PVDF Aluminium Composite Panel with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

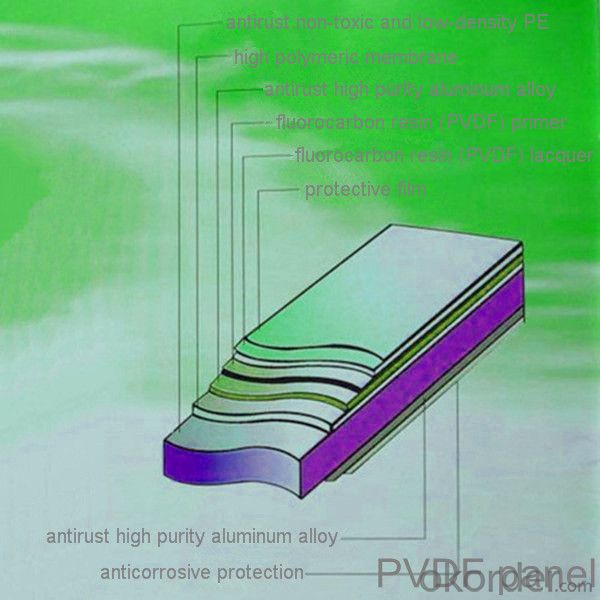

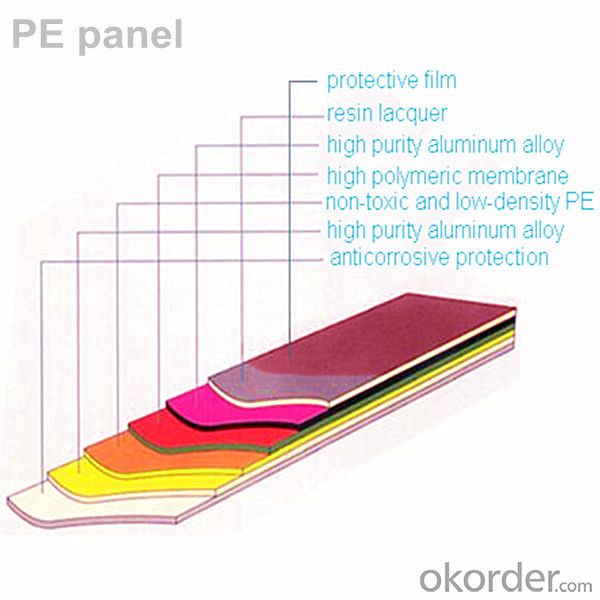

1.Structure of PVDF Aluminium Composite Panel Description:

By adopting PVDF paints from the two toppest paint supplier: American PPG and Sweden Beckers, Megabond PVDF Aluminum Composite Panel is the most ideal material for facade cladding, curtain wall cladding and other outdoor using purpose.

PVDF is short for Polyvinlylidene Fluoride, the color will have no obvious change within 15 to 20 years when it’s applied outdoor. PVDF paint should be 2-layer coating or 3-layer coating, and Painting Thickness ≥25um., Fluorocarbon Powder ≥70%.

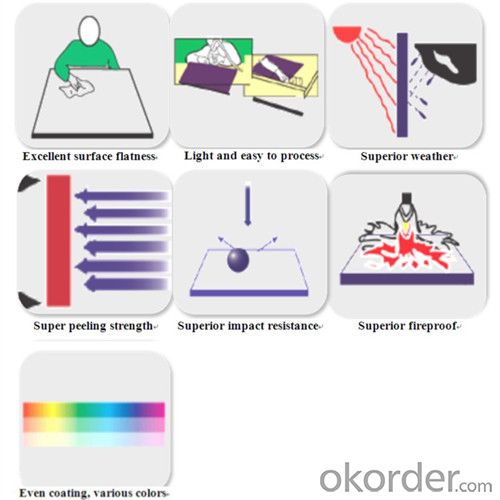

2.Main Features of the PVDF Aluminium Composite Panel :

1) Building exterior curtain wall, purdah wall;

2) Decoration and renovation additions for old buildings;

3) Decorations of interior walls (ceilings, partitions, bathrooms, cabinet, counter,

video wall, shield for doors windows, skirting, kitchens and balconies.)

4) Shop door decorations;

3. PVDF Aluminium Composite Panel Image:

4. PVDF Aluminium Composite Panel Specification

| Aluminum alloy | AA1100 series,AA3003 series |

| Aluminum skin | 0.30mm,0.40mm,0.45mm,0.50mm |

| Thickness | 4mm,5mm,6mm |

| Width | 1220mm,1250mm,1500mm,1575mm |

| Length | up to 6000mm |

| Color | 30 kinds.Special color available upon request |

5.FAQ

1).How to choose the panel thickness for different usages?

Exterior usage: 4mm panel with 0.30mm,0.40mm or 0.50mm aluminum skin, better in PVDF coating.

Interior usage: 3mm panel with 0.10mm,0.15mm or 0.21mm aluminum skin, PE coating is ok.

2). How to check whether this product is in good quality?

A. First is to see whether the surface is smooth enough, no ripples, bubbles and scratches.

B. Second is to check whether the panel thickness and aluminum skin thickness is thick enough.

C. To check the core material, whether it's easy broken.

D. To test the peel strength between aluminum skin and the core .

E. See whether company is normal manufacturer, which have ISO, CE, SGS certificate.

....

3). How to confirm the color for what you want?

You can contact me for our color card.

You can also choose a color from the RAL/Panton color card.

- Q:Aluminum veneer, aluminum-plastic plate clerk after the completion of the project, how to allow customers the shortest time remittance? What if the customer is always not remitting?

- Go to the customer home squatting

- Q:Analysis of why the surface of aluminum-plastic plate deformation, from the drums

- Casually in which city in the circle, are not difficult to find some aluminum-plastic plate surface deformation, from the drums of those big unpleasant works. Small facade renovation works on this phenomenon, large high-rise buildings also have this phenomenon. In the construction, the emergence of such a quality problem, we have considered the quality of the plate itself; later, after we focus on the analysis found that the main problem lies in the paste sheet of aluminum-plastic plate, followed by aluminum The quality of the board itself. Dealers often provide us with aluminum-plastic plate construction process, the recommended use of grass-roots materials are mainly high-density board, woodworking board, etc. In fact, such materials used in the outdoor, its life is Very fragile, after the wind, sun, rain, will inevitably produce deformation. Since the grass-roots materials are deformed, then as the surface of the aluminum-plastic plate that is not deformed? Can be seen, the ideal outdoor base material should be After the rust treatment of angle steel, square steel pipe to form a skeleton is better.If the conditions permit, then use aluminum as a skeleton is more ideal. This type of metal material produced skeleton, the cost is not higher than the wood keel, high density Many, can really guarantee the quality of the project.

- Q:Rush! What is the glue between aluminum and plastic?

- Aluminum plastic plate aluminum and plastic composite plastic called: polymer hot melt film.

- Q:China aluminum-plastic plate door decoration materials, where to buy a good point? Have prawn help?

- To Kunming cloud like building materials to buy, they are a set of aluminum-plastic plate, aluminum veneer production and wholesale as one of the large curtain wall decoration materials business, the introduction of the quality of aluminum-plastic plate is very good.

- Q:Aluminum panels are used in what areas, can not be more detailed.

- Aluminum-plastic composite panel referred to as aluminum-plastic plate, is made by the surface treatment and coated with aluminum paint as the surface, polyethylene plastic plate as the core layer, after a series of process processing complex made of new materials.

- Q:What is the difference between aluminum and aluminum?

- Another method of surface treatment of curtain wall aluminum is electrostatic spraying. Spray is divided into powder spray and liquid spray. Powder coating materials are: polyurethane, polyester resin, epoxy resin and other raw materials with high color retention pigment, can be dozens of different colors of spray powder. The spray powder, resistant to collision-resistant friction, under the impact of 50 kg, aluminum deformation, no crack coating, no loss of complete intact, anti-acid and mortar. The only shortcomings afraid of long-term exposure to ultraviolet light, a few years later prone to the color difference between yin and yang face. Many manufacturers of domestic production of spray powder, the weight difference is very large, and some powder with dust This powder in the hanging after the wall, with the sun angle changes in the day and evening changes, the color difference between the wall color, Choose powder spray paint Greek attention. Liquid spray coating that is fluorocarbon polymer spray, commonly known as fluorinated carbon spray coating, is used to make paint fluorocarbon polymer resin, metal cover paint, and fluoride is the combination of the most solid molecules The

- Q:What is the aluminum plate and fire board, what is the difference?

- Fire board is the paper immersed in the resin, after high temperature and high pressure treatment, the production of interior decoration surface materials. Fire board with wear, heat, impact resistance, acid and alkali, fire and other characteristics. Fire board can be used for table, desktop, wall, kitchen utensils, office furniture, door surface, hanging cabinet and other locations

- Q:How much is a square meter?

- Easy to operate the external wall dry aluminum plate offer 300 yuan a square, high-altitude operations, modeling complex,

- Q:What is aluminum curtain wall?

- The main material used in the facade decoration is the use of aluminum-plastic plate works, focusing on a certain height of the building facade.

- Q:Bedroom room tide, often out of the wall, just finished a year began to fall out, and then also out of the decoration, wallpaper stickers also up, the basic wall can not get anything, want to use the plate to the wet wall separated, Can I use aluminum or aluminum gusset? Or other plates? Which is more suitable for the bedroom, and is a large area

- You can use aluminum-plastic panels, but if you want to look better than the space, aluminum-plastic plate inside to play keel to do, the effect is good, rich color cut easily shape, you want to brush the paint inside the wall to shovel and then brush strong.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVDF Aluminium Composite Panel with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords