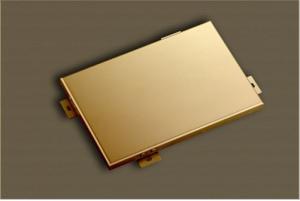

Wall cladding panel, Various Colors option, Good Decorative Effect

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 900 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Key Specifications/Special Features

Specifications:

PVDF solid aluminum panel curtain wall panel

Features:

Light, high-strength, and high-rigidity

Excellent weather resistance and anti-corrosion

Good process ability, able to fabricate into flat, arc, globe and other complicated shapes

Techniques: bending, welding, polishing, painting

Various colors, good decorative effect

Difficult to be contaminated, good self-cleaned

Easy to be installed, able to be recycled, environmental friendly, effect like in the picture

Model Number:FD-SAP-49

Brand Name:Fangda (Famous)

MOQ:300 Sheets

FOB Price: US$ 3 - US$ 18

FOB Port:China (Mainland)

Lead Time: 5 - 15 days

Payment Terms:Letter of Credit (LC, L/C)

Country of Origin:China (mainland)

- Q:Urgent: pvc board, aluminum plate, aluminum buckle plate What is the difference

- Aluminum plate - is the decorative plate, up to the external walls, billboards; on Zhang pricing, the size of wood board, 40-200;

- Q:What is the meaning of the number of silk

- Of course, this name is not standardized, but the convention, we understand the total recognition of the need to deliberately correct.

- Q:3.6mX1.5 bathroom 3.6mx2.1 kitchen with aluminum plate ceiling. Using wooden skeleton, made of removable. Seeking solutions. Thank you! The How much is the cost? The

- The wooden keel is fixed in the transverse direction, and the fixing points are installed in the installation position (4-sided wall) with the wooden strips. The hinges, the latches or the more professional hardware fittings (such as the plug-type hinges, hinges, etc.) When dismantling, first remove the buckle plate, pull out the bolt, the wooden keel is removed. If it is aluminum buckle plate, you can try to play a 30cmX30cm wood keel, and then the aluminum slab of the special light steel keel fixed on the wooden side, the remaining steps above, and then the aluminum plate into the light steel keel The

- Q:Aluminum-plastic curtain wall construction in winter, with the real paste can you?

- Another winter weather should also be divided into regions, such as the winter of winter and winter in Hainan,

- Q:OKorder Huayuan aluminum composite panel is not the best

- Like Walter, Huatian Aluminum, Yali Tai, Huayuan, Haida, Rainbow, the future of the window are aluminum-plastic board industry which is a good brand

- Q:Aluminum plate and plastic plate prices, the more detailed the better, thank you

- Thickness 3 mm, aluminum thickness 0.12 + 0.12 mm, 185 yuan / sheet.

- Q:9 meters high aluminum plastic door door fee is how much, Xuzhou area

- Xuzhou area of the labor costs should not be cheap. This highly operational estimates also need 80-120 yuan / square meter it.

- Q:Aluminum-plastic plate production line inverter has a specific role, can specifically say it?

- Three crystal inverter successfully used in Haier electrical appliances, Rong Sheng refrigerator spray production line

- Q:Aluminum-plastic plate punch what equipment

- In addition, the hole and the law can use the punch and die to engage

- Q:What is the panel decoration

- Aluminum-plastic plate varieties are more, and is a new type of material, so there is no uniform classification method, usually by purpose, product features and surface decoration effect classification.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wall cladding panel, Various Colors option, Good Decorative Effect

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 900 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords