while also offering some level of corrosion protection. Depending on the requirements, different types of paints, such as acrylic, enamel, or urethane, can be used for coating steel channels. 5. Anodizing: Anodizing is a process that involves creating an oxide layer on the surface of the steel channel. This coating provides enhanced corrosion resistance and can also improve the durability of the steel. Anodized coatings are commonly used in architectural applications where the steel channels are exposed to outdoor elements. It is important to consider the specific requirements of the steel channel and the intended application when choosing the appropriate coating. Factors such as environmental conditions, desired lifespan, and aesthetics should all be taken into account to select the most suitable coating for steel channels.

- Q:Can steel channels be used in water treatment plants?

- Indeed, water treatment plants can make use of steel channels. The utilization of steel in water treatment plants is widespread owing to its resilience, robustness, and resistance to corrosion. Steel channels can serve multiple functions such as equipment support, walkway creation, and provision of structural support for pipelines and conduits. Nevertheless, it is crucial to take into account the precise requirements and conditions of the water treatment plant, including the type of water being treated and any potential chemical or environmental factors that could impact the steel channels. Applying a suitable coating or protection may be necessary to prevent corrosion and ensure the prolonged lifespan of the steel channels in the water treatment plant setting.

- Q:Can steel channels be used for roof structures?

- Indeed, roof structures can utilize steel channels. Construction frequently incorporates steel channels due to their robustness and endurance. They offer support for the structure and can function as purlins or rafters within roof systems. Steel channels possess the capability to endure substantial burdens and contribute stability to the entire framework. Furthermore, their fabrication and installation are hassle-free, rendering them a favored option for roof construction. Moreover, steel channels exhibit resistance to fire, corrosion, and pests, establishing them as a dependable and enduring choice for roof structures.

- Q:What are the precautions for handling and storing steel channels?

- When handling and storing steel channels, it is important to take certain precautions to ensure safety and prevent damage. Some of the precautions include using appropriate lifting equipment and techniques to avoid injuries, wearing personal protective equipment such as gloves and safety boots, and inspecting the channels for any defects or damage before handling them. Additionally, steel channels should be stored in a dry and well-ventilated area to prevent corrosion and damage. It is also important to stack the channels properly, ensuring that they are supported evenly to avoid any bending or warping.

- Q:Are steel channels suitable for the power generation manufacturing industry?

- Yes, steel channels are suitable for the power generation manufacturing industry. Steel channels offer excellent strength and durability, making them ideal for supporting heavy equipment and structures in power plants. They can be customized to meet specific requirements and are resistant to corrosion, which is crucial in power generation facilities where exposure to moisture and chemicals is common. Additionally, steel channels have excellent thermal conductivity, ensuring efficient heat transfer in power generation processes.

- Q:Can steel channels be galvanized or coated?

- Yes, steel channels can be galvanized or coated. Galvanizing is a process where a layer of zinc is applied to the surface of the steel channel to protect it from corrosion. This process involves dipping the steel channel into a bath of molten zinc or by applying a zinc coating using other methods such as electroplating or spraying. The zinc coating provides a barrier between the steel and the surrounding environment, preventing the steel from rusting. Coating steel channels is another option to protect them from corrosion. There are various types of coatings available, such as epoxy, polyurethane, or powder coatings, which can be applied to the surface of the steel channel. These coatings create a protective layer that shields the steel from moisture, chemicals, and other corrosive elements. Both galvanizing and coating steel channels enhance their durability and extend their lifespan. The choice between galvanizing and coating depends on factors such as the intended application, the environmental conditions in which the steel channel will be used, and the desired aesthetic appearance.

- Q:Which way is it better to weld the iron channel and galvanized steel channel in the house?

- Of course, galvanized well

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wholesale 2015 High Quality Structure Steel U Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords