Vertical Structure Support System for Push Pull Prop

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

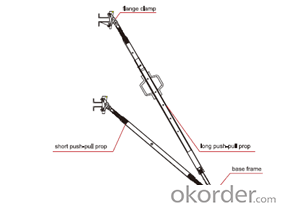

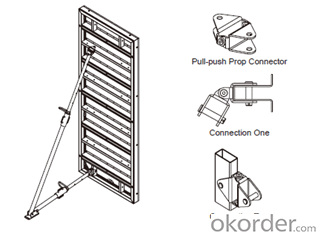

1. Structure of Push Pull Prop

Pull-push prop are used for supporting the wall and column formwork.

1.) For Timber Beam Formwork

2.) For Steel Frame Formwork

2. Main Features of Push Pull Prop

◆ High degree of standardization

◆ Simple site operations

◆ Quick adjustment

3. Push Pull Prop Images

4. Single Side Bracket Specifications

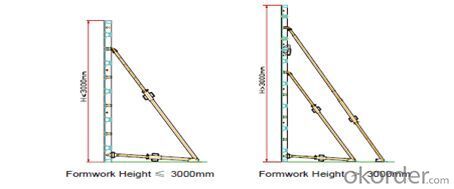

There are three kinds of pull-push props, A,B,C. The A and B is suitable for the formwork not higher than 3000mm; C is suitable for the formwork higher than 3000mm as a reinforcer.

5. FAQ of Single Side Bracket

1) What can we do for you?

.We can ensure the quality of the push pull prop and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:Steel braced steel purlin and anchor beam waist connection

- Disclaimer: about the steel braced steel purlin and anchor beam waist connection should be clear in the construction scheme, construction technology scheme. In order to ensure the safety, the force and the state of the joint shall be determined by calculation, including the diameter of the anchor cable, the material requirements and the safety factor, the welding seam height, etc.. After the establishment of the technical scheme, the technical department should be organized to discuss the special measures to ensure the safe operation of the project, and it should be implemented in accordance with the procedure. Reiterate: before the construction of a variety of resources are fully prepared, the construction should adhere to safety first.

- Q:Are steel props resistant to impact or vibration?

- Yes, steel props are generally resistant to both impact and vibration due to their sturdy construction and high tensile strength.

- Q:Can steel props be used in different weather conditions?

- Yes, steel props can be used in different weather conditions. Steel is a strong and durable material that can withstand various weather conditions such as rain, wind, and extreme temperatures. However, it is important to ensure proper maintenance and protection to prevent rust and corrosion that can be caused by prolonged exposure to harsh weather elements.

- Q:Are steel props adjustable in small increments?

- Steel props can be adjusted in small increments, providing precise leveling and support in construction projects. These adjustable steel acrow props, also referred to as adjustable steel props, are widely used in construction and temporary support systems. Featuring a telescopic inner tube and an outer tube, they allow for different height adjustments in small increments. This versatility makes steel props suitable for a variety of applications, ensuring stability and safety on construction sites.

- Q:Are steel props suitable for supporting temporary art installations or sculptures?

- Steel props offer a reliable and versatile solution for supporting temporary art installations or sculptures. They are suitable because steel is known for its strength, durability, and load-bearing capacity. These qualities make it an ideal choice for supporting heavy and intricate artworks. Additionally, steel props can be easily customized to meet the specific requirements of the installation or sculpture. They can provide stability, balance, and secure placement, ensuring the artwork remains safely supported throughout its display period. Moreover, steel props allow for flexibility as they can be adjusted in height and angle, allowing for optimal viewing angles. In conclusion, steel props guarantee the safety and longevity of temporary art installations or sculptures.

- Q:Are steel props adjustable in both length and width?

- Generally, steel props are only adjustable in terms of length, not width. A screw thread mechanism is used to extend or retract the prop to the desired height. However, the distance between the two ends of the prop is typically fixed and cannot be altered. This is because the prop's width is determined by its design and construction, and modifying it could potentially impact its stability and ability to bear weight.

- Q:Can steel props be used in confined spaces?

- Yes, steel props can be used in confined spaces. Steel props are adjustable and collapsible temporary support structures commonly used in construction to provide vertical support to ceilings, walls, or beams. They are versatile and can be adapted to fit various spaces, including confined areas, as long as they meet the necessary safety requirements and are properly installed and secured.

- Q:How do steel props compare to hydraulic jacks in terms of performance?

- Steel props and hydraulic jacks have different characteristics that affect their performance. Steel props are sturdy and reliable, providing excellent load-bearing capacity and stability. They are commonly used in construction projects to support temporary structures or provide additional reinforcement. On the other hand, hydraulic jacks offer adjustable height and greater ease of use, making them suitable for lifting heavy loads or vehicles. Overall, the choice between steel props and hydraulic jacks depends on the specific requirements of the task at hand.

- Q:Can steel props be used for temporary support in railway bridge construction?

- Yes, steel props can be used for temporary support in railway bridge construction. Steel props are commonly used in construction projects to provide temporary support and stability, and they can effectively withstand heavy loads and provide structural integrity during the construction process.

- Q:What are the common safety features of steel props?

- Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and renovation projects to support temporary structures and provide stability. These props have several safety features to ensure the protection of workers and prevent accidents on the job site. 1. Adjustable Height: Steel props are designed with a telescopic mechanism that allows for easy adjustment of the height. This feature ensures that the props can be set at the appropriate level to provide optimal support and stability. 2. Load Capacity: Steel props are engineered to withstand heavy loads. They are typically manufactured with robust materials and are tested to meet specific load-bearing capacities. This ensures that the props can safely support the weight of temporary structures or heavy construction materials. 3. Locking Pins: To prevent accidental collapse or height adjustment, steel props are equipped with locking pins. These pins securely hold the prop at the desired height and prevent any accidental changes. The locking mechanism provides additional safety by ensuring that the prop remains stable throughout the construction process. 4. Prop Head Plate: Steel props feature a flat prop head plate at the top, which provides a larger surface area for distributing the load. This design helps to prevent damage to the supported structure and reduces the risk of the prop sinking into the ground or causing instability. 5. Non-Slip Base Plate: The bottom of the steel prop is typically equipped with a non-slip base plate. This feature improves stability by preventing the prop from slipping or sliding on smooth or uneven surfaces. The non-slip base plate ensures that the prop remains securely in place, reducing the risk of accidents caused by prop movement. 6. Powder Coating or Galvanization: Many steel props are coated with a layer of powder or are galvanized to protect them from corrosion and rust. This protective coating enhances the durability and longevity of the props, ensuring they remain safe to use for an extended period. In conclusion, common safety features of steel props include adjustable height, a high load capacity, locking pins, a prop head plate, a non-slip base plate, and a protective coating. These features are designed to ensure the stability, reliability, and safety of steel props during construction and renovation projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vertical Structure Support System for Push Pull Prop

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords