Waterproof Non-woven Aramid Fabric with PTFE Film/Moisture Barrier Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

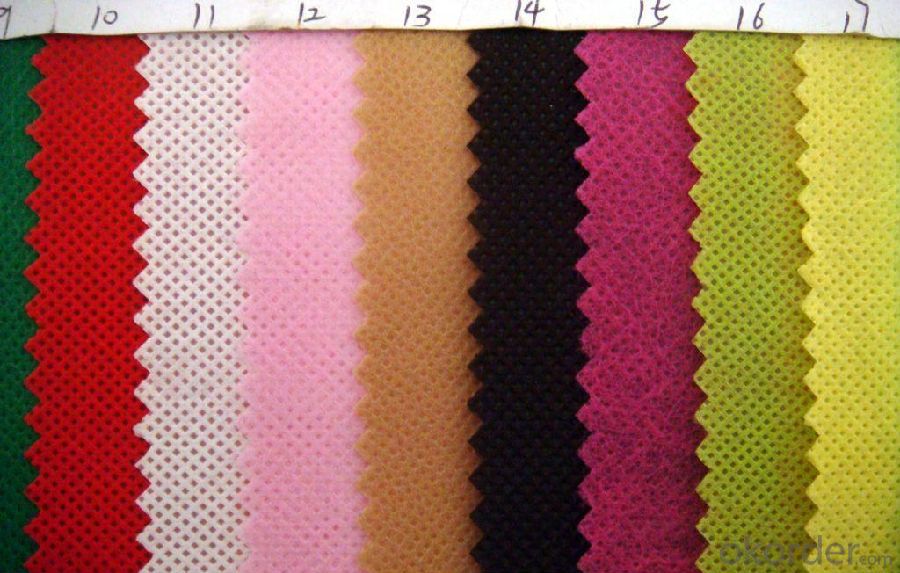

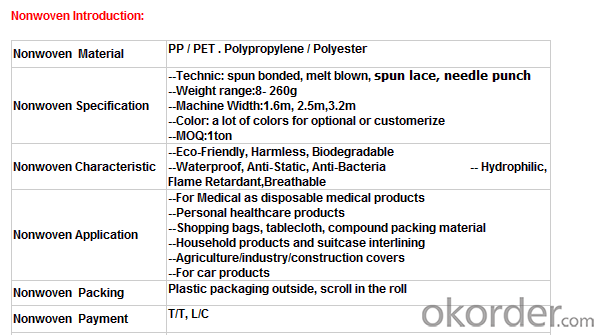

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q:What are the test tests for the color fastness of textiles?

- 13, resistant to non-chlorine color fastness 14, resistance to chlorine color fastness 15, acid color fastness 16, alkali color fastness 17, water-resistant color fastness 18, resistance to organic solvent friction color fastness

- Q:What are the products produced by the textile mill?

- From the ingredients that have: cotton, wool, silk, linen and chemical fiber, man-made fibers (viscose fiber).

- Q:The meaning of the following terms in the textile industry: fabric, processing number, genuine number.

- Jeans shrinkage is generally 15% to 40%. Look at the thickness of the fabric, and is not elastic, there are scrub, yeast, wash, rinse, rancid wash, and so on, different washing water has different washing steps, procedures

- Q:"Textile color standard system"

- Color fastness refers to the resistance of the color of the textile to various effects during processing and use. The fastness rating was determined according to the discoloration of the sample and the staining of the unstained fabric. Textile color fastness test is a textile internal quality testing in a routine testing project

- Q:Development of Textile Fibers.

- From the international environment, the international market is still a large expansion of space and opportunities. With the end of 2007, China and the EU textile limit expires, the end of 2008 the end of the Sino-US textile quota limit, the Chinese textile quota era is approaching, accounting for more than 60% of the global textile market share of the region fully open, will bring to China's textile trade Great opportunity.

- Q:China is now optimistic about which one of the textile industry

- Advanced geotextile complete sets of production technology and industrial wide high-strength technology-based geotextile, geogrid, waterproof membrane and other high-grade multi-functional geotextile composite materials production and application.

- Q:What kind of fiber can be used as textile fiber

- The main chemical composition of animal fiber is protein, it is also known as protein fiber. 2, chemical fiber, chemical fiber is processed by chemical processing and fiber. Can be divided into man-made fibers (regenerated fiber), synthetic fibers and inorganic fibers. Artificial fiber is also called regenerated fiber. The man-made fiber is made of natural fiber or protein fiber, such as wood, sugar cane, reed, soybean protein fiber and other fiber raw materials that lose the value of textile processing.

- Q:Textile finishing TPU, TPEF film. What's the difference?

- Hardness range: by changing the TPU reaction components of the ratio, you can get different hardness of the product, and with the increase in hardness, the product still maintain good flexibility and wear resistance.

- Q:How to grow in the textile industry and have their own customers

- First, the processing cycle of the process, which relates to your order delivery. Second, the process design, which relates to the use of your raw materials.

- Q:What is the earliest textile raw material?

- The ancient Roman Empire was first through the "Silk Road" on the spread of silk, said China as "silk country"

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof Non-woven Aramid Fabric with PTFE Film/Moisture Barrier Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products