Medium Type Pallet Racking Systems for Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Medium duty pallet racking system is commonly used in manufacturing industry and logistics inductry, like logistic centre.

It's both suitable for samll goods and big goods, in large quantity or not. Heavy duty pallet rack is used in high warehouse and super high warehouse. Automatic warehouse also use this kind of racking system.

Feature:

· Customized design

· Big loading weight

· Professional service

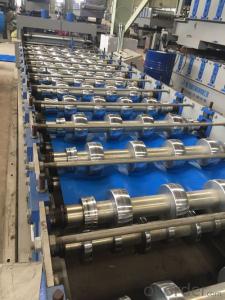

Images:

Specifications:

Loading weight | 3000KG |

Height | 8-12M customized |

FAQ:

What is note for purchase?

Pallet size,good weight, warehouse sapce and height, etc.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation.

- Q:What are the main differences between the electricity supplier warehouse and the traditional warehouse?

- Single SKU inventory is low. Compared with the traditional retail stores, e-commerce sales platform without traditional space limit, so in order to attract and meet the needs of more customers, sales of electricity supplier SKU to more comprehensive, such as Amazon and dangdang etc. there are hundreds of thousands, millions of SKU. But because the storage space can not be unlimited expansion, how to put more SKU in the limited storage space, you need each SKU less than the amount of goods. As a result, the storage units in the electricity supplier warehousing logistics are dominated by boxes instead of traditional pallets. From the choice of storage equipment, the main choice of box shelves, such as shelf shelves or medium-sized shelves, rather than pallet shelves. In the aspect of operation strategy, most storage and picking are one, and a small amount of SKU distribute storage and picking space, and there is a replenishment operation from storage to picking.

- Q:What's the sea cucumber logistics equipment?

- Sea cucumber contains a lot of nutrients, can strengthen the body, nourishing Yin, beauty, you can simply use "life preservative" to describe. The sea cucumber is rich in nutrition, in which some characteristics of components, namely with low cholesterol, fat content is relatively small, is a typical high protein, low fat, low cholesterol food, and is especially suitable for patients with hypertension, hyperlipidemia and coronary heart disease.

- Q:The role of warehouse management in Enterprises

- Its functions and tasks are mainly:1, the use of market economy means to obtain the largest allocation of storage resources.2, the principle of high efficiency organization management.3, continue to meet the needs of the community as the principle of business activities.4, with high efficiency, low cost as the principle of organizing warehouse production.5, to high-quality services, credit, establish corporate image.6, through the institutionalization, scientific advanced means, and constantly improve the management level.7, from technical to spiritual areas to improve staff quality.

- Q:What is the warehouse keeper in the logistics industry?

- Job responsibilities include:1, obey the leadership, comply with the rules and regulations.2. Be responsible for daily warehouse management.3, according to the actual work situation, actively put forward the rationalization proposals of operation and management.4, according to the provisions of the warehouse charge.5, materials into the warehouse, the position of the layout and correct placement.6 、 warehouse safety work and material storage and protection work.7, the correct opening of the operating documents, confirmation and handover.8. Daily material detail registration.

- Q:What is the storage fee?

- Warehousing cost is the material supply and marketing enterprises in the purchase of goods, acceptance, warehousing, storage of materials in the process of payment of all costs. Warehousing costs paid to the storage warehouse storage and transportation, as well as the subsidiary enterprise in the warehouse transfer handling, inspection, repair, maintenance, selecting and sorting, packaging, inventory loss, and wages, workers from the welfare expenses and other expenses.

- Q:How to strengthen the integration and construction of logistics infrastructure

- function of specialized facilities. In order to provide logistics organization service in accordance with the cost, efficiency and service requirements, the construction of specialized logistics facilities should be carried out in accordance with the specialized facilities so as to have the corresponding functions of the integrated logistics organization.Logistics Centre。 The physical facilities is to have for social services, logistics services (field station, warehouse and equipment), improve the information network and service capabilities are available, the larger the scope of radiation, to small species, large storage capacity requirements, can be unified operation and management of supply chain logistics business functions.Distribution Centre。 To have the physical facilities to provide services, goods distribution services for specific users (field station, warehouse and equipment), improve the information network and service capabilities are available, the radiation range mainly for sale to city or enterprise network as the basis, to adapt to many varieties of small batch high frequency distribution requirements, to the delivery service for both main products inventory control and storage services and other functions;Logistics Park。 The function of the logistics centers, distribution centers and other specialized comprehensive facilities and professional facilities, transport stations, warehousing and other single function together, can provide a variety of forms and links of the logistics service organization.

- Q:What are the irrational aspects of warehousing in logistics?

- Systematization of logistics objective. Modern logistics systems from the perspective of the overall planning of a company all the logistics activities of the whole, and relationships between handle logistics activities and business activities and objectives of the company logistics activities and logistics activities, the optimization for a single event, but the overall optimization activities.

- Q:Common equipment for warehouse logistics equipment

- Warehouse logistics: solid shelves, stacking machines, sorting lines, conveyor equipmentVertical conveying type: Reciprocating lift, continuous elevator, intermittent elevator and hydraulic lifting platformFlat conveyor: belt conveyor, chain machine, roller and other non-standard conveying equipmentNon-standard equipment: climbing belt conveyor (chain machine), turning belt conveyor (chain machine), screw conveyor, etc.

- Q:The disadvantages of traditional warehousing and the advantages of modern warehousing

- Chinese traditional warehousing industry is the product of the planned economy, then they are mainly to provide warehousing and a small amount of short distance transport services for the industry's material or commercial enterprise, which is engaged in the traditional logistics business, the low level of information technology, the extensive mode of operation, the economic benefit is not good.

- Q:What is lean storage?

- Lean warehousing is the lean management of warehouse management. Here are some information to find. I hope it will help you

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Medium Type Pallet Racking Systems for Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords