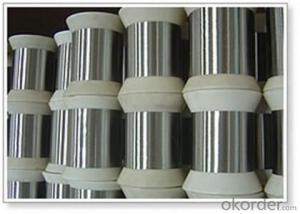

Straight Line Stainless Steel Wire Drawing Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Easy operation

2.High speed&high efficiency

3.Low noisy&production cost

4.PLC control

5.Excellent aftersales service

Place Of Origin: China

Delivery Time: 65 days

Package: according to your requests

Feature: Applicable for continuous drawing and PLC control of frequency transformer drive of high/medium/low carbon steel/alloy steel/stainless steel.

Main technical parameter:

specification | LZ200,LZ 350,LZ 400,LZ450,LZ500,LZ560,LZ600,LZ700 |

Capstan diameter | 200, 350, 400, 450, 500, 560, 600 , 700 |

Drafts | 2-12 |

Max. inlet diameter(mm) | 10 |

Min. outlet diameter(mm) | 0.2 |

speed | According to customers’ requirements |

power | 7.5-90 KW |

capstan | Material is cast steel, coated with tungsten carbide. Surface hardness reaches 60-62HRC. Abrasive resistance is very good. |

Drive system | Adopt 1st or 2nd grade strong narrow V belt; 1st grade strong narrow V belt+ 1st grade hard tooth surface wheel gear with little noise; 1st grade strong narrow V belt+ 1st grade hard tooth surface wheel gear |

wire drawing machine manufacturers with more than 20 years experiences with a high reputation in China.

|

| | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

.

- Q:What are the appliances cleaning equipment

- A steam engine, a steam engine Air conditioning cleaning machine Water heater cleaning machine Water cooler Multi-function sterilizer Geothermal cleaning machine Also not commonly used: suction blower, the hotel oil and smoke machine washing machine, washing machine ultrasonic cleaning machine, keyboard washing machine and so on

- Q:The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- First, the source and composition of the oil pollution should be made clear. In particular, it is clear that it is possible to take medicine against the disease. The oil on general equipment is divided into two categories: lipids and oils. The best way to deal with lipids is by physically removing and chemical decomposition. In the case of oils, the main thing is chemical decomposition. Because you do not know the type and structure of your device, you can only suggest the following: 1, before manual cleaning, the specific chemical decomposition should be arranged so that the cleaning can be twice as effective. According to the source of the oil pollution, do the precautionary setting. For example, it is easier to paste the protective coating on the spot where the oil pollution is frequently occurring. Use special tools and equipment to clean up the oil. Personal sense, the process of decomposition is important. For your reference.

- Q:Is there any molding equipment in the car engine?

- We now have the patent equipment hydrogen carbon removal machine, especially the combustion chamber carbon cleaning cars, clean up three yuan may oxygen sensor at the same time, only for 15 minutes, without having to remove the parts, don't need an oil change

- Q:The heavy oil on the machine should use what cleaning agent to clean up?

- The downstairs brother was right. I'm the one who often USES this oil cleaner, Because it's local, it's clear that it works well. I recommend you to consult..

- Q:Characteristics of cleaning equipment of cleaning equipment

- High pressure water jet cleaning mainly has the following characteristics: (1) selecting the appropriate pressure level, the water jet cleaning will not damage the base of the cleaning equipment. (2) is using ordinary tap water with a high speed washed clean, so it does not pollute the environment, anti-corrosion equipment, won't cause any mechanical damage, can also be removed with chemical cleaning of refractory or cannot dissolve the special scale; (3) after washing, the equipment and parts shall not be cleaned; (4) cleaning parts that are complex in shape and structure, which can be cleaned in a space narrow, complex, hostile and harmful environment; (5) it is easy to achieve mechanization, automation and digital control. (6) save energy, clean efficiency and low cost. Chengdu feng cleaning machine, with its strong technical force and reliable after-sales service protection, the pressure washer in the domestic many areas have a large promotion, cleaning machines are exported to overseas markets, done a good job in the technology field.

- Q:What is suitable for factory cleaning equipment

- Industrial vacuum cleaner is used to collect waste gas, dust and debris from equipment in industrial production, purify workshop environment, and no secondary pollution. High pressure cleaning machine, clean equipment oil pollution, rust stain, and some areas with small and unsanitary areas.

- Q:What is the issue of cleaning equipment? Is there a difference between industrial cleaning equipment and common equipment?

- The highest rated working pressure of the industrial high pressure cleaning machine is much higher than the highest rated working pressure of the commercial high pressure cleaning machine. 2: under the same technical parameters (pressure flow), industrial high pressure cleaner can effectively continuously working time is more than commercial grade high pressure cleaner can effective working hours continuously. 3: under the same technical parameters (pressure flow), industrial high pressure cleaner of the pump head and the whole machine volume is greater than that of commercial grade high pressure cleaner pump head and engine volume. 4: under the same technical parameters (pressure flow), the value of industrial high pressure cleaner and service life is far greater than the value of commercial grade high pressure cleaner and service life. The pump head material of the industrial high pressure cleaning machine must be made of alloy steel, and the pump head of the commercial class high pressure cleaning machine usually USES copper or aluminum. Generally, the price is determined by several parameters. After all, it is more complicated, considering your needs and consulting the manufacturers. The company used in the previous company is the washing equipment made by chengdu power feng, the pre-sale and after-sale service is very good, you can also consult.

- Q:What are the benefits of sanitation

- It's good for the equipment and it's comfortable to watch

- Q:How many kinds of cleaning equipment are there for cleaning companies?

- Other cleaning: sofa machine, air conditioner, steam engine, vacuum suction machine, multi-function washing machine, polishing machine, stone retread machine, etc

- Q:What is the cleaning equipment?

- Cleaning equipment as the name suggests is designed for cleaning machinery and equipment, cleaning equipment play an effective cleaning effect, it reduces the labor cost of cleaning, and also improves the work efficiency and cleanness is indispensable to modern society.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Straight Line Stainless Steel Wire Drawing Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords