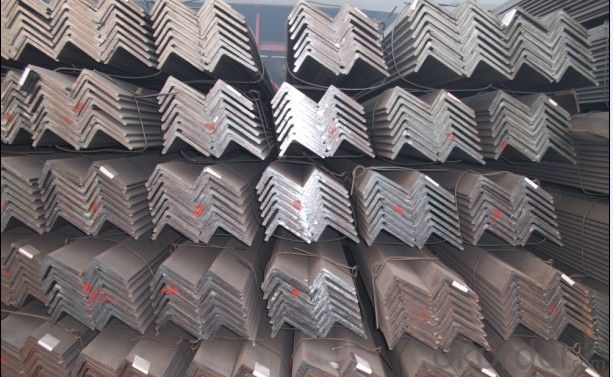

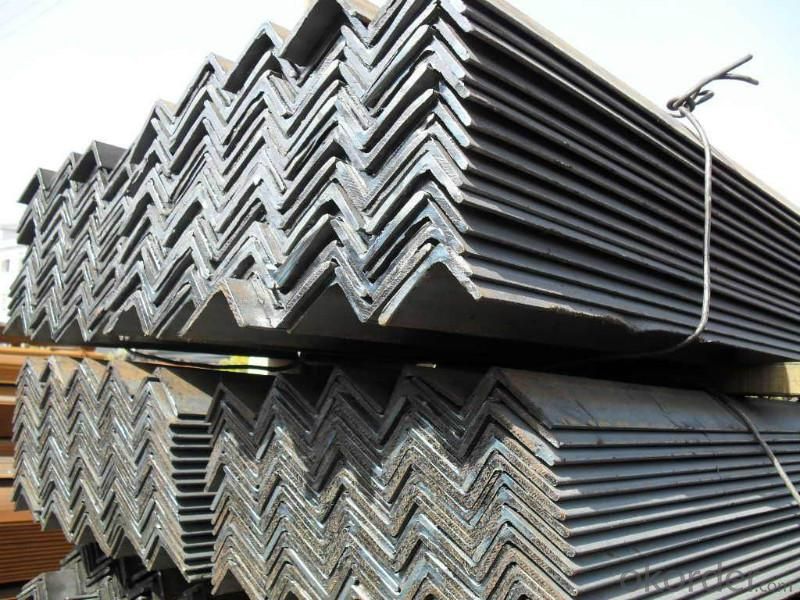

Unequal Steel Angle Mild Hot Rolled Low Carbon Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Unequal Steel Angle Mild Hot Rolled Low Carbon Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Steel Angle Mild Hot Rolled Low Carbon Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Steel Angle Mild Hot Rolled Low Carbon Steel are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

| UNEQUAL ANGLE STEEL | |||||

| size(mm) | a(mm) | a1(mm) | thickness(mm) | kg/m | length(m) |

| 75*50*5 | 75 | 50 | 5 | 4.808 | 6m,9m,12m |

| 75*50*6 | 75 | 50 | 6 | 5.699 | 6m,9m,12m |

| 75*50*8 | 75 | 50 | 8 | 7.431 | 6m,9m,12m |

| 100*75*7 | 100 | 75 | 7 | 9.34 | 6m,9m,12m |

| 100*75*8 | 100 | 75 | 8 | 10.6 | 6m,9m,12m |

| 100*75*9 | 100 | 75 | 9 | 11.8 | 6m,9m,12m |

| 100*75*10 | 100 | 75 | 10 | 13 | 6m,9m,12m |

| 100*75*12 | 100 | 75 | 12 | 15.4 | 6m,9m,12m |

| 125*75*7 | 125 | 75 | 7 | 10.7 | 6m,9m,12m |

| 125*75*8 | 125 | 75 | 8 | 12.2 | 6m,9m,12m |

| 125*75*9 | 125 | 75 | 9 | 13.6 | 6m,9m,12m |

| 125*75*10 | 125 | 75 | 10 | 15 | 6m,9m,12m |

| 125*75*12 | 125 | 75 | 12 | 17.8 | 6m,9m,12m |

| 150*90*8 | 150 | 90 | 8 | 14.7 | 6m,9m,12m |

| 150*90*9 | 150 | 90 | 9 | 16.4 | 6m,9m,12m |

| 150*90*10 | 150 | 90 | 10 | 18.2 | 6m,9m,12m |

| 150*90*12 | 150 | 90 | 12 | 21.6 | 6m,9m,12m |

| 200*100*10 | 200 | 100 | 10 | 23 | 6m,9m,12m |

| 200*100*12 | 200 | 100 | 12 | 27.62 | 6m,9m,12m |

| 200*100*15 | 200 | 100 | 15 | 34.04 | 6m,9m,12m |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q4: How many tons of steel products could be loaded in containers?

A4: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q:What are the different methods of fire protection for steel angles?

- There are several different methods of fire protection for steel angles, depending on the specific requirements and regulations. Some common methods include: 1. Passive Fire Protection: This involves applying fire-resistant materials directly to the steel angles. These materials can include fire-resistant coatings, fireproofing sprays, or intumescent paints. These coatings can help delay the spread of fire and provide insulation, protecting the steel angles from the high temperatures produced during a fire. 2. Encasement: Another method is to encase the steel angles in fire-resistant materials such as concrete or gypsum board. This creates a barrier between the steel and the fire, preventing it from reaching critical temperatures that could cause structural failure. 3. Fireproofing Systems: Fireproofing systems involve the use of fire-resistant boards or panels that are attached to the steel angles. These systems provide a layer of insulation and protection against fire, preventing the steel from heating up quickly and maintaining its structural integrity for a longer period. 4. Sprinkler Systems: Installing sprinkler systems can also help protect steel angles from fire. These systems are designed to detect and suppress fires by releasing water or fire-suppressing agents when triggered. By quickly extinguishing the fire, the sprinklers can prevent the steel angles from reaching critical temperatures. 5. Fire-resistant barriers: Fire-resistant barriers, such as fire-resistant walls or curtains, can be utilized to separate steel angles from potential fire sources. These barriers can help contain the fire and prevent it from spreading to the steel angles, providing an additional layer of protection. It is important to consult with fire protection experts, engineers, and local building codes to determine the most suitable method of fire protection for steel angles in a specific setting. The choice of method may depend on factors such as the type of building, fire safety requirements, and the level of fire risk involved.

- Q:Are steel angles suitable for mezzanine floor construction?

- Yes, steel angles are suitable for mezzanine floor construction. Steel angles provide structural support and stability, making them a popular choice for building mezzanine floors. They are strong, durable, and can withstand heavy loads, making them an ideal choice for creating additional floor space in industrial or commercial settings.

- Q:What are the common surface treatments used for steel angles?

- The common surface treatments used for steel angles are galvanizing, painting, and powder coating. Galvanizing is a process where a layer of zinc is applied to the surface of the steel angle to protect it from corrosion. This is achieved by immersing the steel angle in a bath of molten zinc or by applying a zinc coating using a specialized technique. Galvanized steel angles have a shiny, silver appearance and provide excellent corrosion resistance. Painting is another commonly used surface treatment for steel angles. The steel angle is typically primed and then coated with one or more layers of paint. This not only enhances the aesthetic appeal of the steel angle but also provides a protective barrier against rust and other environmental factors. Painting allows for a wide range of color options and finishes, making it a versatile choice for various applications. Powder coating is a dry finishing process where a fine powder, typically made of resin and pigment, is electrostatically applied to the steel angle's surface. The angle is then heated, causing the powder to melt and form a durable coating. Powder coating offers excellent resistance to scratches, chemicals, and UV rays. It is available in a wide array of colors and provides a smooth and even finish. The choice of surface treatment for steel angles depends on the specific application and the desired level of protection, aesthetics, and durability. Galvanizing is preferred in outdoor or corrosive environments, while painting and powder coating are commonly used for indoor applications or where a specific color or finish is desired.

- Q:How do you determine the appropriate thickness of a steel angle for a specific application?

- To calculate the suitable thickness of a steel angle for a specific purpose, several factors must be taken into consideration. Firstly, it is crucial to comprehend the load or weight that will be exerted on the steel angle. This includes both the static load, which refers to the continuous weight the angle will bear, and the dynamic load, which signifies any intermittent additional force. The magnitude of the load will determine the strength requirements of the steel angle. Secondly, the length of the steel angle needs to be accounted for. Longer angles will experience more deflection and bending, thus necessitating a thicker angle to ensure adequate rigidity and prevent deformation under the load. Another critical factor to consider is the type of steel being utilized. Different steel grades possess varying strength properties, and the appropriate thickness will depend on the specific grade. It is essential to consult the material specifications and standards to ensure the selected steel angle meets the necessary strength and durability criteria for the intended application. Additionally, the support conditions and the method of attachment should be taken into account. The manner in which the steel angle is connected to other structural elements will impact its load-bearing capacity. If the angle is bolted or welded to other components, its thickness must be selected to suit the particular connection method and accommodate any additional stresses induced during the attachment process. Lastly, it is important to adhere to any applicable industry standards, codes, or regulations when determining the suitable thickness of a steel angle. These standards often provide guidelines or calculations for selecting the correct size and thickness based on the intended application, load, and other design factors. In conclusion, determining the appropriate thickness of a steel angle for a specific application necessitates considering factors such as the load magnitude, length, steel grade, support conditions, and attachment method. Consulting material specifications, industry standards, and seeking professional advice can ensure that the chosen steel angle meets the required strength and durability specifications.

- Q:Can steel angles be painted?

- Yes, steel angles can be painted. The process of painting steel angles involves cleaning the surface, applying a primer, and then applying the desired paint. The primer helps to create a smooth and even surface for the paint to adhere to, while also providing additional protection against corrosion. Once the primer is dry, the paint can be applied using a brush, roller, or spray gun. It is important to choose a paint that is specifically designed for metal surfaces to ensure proper adhesion and durability. Overall, painting steel angles is a common practice to enhance their appearance and provide additional protection against rust and corrosion.

- Q:How are steel angles cut to specific lengths?

- Steel angles are cut to specific lengths using various cutting tools and techniques. One common method is using a saw, such as a band saw or a circular saw with a metal-cutting blade. The angle is securely clamped or held in place, and the saw blade is guided along the desired cutting line to make a clean and precise cut. Another method is using an abrasive cutting wheel, also known as a cutoff wheel or a grinding disc. This technique is often used for thinner steel angles or when a more precise cut is required. The angle is secured in a vise or a similar holding device, and the cutting wheel is carefully guided along the marked cutting line to remove the excess material. For larger and thicker steel angles, a plasma cutter or an oxy-fuel torch may be used. Both methods involve heating the steel to a high temperature, causing it to melt or oxidize, allowing for a clean and accurate cut. Plasma cutters use a focused jet of ionized gas, while oxy-fuel torches rely on a combination of oxygen and a fuel gas, such as acetylene or propane. In some cases, steel angles can also be cut using more specialized techniques, such as water jet cutting or laser cutting. Water jet cutting involves using a high-pressure stream of water mixed with abrasive particles to erode the steel, while laser cutting utilizes a concentrated laser beam to melt or vaporize the material along the desired cutting path. Regardless of the method used, the key is to ensure the angle is securely held in place and the cutting tool is guided accurately along the marked cutting line. Proper safety precautions, such as wearing protective eyewear and gloves, should always be taken when cutting steel angles to specific lengths.

- Q:Can steel angles be used in conveyor systems or material handling equipment?

- Yes, steel angles can be used in conveyor systems or material handling equipment. Steel angles, also known as angle iron, are commonly used in these applications due to their structural strength and versatility. They can be easily welded, bolted, or riveted together to create various framework structures for conveyors and material handling equipment. Steel angles provide stability, support heavy loads, and can be used to construct frames, supports, and guards for conveyor belts, rollers, chutes, and other components. Additionally, steel angles are available in various sizes and thicknesses to suit different application requirements, making them a popular choice in the construction of conveyor systems and material handling equipment.

- Q:Can steel angles be used in seismic applications?

- Absolutely, seismic applications can definitely make use of steel angles. Thanks to their exceptional strength and ductility, steel angles are widely utilized in seismic applications. Specifically, they are commonly incorporated into the construction of steel moment frames and bracing systems, which are specifically engineered to counteract the lateral forces brought on by seismic events. In regions that are susceptible to earthquakes, steel angles prove to be particularly advantageous in terms of providing structural support and stability. They can be employed as diagonal braces, gusset plates, or stiffeners to enhance the seismic performance of buildings and other structures. Moreover, steel angles boast the added benefit of being easily fabricated and installed, making them an economical choice for seismic applications.

- Q:Can steel angles be used in telecommunications tower constructions?

- Yes, steel angles can be used in telecommunications tower constructions. Steel angles are commonly used in the construction of telecommunications towers due to their strength, durability, and ability to provide structural support. They can be utilized for various purposes such as bracing, cross arms, or mounting equipment, making them an essential component in telecommunications tower construction.

- Q:Can steel angles be used in furniture manufacturing?

- Yes, steel angles can be used in furniture manufacturing. Steel angles are commonly used as structural supports in furniture construction due to their strength and stability. They can be utilized for creating sturdy frames, legs, and corners in various types of furniture such as tables, chairs, and shelving units.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Unequal Steel Angle Mild Hot Rolled Low Carbon Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords