Steel Rebar, Deformed Steel Bar, Iron Rods for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Steel rebar, Deformed Steel Bar, Iron Rods for Construction

Product information

1. Produce Standard: GB, AISI, ASTM, SAE, EN, BS, DIN, JIS

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment: Normalized / Annealed / Quenched+Tempered

4. Quality assurance: All order we can received third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product detail

Deformed Steel

1) Product name: Deformed Steel Bar

2) Standard and grade: a) GB1499-98 HRB335,HRB400,HRB500 b)BS4449-1997 GR460

3) Diameter: 8mm; 10mm; 12mm;14mm; 16mm;18mm; 20mm; 22mm; 25mm; 28mm; 30mm; 32mm; 40mm;

4) Length: 9m, 12m

5) Packing: Mill standard export packing in bundles, 2tons/bundle or 2tons/coil.

6) Country of Origin :China

7) Applications:The products are widely used in construction, road, machinery processing, and welding fields.

8)Delivery Time :Within 20 days.

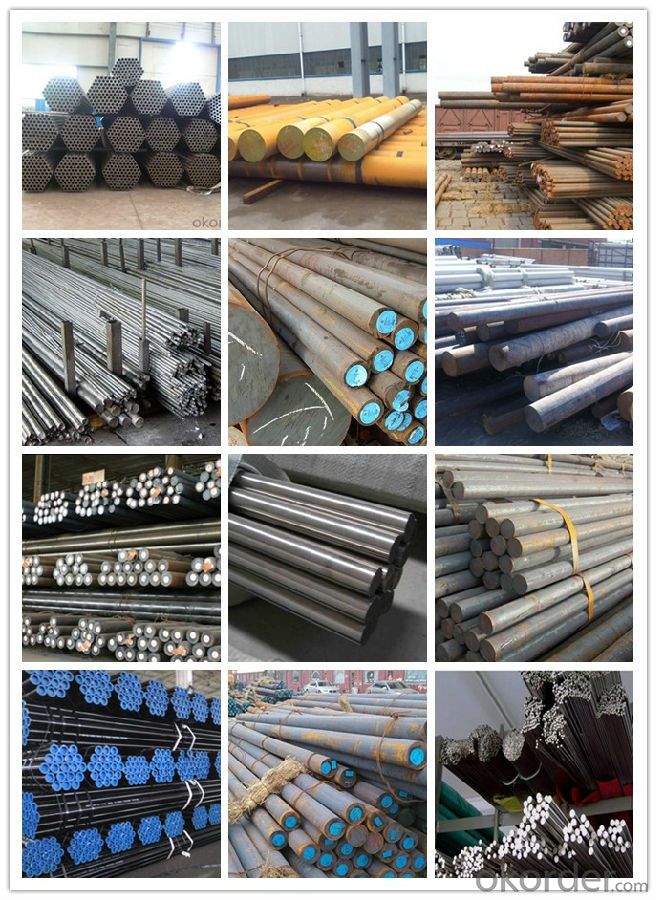

Product show

Work shop

Our Services

* Welcome to contact us with your detailed inquiry, you will be replied within 24 hours.

* You are promised to obtain the best quality, price and service.

* We'd like to provide samples for your confirm.

- Q:How does special steel contribute to reducing product recalls?

- Special steel plays a crucial role in reducing product recalls by offering enhanced durability and strength to various components and parts. Its superior properties, such as corrosion resistance, heat resistance, and high tensile strength, make it less prone to failure or breakage, ensuring the overall reliability and safety of the products. By using special steel in manufacturing processes, companies can mitigate the risk of product defects, resulting in fewer recalls and better customer satisfaction.

- Q:How does special steel contribute to the construction equipment industry?

- Special steel contributes to the construction equipment industry by providing high strength, durability, and resistance to wear and tear. This type of steel is specifically designed to withstand harsh working conditions, such as heavy loads, extreme temperatures, and abrasive materials. Special steel components, such as gears, bearings, and cutting edges, improve the performance and lifespan of construction equipment, enabling them to operate efficiently and reliably. Additionally, special steel alloys offer flexibility in design and manufacturing, allowing for the production of lighter and more fuel-efficient machines, ultimately contributing to increased productivity and cost-effectiveness in the construction industry.

- Q:What are the common quality control measures for special steel?

- Special steel undergoes various quality control measures to ensure its compliance with desired properties and specifications. These measures are as follows: 1. To ensure the required chemical compositions, chemical composition analysis techniques, such as spectrometry, are employed. 2. Mechanical testing, including tensile testing, hardness testing, impact testing, and fatigue testing, is conducted to verify the steel's mechanical properties, such as strength, hardness, toughness, and ductility. 3. Non-destructive testing methods, like ultrasonic testing, magnetic particle testing, and dye penetrant testing, are utilized to detect any internal or surface defects in the steel, ensuring its integrity and reliability. 4. Precise dimensional inspection is carried out to measure critical dimensions, such as length, width, thickness, and diameter, in accordance with customer requirements or industry standards. 5. Surface quality inspection ensures that the steel meets the required surface quality standards by examining it for defects such as cracks, pits, scratches, or unevenness. 6. The effectiveness of the heat treatment process, which includes annealing, quenching, or tempering, is verified through hardness testing or microstructure analysis. 7. Comprehensive documentation and traceability records are maintained to ensure quality consistency and provide a reference for future use or troubleshooting. These records include details of the production process, chemical composition, mechanical properties, and any inspections or tests performed. By implementing these quality control measures, manufacturers can guarantee that special steel meets the required specifications, offering customers high-quality and dependable products for their specific applications.

- Q:What are the main applications of special steel in the power storage industry?

- Special steel has various applications in the power storage industry, primarily in the production of battery components and infrastructure. It is widely utilized in the manufacturing of battery cases, frames, and terminals due to its high strength, corrosion resistance, and electrical conductivity properties. Additionally, special steel is used in the construction of power storage facilities and equipment, such as racks and supports, ensuring durability and reliability of the infrastructure. Overall, the main applications of special steel in the power storage industry revolve around enhancing the performance, longevity, and safety of batteries and power storage systems.

- Q:Can special steel be used for jewelry?

- Yes, special steel can be used for jewelry. Special steel, such as stainless steel or titanium, is often used in jewelry making due to its durability, resistance to tarnish, and hypoallergenic properties. It is commonly used for crafting earrings, necklaces, bracelets, and rings, providing a sleek and contemporary look for those who prefer an alternative to traditional precious metals.

- Q:What are the different types of free-cutting steel?

- There are several different types of free-cutting steel, including leaded steels, sulfurized steels, and phosphorized steels. These types of steels are specifically designed to improve machinability and enhance the cutting performance during manufacturing processes.

- Q:Can special steel be used in mining applications?

- Yes, special steel can be used in mining applications. Special steel alloys are often utilized in mining equipment and machinery due to their high strength, durability, and resistance to wear and corrosion. These properties make them suitable for withstanding the harsh and demanding conditions found in mining operations.

- Q:How is special steel used in the production of cutting tools?

- Special steel is used in the production of cutting tools due to its unique properties that enhance the tool's performance. The high strength and durability of special steel allow cutting tools to withstand high temperatures and pressures, ensuring a longer lifespan. Additionally, special steel's excellent hardness and wear resistance enable cutting tools to maintain sharpness and precision, resulting in efficient and precise cutting operations.

- Q:Can special steel be used in the production of gears?

- Yes, special steel can be used in the production of gears. Special steel is often chosen for gear manufacturing due to its high strength, durability, and resistance to wear and fatigue. It allows for the production of gears that can withstand heavy loads, high speeds, and harsh operating conditions.

- Q:How does special steel perform in cryogenic fatigue resistance?

- Special steel is known for its exceptional performance in cryogenic fatigue resistance. Cryogenic fatigue refers to the deterioration of a material's structural integrity under repeated loading and unloading at extremely low temperatures. Special steel, also known as high-performance or high-strength steel, exhibits superior resistance to cryogenic fatigue compared to conventional steels. The unique composition and microstructure of special steel contribute to its enhanced cryogenic fatigue resistance. Special steels are typically alloyed with elements such as nickel, chromium, and molybdenum, which improve their mechanical properties, including strength and toughness, even at low temperatures. These alloying elements enable the steel to maintain its integrity and resist crack initiation and propagation, which are common failure mechanisms in cryogenic environments. Furthermore, the microstructure of special steel is carefully controlled during the manufacturing process to ensure optimal performance in cryogenic conditions. The fine-grained structure of special steel reduces the susceptibility to fatigue cracks, as it provides a more uniform distribution of stress and strain throughout the material. This helps prevent the formation of localized stress concentrations, which can lead to crack initiation and subsequent failure. In addition to its composition and microstructure, special steel undergoes rigorous testing and quality control measures to ensure its cryogenic fatigue resistance. Various industry standards and specifications exist to evaluate the performance of special steel in cryogenic conditions, such as the ASTM E466 test method. These tests simulate the cyclic loading and unloading that the material may experience in cryogenic environments and provide valuable data on its fatigue life and durability. Overall, special steel demonstrates excellent cryogenic fatigue resistance due to its unique composition, controlled microstructure, and rigorous testing. Its ability to withstand repeated loading and unloading at extremely low temperatures makes it a preferred choice for applications in industries such as aerospace, energy, and cryogenic storage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Rebar, Deformed Steel Bar, Iron Rods for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords