Textured Used In Underground PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

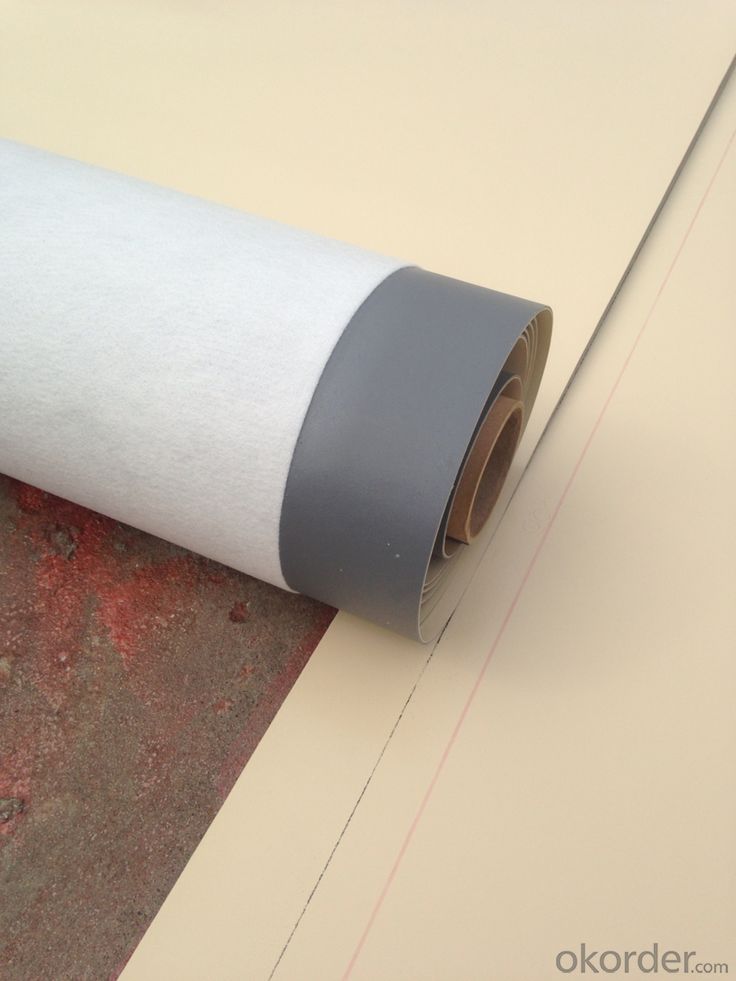

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q:Can a waterproofing membrane be used on stainless steel surfaces?

- Yes, a waterproofing membrane can be used on stainless steel surfaces. The membrane helps to prevent water penetration and protect the stainless steel from corrosion or damage caused by moisture.

- Q:How does a waterproofing membrane perform in areas with heavy foot traffic?

- A protective barrier against moisture and water penetration is the purpose of a waterproofing membrane in various applications. The performance of a waterproofing membrane is crucial in areas with heavy foot traffic. In such areas, the membrane's durability and strength become essential factors. A waterproofing membrane engineered specifically for heavy foot traffic can withstand the constant stress and pressure exerted by people walking, running, or using heavy equipment. Maintaining its integrity and preventing water or moisture from seeping through is one way a waterproofing membrane excels in areas with heavy foot traffic. It acts as a reliable shield, ensuring the underlying structure stays dry and protected. This is particularly important in spaces like balconies, terraces, or concrete walkways where water infiltration can cause structural damage, corrosion, or mold growth. Furthermore, a suitable waterproofing membrane for heavy foot traffic areas should possess excellent abrasion resistance. This means it can endure the friction and wear caused by frequent foot traffic without deteriorating or losing its waterproofing properties. The membrane should resist damage from shoes, heels, or other objects that may come into contact with its surface. Moreover, a waterproofing membrane for heavy foot traffic areas should be slip-resistant to guarantee the safety of individuals walking on it. It should provide sufficient traction and grip, even when wet, to prevent accidents or injuries. This is especially vital in spaces like swimming pool decks or commercial buildings where the risk of slipping is higher. In conclusion, a waterproofing membrane designed for heavy foot traffic areas performs by effectively sealing the surface, preventing water infiltration, and protecting the underlying structure. It should possess durability, strength, abrasion resistance, and slip resistance to ensure optimal performance and safety in areas subjected to heavy foot traffic.

- Q:Can a waterproofing membrane be used on lead surfaces?

- No, a waterproofing membrane cannot be used on lead surfaces as it would not adhere properly and may cause further damage to the lead material.

- Q:Can a waterproofing membrane protect against mold or mildew growth?

- Yes, a waterproofing membrane can help protect against mold or mildew growth. Mold and mildew thrive in damp and moist environments, and a waterproofing membrane creates a barrier that prevents water from seeping into the building structure. By keeping the area dry, it greatly reduces the chances of mold or mildew growth. Additionally, waterproofing membranes often have anti-microbial properties that inhibit the growth of mold and mildew even further. However, it's important to note that while a waterproofing membrane can provide significant protection against mold and mildew, it is not a foolproof solution. Proper ventilation and regular maintenance are also essential to prevent these issues.

- Q:Can waterproofing membranes be used on shower walls?

- Indeed, waterproofing membranes are suitable for application on shower walls. They play a crucial role in shower construction by preventing water leakage and safeguarding adjacent areas from potential harm. These membranes act as a barrier, effectively blocking water infiltration into the shower's structural components. Typically, they are installed behind the tile or other wall coverings, serving as an additional protective layer. Designed to be pliable, long-lasting, and moisture-resistant, waterproofing membranes guarantee the preservation of watertight shower walls and safeguard against any water-related harm.

- Q:Are waterproofing membranes resistant to extreme weather conditions?

- Yes, waterproofing membranes are designed to be highly resistant to extreme weather conditions. They are engineered to withstand heavy rain, snow, high winds, and temperature fluctuations without compromising their effectiveness. They provide a durable barrier against moisture, protecting structures from water damage, leaks, and potential structural issues caused by extreme weather.

- Q:Can a waterproofing membrane be used on concrete block walls?

- Yes, a waterproofing membrane can be used on concrete block walls. Concrete block walls are susceptible to water penetration, which can lead to issues such as mold, mildew, and structural damage. A waterproofing membrane is a protective barrier that is applied to the surface of the concrete block walls to prevent water from seeping through. It acts as a barrier against moisture, creating a watertight seal and preventing water from entering the interior of the walls. This helps to maintain the integrity of the walls and protect against water-related damages. However, it is important to ensure that the waterproofing membrane is properly installed and that any existing cracks or gaps in the concrete block walls are adequately sealed before applying the membrane.

- Q:How does a waterproofing membrane handle structural cracks?

- A waterproofing membrane is designed to handle structural cracks by providing a barrier that prevents water penetration through the cracks. It acts as a protective layer, sealing the cracks and preventing any moisture from seeping into the underlying structure. This helps to maintain the integrity of the waterproofing system and ensures long-term protection against water damage.

- Q:Are waterproofing membranes resistant to thermal expansion?

- Yes, waterproofing membranes are resistant to thermal expansion. Waterproofing membranes are designed to withstand changes in temperature without losing their integrity or functionality. They are made from materials that have excellent thermal stability and low thermal expansion coefficients, which allows them to expand and contract without causing damage or compromising their waterproofing properties. This resistance to thermal expansion is crucial in ensuring that the waterproofing membrane remains effective and durable in various weather conditions, including extreme heat or cold.

- Q:Can a waterproofing membrane be used for a roof?

- Yes, a waterproofing membrane can be used for a roof. Waterproofing membranes are specifically designed to provide a barrier against water penetration, making them an ideal choice for protecting roofs from leaks and water damage. They are durable, flexible, and can be applied to various types of roofs, including flat and sloped surfaces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Textured Used In Underground PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords