Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. CMAX Steel Frame Formwork Description

CMAX Steel Frame Formwork System is designed to reduce material quantity, with adjustable flexiable sizes of frame, the 140 series steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean.

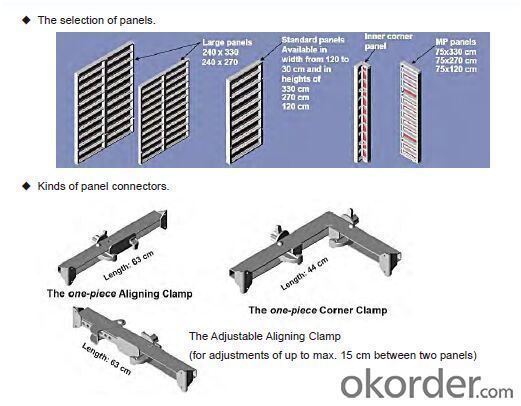

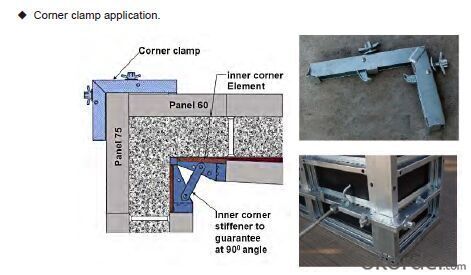

2. Specifications of Steel Frame Formwork

- Max. Concrete pressure: 80KN/m2.

- Hot-dip galvanized steel frame.

- The thickness of plywood is 18mm & the panel is 350px..

- Compatibility with Hunnebeck Manto system due to similar edge profile.

- We can special design according to any requirements.

3. CMAX Steel Frame Formwork Images

4. FAQ of Steel Frame Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q:How does steel frame formwork compare to traditional timber formwork?

- Steel frame formwork is generally considered to be superior to traditional timber formwork in several aspects. Firstly, steel frame formwork offers higher strength and durability, ensuring a longer lifespan and reducing the need for frequent replacements. Additionally, steel frame formwork provides greater stability and resistance to deformation, resulting in more accurate and consistent concrete structures. Moreover, steel frame formwork is typically easier to assemble and disassemble, saving both time and labor costs. Lastly, steel frame formwork offers better reusability, making it a more sustainable and cost-effective option in the long run. Overall, steel frame formwork outperforms traditional timber formwork in terms of strength, durability, stability, ease of use, and sustainability.

- Q:How does steel frame formwork support the weight of concrete?

- Steel frame formwork supports the weight of concrete through its robust and rigid structure. The steel frame is designed to withstand the vertical and horizontal loads exerted by the weight of the concrete during pouring and curing. The formwork system consists of steel beams and columns that are securely connected to form a stable framework. This framework acts as a temporary mold, providing the necessary shape and support for the concrete during the construction process. The steel beams and columns are designed with sufficient strength and stiffness to prevent any deformation or collapse under the weight of the concrete. They are typically manufactured from high-quality steel, which has excellent load-bearing capacity and durability. The steel framework is usually supported by adjustable props or scaffolding to ensure stability and proper alignment during the pouring of the concrete. The props are adjusted to the desired height, allowing the formwork to be level and plumb, ensuring the concrete is poured accurately and evenly. Furthermore, the steel formwork is designed with adequate bracing and tie systems to resist any lateral or horizontal forces that may be exerted by the fluid concrete. These bracings and ties help distribute the load evenly across the formwork, preventing any localized concentration of weight that could lead to failure. Overall, the steel frame formwork system provides a strong and reliable support structure for the weight of concrete. Its robust design, high-quality materials, and proper installation ensure that the formwork can withstand the loads imposed by the concrete, resulting in a safe and successful construction process.

- Q:How does steel frame formwork handle different types of architectural designs?

- Steel frame formwork is a highly versatile construction tool that can handle various types of architectural designs with ease. The strength and flexibility of steel make it suitable for supporting and shaping complex structures, enabling architects to bring their creative visions to life. One way in which steel frame formwork handles different architectural designs is through its adaptability. The steel frames can be easily adjusted and reconfigured to accommodate different shapes and sizes, allowing for the creation of unique and intricate structures. Whether it is curved walls, irregular shapes, or sloping surfaces, steel frame formwork can be customized to meet the specific requirements of any design. Additionally, steel frame formwork offers excellent load-bearing capacity, making it ideal for constructing large and tall structures. This strength allows architects to explore innovative designs that may require significant structural support. From skyscrapers to bridges, steel frame formwork can handle the demands of different architectural designs and ensure the safety and stability of the final construction. Furthermore, steel frame formwork provides precision and accuracy in the construction process. The frames can be fabricated in a controlled environment, ensuring consistent quality and measurements. This precision is crucial in achieving the desired architectural design, as any discrepancies can affect the overall aesthetics and functionality of the structure. In terms of durability, steel is known for its robustness and resistance to various environmental factors. Steel frame formwork can withstand harsh weather conditions, corrosion, and wear and tear, ensuring the longevity of the structure. This durability makes it a reliable choice for architectural designs that aim for both aesthetic appeal and long-term functionality. In conclusion, steel frame formwork is a versatile and reliable construction tool that can handle different types of architectural designs. Its adaptability, strength, precision, and durability enable architects to push the boundaries of creativity and construct unique and complex structures. Whether it is a modern skyscraper, a curvilinear building, or a traditional structure, steel frame formwork provides the necessary support and flexibility to bring architectural visions to reality.

- Q:What is the recommended concrete pouring technique when using steel frame formwork?

- The recommended concrete pouring technique when using steel frame formwork is to pour the concrete in layers, starting from the bottom and working upwards. This helps to ensure a consistent and even distribution of the concrete throughout the formwork, minimizing the risk of voids or air pockets. Additionally, it is important to vibrate the concrete during pouring to remove any trapped air and ensure proper compaction.

- Q:Steel frame wood fire doors and steel doors is a concept

- Steel frame wood fire doors and steel doors is not a concept: filling the former for fire insulation materials; the latter is filled using wooden, paper shell and other environmental protection material interior door.

- Q:Can steel frame formwork be used for both regular and irregular-shaped concrete structures?

- Both regular and irregular-shaped concrete structures can utilize steel frame formwork. This formwork is incredibly versatile and can easily be adjusted and customized to meet any shape or design requirement. The steel frame's strength and rigidity offer ample support and stability, ensuring that the formwork can withstand the pressure exerted by the wet concrete during pouring and curing. Consequently, it is suitable for constructing various types of concrete structures, including those with irregular shapes and complex geometries. Moreover, steel frame formwork allows for efficient and precise construction, enabling intricate designs and architectural features to become a reality. All in all, steel frame formwork is a dependable and adaptable solution for both regular and irregular-shaped concrete structures.

- Q:How does steel frame formwork prevent the formation of concrete cracking during curing?

- Steel frame formwork prevents the formation of concrete cracking during curing by providing a strong and rigid support structure that holds the concrete in place and prevents it from shifting or settling. This ensures that the concrete maintains its intended shape and structural integrity throughout the curing process, minimizing the risk of cracks forming due to uneven curing or excessive stress.

- Q:How does steel frame formwork contribute to the overall strength and stability of a structure?

- Steel frame formwork contributes to the overall strength and stability of a structure by providing a rigid and durable framework that supports the weight of the concrete during construction. This formwork system ensures proper alignment and shape of the concrete structure, preventing any deformation or collapse. Additionally, the steel frame formwork allows for efficient and cost-effective construction as it can be easily assembled, disassembled, and reused for multiple projects.

- Q:What are the different types of edge systems available for steel frame formwork?

- Steel frame formwork offers a variety of edge systems, each with its own advantages and applications. Let's take a look at some of the most common types: 1. L-shaped edge systems: These systems utilize L-shaped steel profiles that are affixed to the formwork panels. Their purpose is to provide a robust and steady edge against which the concrete can be poured, ensuring precise and straight edges. 2. Chamfer edge systems: If you're looking to create beveled edges on the concrete, chamfer edge systems are the way to go. They consist of steel profiles with angled surfaces that are attached to the formwork panels. Chamfer edges are frequently used for decorative and visually appealing finishes. 3. Curved edge systems: When you need curved or rounded concrete edges, curved edge systems are your best bet. These systems typically employ flexible steel profiles that can be easily bent or curved to achieve the desired shape. With curved edge systems, you can achieve smooth and seamless curved edges in the concrete. 4. Corner edge systems: Specifically designed for forming sharp corners in the concrete, corner edge systems feature steel profiles bent at a 90-degree angle to create the corner edge. These systems ensure well-defined and structurally sound concrete corners. 5. Adjustable edge systems: For projects that require flexibility in the formwork, adjustable edge systems come in handy. Typically consisting of modular components, these systems can be easily adjusted to accommodate different formwork configurations and dimensions. They are particularly useful for complex or irregularly shaped structures. Ultimately, the choice of edge system depends on the specific requirements of the construction project, including the desired finish, formwork complexity, and structural considerations.

- Q:What safety precautions should be taken when using steel frame formwork?

- When using steel frame formwork, it is important to ensure the following safety precautions are taken: 1. Properly train all workers on the correct handling and installation of steel frame formwork to avoid accidents and injuries. 2. Wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and steel-toed boots to protect against potential hazards. 3. Inspect the steel frame formwork for any defects or damage before use, and repair or replace any compromised components. 4. Securely anchor the formwork to prevent any movement or collapse during concrete pouring or other construction activities. 5. Regularly inspect and maintain the formwork to ensure its stability and structural integrity. 6. Implement proper fall protection measures such as guardrails, safety nets, or harnesses when working at heights. 7. Communicate and coordinate with other workers on the construction site to ensure everyone is aware of the formwork and any potential risks associated with its use. 8. Follow all manufacturer's instructions and guidelines for the safe use of steel frame formwork. By following these safety precautions, the risk of accidents, injuries, and structural failures can be minimized when using steel frame formwork.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords