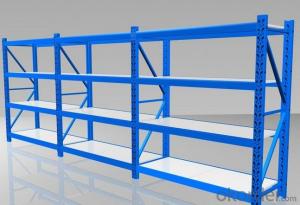

Warehouse Storage Steel Pallet Rack with Highg Quantity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Pallet Rack is a most useful and cost-effective storage racking system providing direct access to all pallets. It provides high capacity storage, is easily installed and adjusted, and has low equipment and capital costs.

Pallet rack features:

1).Speedly and easy installed and adjusted.

2).providing direct access to all pallets .

3).Beam levels are adjustable by 75mm or 76mm.

4).Factory direct sale, Customized sizes are accepted.

Service

1).Size of your warehouse (Length x Width x Clear height)

2).Size(W*D*H) of your pallet

3).How about the loading capacity of each level

4).How many levels you would like

2.Or: pls let us know the size of rack & your required qty,we will send the quotation for you within 24 hours.

FAQ:

What's your advantage?

Only high-quality RAW STEEL, by largest steel factories in China, is used for our racking products.

A big scale of output allows us in a good position to control lower product costs on a basis of same high quality level.

A wide range of different racking types to suit different storage needs.

Free but expert advice & proposed racking solutions for your kind reference.

Quick delivery. Within 20 workdays for ordinary order quantity.

- Q:What are the characteristics of electric power supplies (such as transformers, cables, etc.), mainly in logistics, warehousing and transportation?

- Storage of electric power materials should be prevented from dampness, good rain proof water and moist air intrusion, and electric porcelain equipment should be placed in strict accordance with the requirements, and can not be taken down at will. To prevent collisions and matters should be noted, but also to strengthen ventilation and humidity control and regulation.

- Q:What are the storage facilities and equipment included?

- When the warehousing industry exists as a format, logistics is an effective means to realize value-added services, and warehousing is an indispensable node in the logistics industry.The development of modern logistics industry needs the support of modern warehouse management, and the advanced technology of informatization and the guidance of information technology has become an effective way for the warehousing industry to modernize.

- Q:What are the responsibilities of the warehouse and logistics department?

- Material storage environment must be kept clean and beautiful. Make sure that the materials and facilities in the warehouse are free of dust, and there are no weeds around the cargo yard and the temporary cargo yard.The storage of the goods should be properly clean, strong safety, reasonable and complete, thatch pad material sign marks. Fixed location of storage of materials to implement the "four position" and "55 stack", and to comply with the quality system, environment / safety management system standards.Warehouse management of inventory must be in accordance with the "six check" content, check, check, check the number of quality measurement tools, storage method, check, check the safety check, serious circulation from the point, since the rate of not less than 50% months, or two months in the inventory of all materials to all at a time. The number of correct inventory requirements, consistent with accounts, no account materials, and make self recording.For materials that need temperature and humidity control, the storage procedures for special requirements must be strictly enforced, daily monitoring of temperature and humidity shall be carried out and records shall be duly made.

- Q:What's the sea cucumber logistics equipment?

- Sea cucumber contains a lot of nutrients, can strengthen the body, nourishing Yin, beauty, you can simply use "life preservative" to describe. The sea cucumber is rich in nutrition, in which some characteristics of components, namely with low cholesterol, fat content is relatively small, is a typical high protein, low fat, low cholesterol food, and is especially suitable for patients with hypertension, hyperlipidemia and coronary heart disease.

- Q:Storage facilities and equipment is not perfect, what?

- Increase the hardware input to the warehouse.This includes warehouse construction and renovation, purchase of new shelves, pallets, digital automatic identification system and sorting, processing, packaging and other logistics equipment, greatly enhance the level of automation of existing warehouse and logistics operation efficiency, increase the function of logistics services.

- Q:How to carry out logistics warehousing operations?

- Whether we can allocate human resources and operate effectively is one of the most important criteria for efficient warehouse management.Artificial management technology can help those who are troubled employees warehousing enterprises, auxiliary management decision-making staff number storage required, and can adopt the labor standards and engineering support system to evaluate the performance of warehouse workers. In addition, companies should provide incentives for teams of employees, not individuals, to maximize the team's potential. There are many warehouse management systems lack of artificial management and performance evaluation considerations, or the lack of manual management of this function of convergence.

- Q:What are the commonly used automation equipment in warehouse logistics?

- Such as the commonly used transport equipment, the car these

- Q:What are the problems in e-commerce, logistics and warehousing?

- The logistics industry is between the supplier and the buyer of the third party, to serve as the first purpose. Compared with other domestic industries or sectors of China's logistics industry development lags behind, compared with the development of modern logistics industry in the world, in terms of resource allocation, service level, management level, the use of modern means of science and technology, there is a big gap. Mainly for the logistics infrastructure planning unreasonable, in transportation and transportation, line mileage, density and a low level of modernization, weak ability to resist natural disasters; in storage, our country is in the administrative department for the establishment of the warehouse system, size, number and storage equipment modernization level is low; in addition, the entire logistics industry level of logistics management and logistics information level are relatively low.

- Q:What are the categories of logistics?

- The main focus of traditional logistics is warehousing and inventory management and delivery, and sometimes the main focus is on warehousing and transportation to make up for differences in time and space. Integrated logistics not only provide transportation services, including many coordination of the entire supply chain management, such as management of transportation, warehousing department and some other distributors, including order processing, procurement etc.. Because much effort is put on supply chain management, more responsibility and more complex management, which is different from traditional logistics.

- Q:What are the common logistics equipment?

- According to the equipment in the logistics activities in a considerable position, can be divided into fixed equipment and movable equipment. Fixed equipment such as railway, highway, bridge and tunnel; stations, ports, warehouses and other buildings I equipment such as train, cars, ships, mobile handling equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Warehouse Storage Steel Pallet Rack with Highg Quantity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords