nano aluminum composite panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

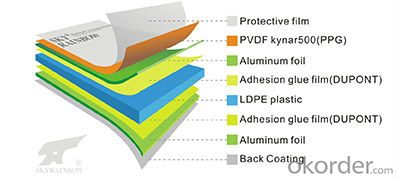

Material of Aluminum composite panel

A) Front : aluminium alloy sheet coated with PleochromaticPVDF paint on surface B) Core: nontox low density polyethylene C) Back: aluminium alloy sheet coated with polyester resin painting D) Surface coating thickness: 32μ±1μ E) Aluminium alloy: 3003 H24 F) Sheet thickness: 0.3mm,0.4mm,0.5mm |  |

Specification of aluminum decorative panels

| | |

| Surface | PE or PVDF,Nano,Brushes,Mirror,Marble Look,Wooden Look,Glossy |

| Core | LDPE, Fireproof |

| Back Side | Primer or Mill Finish |

| Aluminum thickness | 0.06-0.50mm |

| Panel thickness | 2mm, 3mm, 4mm, 5mm,6mm |

| Width | 1220mm, 1250mm, 1500mm,1550mm,Less Than 1570mm |

| Length | Any Length Less Than 6000mm |

Advantage of aluminum decorative panels

1) Excellent fireproof performance & heat insulation, sound insulation

2) Weather resistance, high strength, high plasticity

3) , good impact resistance, quakeproofs performance and reducing buildings load

4) Various colors , convenient installation, easy maintenance

5) Widely used in galleries, exhibitions, saloons, stores, offices, banks, hotels, restaurants and apartments etc

- Q:OKorder aluminum-plastic composite board where to sell?

- Cloud like building materials have aluminum-plastic composite board sales

- Q:White aluminum plate can be a new brush color? Store white aluminum-plastic board for a long time dirty, you can buy a new paint back to brush it?

- If the quality of the white aluminum plate is poor, it is hard to scrub clean for a long time.You can buy a polyester paint ...

- Q:Can the foamed cement composite board paste the aluminum plate?

- This ensures the adhesion between the aluminum plate and the backing plate.

- Q:The inside of the wall tiles do not do waterproof, I would like to paste the aluminum plate on the tiles, thoroughly waterproof. This process can not be achieved ??

- Ignore the waterproof factors, aluminum-plastic board is generally attached to the wood board or MDF, will be properly coupled with the thin aluminum-plastic plate directly attached to the tile, and soon after the surface will be wavy.

- Q:3d board and aluminum plate prices? What kind of price?

- This is to sub-material, generally relatively high prices of aluminum-plastic plate

- Q:OKorder Huayuan aluminum composite panel is not the best

- The quality of aluminum-plastic plate is the customer's own requirements, each manufacturer can produce customer requirements of the plate, in the aluminum-plastic plate industry, each manufacturer has its own position, like OKorder auspicious. End plate, to building materials market for the sales channels: Huayuan, Taiwan auspicious, Mitsubishi. A Luke state to the main high-end, mainly to the project-based friends, some large chain store store decoration will generally use these brands. OKorder Bank Bank of Communications on the use of Taiwan auspicious (auspicious card) Bank of China with Huayuan ... you can according to their own requirements to choose the right for your manufacturers.

- Q:What is the composition of aluminum-plastic panels?

- Aluminum-plastic composite panels are made of multi-layer composite material, the upper and lower layers of high-purity aluminum alloy plate, the middle of non-toxic low-density polyethylene (PE) core board, the front also paste a protective film. For outdoor, aluminum-plastic panels coated with fluorocarbon resin (PVDF) coating, for the interior, the front can be non-fluorocarbon resin coating.

- Q:Anhui where the production of aluminum veneer aluminum PE board PP PP

- Around the Zhejiang, Henan, Shandong several provinces have the corresponding manufacturers can contact.

- Q:China where auspicious aluminum-plastic plate manufacturers? I have a lot of aluminum plastic panels.

- In China's words there is no auspicious aluminum-plastic plate manufacturers

- Q:What is the difference between stretching aluminum and hot-rolled aluminum? What is the concept of stretching aluminum?

- The production process of aluminum plate is hot rolling, casting rolling, casting, etc., in which the aluminum plate made by hot rolling is superior to the aluminum produced by other processes in the aspects of stretching, oxidation and so on.With the cost of hot plate Production costs are relatively high.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

nano aluminum composite panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords