Water Structure Germany Standard PPR Male Thread Coupling in 2017

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview:

1.It is used in industrial fields,agriculture and irrigation.

2.Beauty appearance.

3.Thermal insulation and energy saving.

4.Easy installation

5.excellent heat resistance and pressure resistance

6.affordable price

Product Applications:

1.Distribution for cool and hot water

2.Duct for drinkable water system

3.Pipes for kinds of high-temperature and low-temperature heating system

4.Pipes for heating and coolling settings in solar energy system

5.Connecting pipe for air conditioner

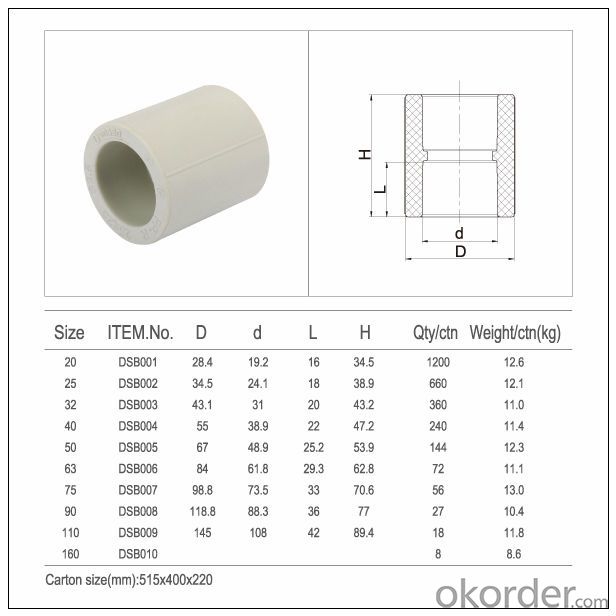

Product Specification

Product name | Size | Weight | Pack |

Equal tee | (Gram/m) | (m/pack) | |

T16 | 12.5 | 1300 | |

T20 | 19.4 | 800 | |

T25 | 30.5 | 450 | |

T32 | 48.2 | 260 | |

T40 | 90.8 | 150 | |

T50 | 142.5 | 106 | |

T63 | 275.3 | 54 | |

T75 | 515.0 | 30 | |

T90 | 712.0 | 18 | |

T110 | 1082.0 | 12 | |

T125 | 1544.0 | 8 | |

T160 | 2531.0 | 4 |

Product Description

FAQ

1.How can I get a quotation from you ?

You can leave us message,and we will reply every message in time.Or we may talk on line by Trademanager.And you can also find our contact information on contact page.

2.Can I get samples before order ?

Yes,of course. Usually our samples are free.

3.what is your delivery time ?

The time of delivery is usually around 1 month(1*40FT as usual).

We can send out in 2 days, if it has stock.

4.How can you garantee what I got will be good ?

We are factory with 100% predelivery inspection which garantee the quality.

5.Q: What's your payment?

A: T/T or L/C at sight

- Q:How do you remove plastic pipe fittings?

- To remove plastic pipe fittings, start by turning off the water supply and relieving any remaining pressure in the pipes. Then, use a wrench or pliers to loosen the fittings by turning them counterclockwise. If the fittings are stubborn, applying heat with a hairdryer can make the plastic more pliable and easier to remove. Alternatively, you can cut the pipe just above the fitting and use a new fitting for replacement.

- Q:Can plastic pipe fittings be used in fire-rated systems?

- No, plastic pipe fittings cannot be used in fire-rated systems. Fire-rated systems require materials that can withstand high temperatures and resist the spread of fire, which plastic fittings are unable to provide.

- Q:Can plastic pipe fittings be used in renewable energy systems?

- Yes, plastic pipe fittings can be used in renewable energy systems. Plastic pipe fittings offer various benefits such as corrosion resistance, lightweight design, and ease of installation. They are commonly used in solar thermal systems, geothermal systems, and other renewable energy applications where durability and longevity are essential.

- Q:Can plastic pipe fittings be used for underground drainage systems?

- Yes, plastic pipe fittings can be used for underground drainage systems. They are commonly used due to their durability, resistance to corrosion, and ease of installation. However, it is important to select fittings that are specifically designed for underground use, as they need to withstand the pressure and environmental conditions associated with burial.

- Q:Can plastic pipe fittings be used with different types of plastic pipes?

- Yes, plastic pipe fittings can generally be used with different types of plastic pipes as long as they are compatible in terms of size and material. However, it is important to check the manufacturer's guidelines and ensure that the fittings and pipes are designed to work together to avoid any compatibility issues.

- Q:How do you connect plastic pipe fittings together?

- To connect plastic pipe fittings together, you typically use solvent cement. This adhesive is applied to the outside of the pipe and the inside of the fitting, and then the two pieces are pressed firmly together. The solvent cement creates a strong bond that securely holds the fittings in place.

- Q:Can plastic pipe fittings be used for chemical storage systems?

- No, plastic pipe fittings are generally not recommended for chemical storage systems as they may not be compatible with the chemicals being stored and could result in harmful leaks or reactions. It is best to use fittings specifically designed for chemical storage systems, such as those made from materials like stainless steel or specialized plastics that are resistant to the specific chemicals being stored.

- Q:Are plastic pipe fittings resistant to thermal expansion?

- Yes, plastic pipe fittings are generally resistant to thermal expansion.

- Q:How do plastic pipe fittings handle thermal insulation requirements?

- Plastic pipe fittings are generally known for their low thermal conductivity, which means they have good thermal insulation properties. This allows plastic pipe fittings to effectively handle thermal insulation requirements by minimizing heat transfer and preventing energy loss.

- Q:How do plastic pipe fittings compare to galvanized steel fittings?

- Plastic pipe fittings offer several advantages compared to galvanized steel fittings. Firstly, plastic fittings are lightweight and easy to install, making them a cost-effective option. They also do not corrode or rust like galvanized steel fittings, which ensures long-term durability and reduces maintenance requirements. Additionally, plastic fittings are resistant to chemicals and have a smooth interior surface, minimizing friction and allowing for better flow. On the other hand, galvanized steel fittings are known for their strength and high-temperature resistance, making them suitable for specific applications where durability is crucial. Ultimately, the choice between plastic and galvanized steel fittings depends on the specific requirements of the project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Water Structure Germany Standard PPR Male Thread Coupling in 2017

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products