Thermal Insulation Rubber Sheet Rubber Pipe for HVAC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

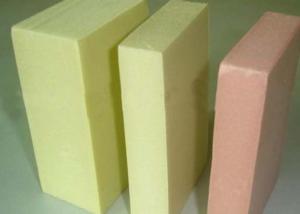

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:Do you have a natural gas hose in the flue?

- Fastening steel pipe scaffold generally by the steel pipe rods, fasteners, base, scaffolding, safety net and other components of steel pipe: generally there are two, an outer diameter of 48mm, wall thickness 3

- Q:How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Mainly for insulation to reduce heat loss. So use a good insulation material insulation. Hope it helps you.

- Q:As for glass wool board and rock wool board, which kind of material is better?

- substitutes of rock wool and glass wool, performance index, the glass wool price is relatively high, less manufacturers.

- Q:How the exterior of the house is made of rock wool color steel sandwich panels

- Construction, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, Erecting outside the scaffolding materials expected ribs of the late section of the dwarf light dog chupu count, template support frame, shelf safety operation technology. Zibu type construction fastener, by the two holes in the diameter of the child is significantly different, the female fastener riveting, two fasteners on the lower cover are steel stamping parts, cover, under the cover with ribs , The upper and lower cover of the middle part of the arc inward convex, the arc-shaped convex surface and the upper and lower cover on both sides of the same cylindrical surface, the child, the female fastener nut on the same size. The fastener is used to build construction scaffolding, building fence, planting greenhouses, etc., can be connected to different diameter pipe, can be rotated angle, wide range of applications, and the fastener weight, bending strength and good steel, , Easy to use.

- Q:Why should the flexible hose be set in the mechanical ventilation system?

- The contents of the special construction plan: engineering overview, preparation basis, construction plan; process technology, safety assurance measures, labor plans, calculation books and related drawings.

- Q:Are foam glass and glass wool the same?

- Not the same.

- Q:Do you need to add any time before the tile tiles before the waterproof material? If the addition of the impact on the wall of the impact of it?

- Caigang sandwich panels as one of the main structure of steel structure, the choice is also equal to the main

- Q:What are the hazards of glass wool to body?

- What are the hazards of glass wool to body?

- Q:A roofer who wants to put a new roof on my mobile home says it will dry out. (We live in the rainiest part of the US)

- I think everyone is misunderstanding your question. I think what you are saying is that your insulation got wet, becasue of your roof leaking. The roofer wants to replace the roof but not the insulation. If your talking about an insulation board under the roof then I think your roofer is right. Just put a new roof on. If you talking about some kind of fiberglass batt insulation then it probably should be replaced.

- Q:on a traditional pitched roof construction,where is heat insulation usually provided?

- On the ceiling.Paper side down to help protect against moister.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Thermal Insulation Rubber Sheet Rubber Pipe for HVAC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords