TearStop Anti Condensation Felt for steel construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 roll

- Supply Capability:

- 1000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Tear Stop Anti Condensation Felt description

Tear Stop Anti-condensation felt is a kind of anti-cold condensation material which is made of a new type of needle-punched polyester non-woven fabric by special process.

It is widely used in high temperature and humidity workshops, dry goods warehouses, food and drug production workshops with high cleanliness requirements, breeding farms, gymnasiums, aircraft hangars and other metal roofing buildings

It can effectively prevent the occurrence of condensation dripping in metal buildings, play a role in preventing cold condensation dew, heat insulation, noise reduction, energy saving and improving the living environment.

2. Main features of the Tear Stop anti condensation felt

(1) Easy to clean buy using a high-pressure water gun ; 20 years maintenance free

(2) Automatic production, one-time installation

(3) Moisture, mildew, no breeding bacteria

(4) No pollution in production and use link , does not damage the health of construction personnel, will not cause pollution to the surrounding environment

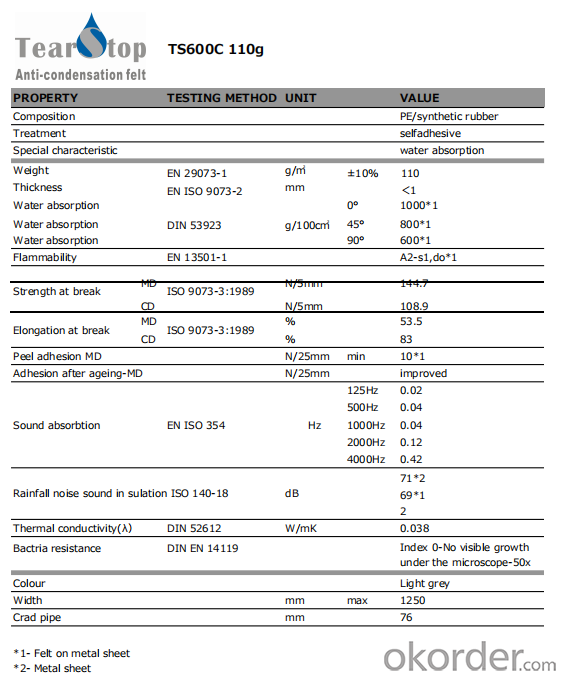

3. Technical Parameters

4. Images of the Tear Stop anti condensation felt

- Q:Bathroom first leveling or do waterproof, what is the difference

- 7. The threshold stone is only decorated, do not mistakenly believe that can hold water. In short, each process have to carefully do not leave a hidden trouble to ensure worry. But the reality of the structure, materials, workers, mutual protection and many other unsatisfactory, so that waterproof is a common problem, perhaps set (overall) bathroom by the factory as a whole production test, on-site assembly will solve this common problem.

- Q:Villa roof leakage what general reasons, what materials to remedy

- Fourth, the roof of a large area of ??leakage or a number of water leakage points, the first by the professionals to check whether the cracks, according to the previous program to deal with the cracks in the roof covered with waterproof membrane, to enhance the waterproof effect, but also And then covered with insulation board, because the height of the insulation board in 20 cm or more, to achieve the protection of waterproof layer and thermal insulation of the double effect. Wall cracks appear seepage, under normal circumstances the professional construction team will use the basket, by the maintenance staff in the external wall construction.

- Q:Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Need to waterproof the external walls, there are several programs. First, directly in the existing external walls of the main surface of the water treatment, the use of technology and materials due to different external finishes and different;

- Q:Roof membrane waterproof construction process, what should be noted that?

- Coil ply attention Paving direction, slope less than 3%, parallel and roof paving, slope greater than 15% or roof vibration, perpendicular to the roof paving. Slope between 3% to 15%, can be parallel to the vertical; membrane waterproof roof slope should not be greater than 25%. The upper and lower layers may not be piled on each other.

- Q:Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- First, rigid (concrete) waterproof roofing SBS membrane should not be painted before the coating of any waterproof coating, otherwise it will damage the bonding strength of the coil and the grassroots.

- Q:I would like to ask how to do in the warm water above,

- I do not do 80% of the warm water, of course, the use of good quality water pipes, waterproof water is generally done in the following to do, if done in the warm tube above will affect the heat of the floating, to warm the following covered with a Layer insulation layer and then covered with warm tube to, and then beat the water to ensure that no leakage. And finally in the above covered with wooden floor or floor tiles.

- Q:What decoration materials, light and water, and the wall, the perfect combination of glass

- Third, the mouth of the mouth, put pressure glue gun Cut the hose tube, fitted with a pointed nozzle, and then according to the size of the gap will be cut by 45 degrees angle. Install the glue gun.

- Q:Waterproof mortar expensive or dry mortar expensive

- Waterproof mortar more expensive. Because waterproof mortar compared to dry mortar, to add another waterproofing agent, emulsifier and other substances. Waterproof mortar regardless of the cost or transport are more cost-effective.

- Q:FRP finished brush on what can be waterproof do not fade

- FRP appearance is the use of gel coat, we do the appearance of glass steel yacht are gel coat, also known as plastic shell, resin gel coat, etc., the color can be customized in the factory, Nanjing DSM company there.

- Q:What is the car material so that the car can be waterproof, in the rain will not leak in?

- ?B. printing, inkjet, photo, screen printing and other technology: refers to the computer will be vector or pixel images into the machine, the machine in accordance with the graphics inkjet or screen technology will color ink printing or screen in a transparent or white base film, And then through the cutting edge along the edge of the pattern; at present most of the manufacturing enterprises (such as motorcycles, electric bicycles, etc.) mass production car stickers are used screen printing process;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TearStop Anti Condensation Felt for steel construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 roll

- Supply Capability:

- 1000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords