Steel Frame Formwork for Light Duty Frame Formwork

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork-Light duty frame formwork

Light duty steel frame of this kind is weighing lightly while bearing high capacity and in some sense it will reduce human cost for customers.

2. Main Features of light duty steel frame formwork

-Simply assemble and disassemble.

-Film faced plywood used to repeat its use with almost 40 times

-Smooth concrete surface to reduce post processing fees.

-Accessories used effectively(such as nail, steel wire, tie rod..).

-Adjustable sizes (1200 steel frame formwork can be adjusted from minimum300mm to maximum 1050mm)

-Easy to move and remove

-Parts used in column steel frame formwork can be used in wall steel frame formwork

3. Light Duty Steel Frame Formwork Images

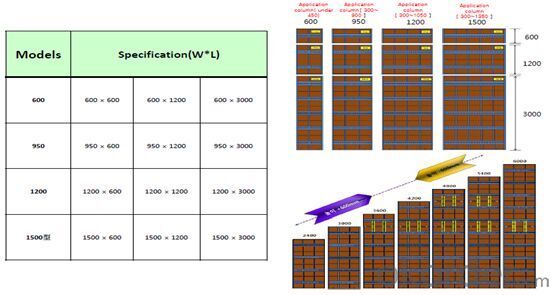

4. Light Duty Steel Frame Formwork Specifications

Column steel frame formwork sizes

5. FAQ of Light Duty Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the Light Duty Steel Frame Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:How does steel frame formwork help in reducing material waste?

- Steel frame formwork helps in reducing material waste in several ways. Firstly, steel frame formwork is highly durable and can be reused multiple times. Unlike traditional wooden formwork, which often needs to be discarded after a few uses, steel formwork can withstand many construction cycles without losing its structural integrity. This means that less material is needed for each construction project, as the same formwork can be used repeatedly. Secondly, steel frame formwork is adjustable and customizable. This allows for precise shaping and sizing of concrete structures, minimizing the need for excessive material usage. With wooden formwork, it is often necessary to cut and shape the wood to fit the desired structure, resulting in wastage of excess material. Steel formwork, on the other hand, can be easily adjusted and reused for different projects, reducing the amount of material that goes to waste. Additionally, steel formwork provides a smooth and even surface finish, reducing the need for additional material to be used for surface treatments. This eliminates the need for plastering or smoothing out uneven surfaces, which would otherwise require additional materials such as plaster or cement. By providing a high-quality finish directly from the formwork, steel frame formwork minimizes the amount of material waste in the form of surface treatments. Overall, steel frame formwork helps in reducing material waste by being reusable, adjustable, and providing a high-quality finish. These characteristics contribute to a more efficient and sustainable construction process, ultimately reducing the overall environmental impact of construction projects.

- Q:What are the common quality assurance procedures for steel frame formwork systems?

- Common quality assurance procedures for steel frame formwork systems include: 1. Inspection of materials: This involves checking the quality and specifications of the steel frames, formwork panels, and other components used in the system. 2. Welding and fabrication inspections: Ensuring that all welding joints are properly executed and inspected for quality, strength, and adherence to standards. 3. Dimensional checks: Verifying that the steel frames and formwork panels are manufactured to the correct dimensions and are within acceptable tolerances. 4. Load testing: Conducting load tests to ensure that the formwork system can withstand the required loads and pressures without failure. 5. Surface treatment inspections: Checking the surface coating or treatment of the steel frames for corrosion resistance and durability. 6. Documentation and record keeping: Maintaining comprehensive records of inspections, tests, and certifications to ensure traceability and compliance with quality standards. 7. Regular maintenance and servicing: Implementing a schedule for routine maintenance and servicing of the formwork system to ensure its ongoing performance and safety.

- Q:Is steel frame formwork suitable for all types of construction projects?

- No, steel frame formwork is not suitable for all types of construction projects. It is commonly used for projects that require high load-bearing capacity and durability, such as commercial buildings, bridges, and high-rise structures. However, for smaller-scale or residential projects, other types of formwork systems like timber or aluminum may be more cost-effective and practical.

- Q:How does steel frame formwork affect the overall structural integrity of a building?

- The overall structural integrity of a building can be significantly impacted by the use of steel frame formwork. To begin with, steel frame formwork offers a robust and rigid support system for the concrete during construction. This guarantees the proper pouring and curing of the concrete, resulting in a structure that is more durable and sturdy. In addition, the use of steel frame formwork enables precise and accurate placement of the concrete, which is crucial for maintaining the building's structural integrity. The formwork system ensures that the concrete is poured in the correct location and shape, thereby preventing any potential weaknesses or irregularities in the structure. Furthermore, steel frame formwork provides exceptional stability and resistance against external forces like wind, earthquakes, and other loads. By acting as reinforcement, the steel framework enhances the overall strength and stability of the building. This is particularly important in areas that are susceptible to seismic activities or extreme weather conditions. Moreover, steel frame formwork exhibits high resistance to corrosion and deterioration, making it a reliable and long-lasting choice for construction. Its durability ensures that the formwork system does not compromise the structural integrity of the building over time. Overall, the utilization of steel frame formwork significantly enhances the structural integrity of a building. It offers a strong support system, precise concrete placement, stability against external forces, and long-term durability. Architects and engineers often prefer steel frame formwork due to its ability to guarantee a safe and sturdy structure, making it an indispensable component in the construction process.

- Q:What are the key components of steel frame formwork?

- The steel panels, connectors, and accessories are the essential elements of a steel frame formwork. The steel panels serve as the primary structural elements of the system, constructed from top-notch steel to ensure rigidity and durability. They come in different sizes and shapes, tailored to meet the specific requirements of each project. These panels are responsible for forming the vertical and horizontal surfaces of the formwork, providing the necessary support and containment for the concrete during pouring and curing. To create a stable framework, connectors are utilized to join the steel panels together. These connectors, available in various types such as clamps, pins, bolts, and wedges, are designed to securely fasten the panels, ensuring their stability during the concrete pouring process. Additionally, connectors facilitate easy assembly and disassembly of the formwork system, making it reusable for multiple projects. In order to enhance functionality and efficiency, a range of accessories are employed in the steel frame formwork. Adjustable props are used to provide additional support and stability, particularly for taller structures. Braces reinforce the formwork, preventing any distortion or movement during concrete pouring. Ties secure the formwork to existing structures or other parts of the formwork system. Wedges are used to tighten and lock the connectors, guaranteeing the stability and integrity of the formwork. Overall, the collaboration of these key components in a steel frame formwork system results in a robust, long-lasting, and adaptable structure that can be utilized repeatedly in various construction projects.

- Q:Are there any limitations on the size and shape of structures that can be constructed using steel frame formwork?

- Yes, there are limitations on the size and shape of structures that can be constructed using steel frame formwork. The primary limitation is the strength and stability of the steel frame itself. While steel is known for its strength and durability, it does have its maximum load capacity. Therefore, when designing structures, engineers and architects must consider the weight and distribution of the load to ensure that it does not exceed the capacity of the steel frame formwork. Additionally, the shape and complexity of the structure can also pose limitations. Steel frame formwork typically consists of standardized panels and components that are assembled to create the desired shape. This means that structures with intricate curves or unconventional shapes may be more challenging to construct using steel frame formwork. In such cases, alternative formwork systems, such as custom-made wooden or flexible formwork, may be more suitable. Moreover, the size of the structure can also affect the feasibility of using steel frame formwork. Large structures may require additional reinforcement and support to ensure stability and prevent deformation. These additional measures can increase the complexity and cost of construction. In summary, while steel frame formwork is a versatile and widely used construction technique, there are limitations on the size and shape of structures that can be constructed using this method. Engineers and architects must carefully consider the load capacity and shape complexity when deciding to use steel frame formwork or exploring alternative formwork systems.

- Q:Is steel frame formwork suitable for both residential and commercial projects?

- Yes, steel frame formwork is suitable for both residential and commercial projects. Steel frame formwork offers several benefits that make it a popular choice for construction projects of all types. Firstly, steel frame formwork is highly durable and can withstand the heavy loads and pressures typically associated with both residential and commercial projects. This ensures that the formwork remains stable and secure throughout the construction process, leading to a high-quality finished product. Additionally, steel frame formwork is versatile and can be easily customized to meet the specific requirements of different projects. Its modular design allows for easy assembly and disassembly, making it ideal for projects that require frequent formwork reconfiguration. Steel frame formwork is also highly adaptable and can be used to create a wide range of structures, from simple residential buildings to complex commercial structures. Moreover, steel frame formwork offers excellent strength-to-weight ratio, which makes it an efficient and cost-effective choice for both residential and commercial projects. Its lightweight nature allows for easy transportation and handling, reducing construction time and labor costs. Furthermore, steel frame formwork is reusable, reducing waste and promoting sustainability in construction practices. In conclusion, steel frame formwork is a suitable choice for both residential and commercial projects due to its durability, versatility, adaptability, strength-to-weight ratio, and cost-effectiveness. Its numerous advantages make it a preferred formwork system for contractors and builders in various construction sectors.

- Q:What is steel frame formwork?

- Steel frame formwork is a type of construction formwork system that uses steel frames as the main component. It is used in concrete construction to create the desired shape and structure of the concrete. The steel frames are designed to provide support and stability during the pouring and curing process of the concrete. They are typically made of high-quality steel, which makes them strong and durable enough to withstand the weight and pressure of the concrete. Steel frame formwork is known for its versatility and flexibility. It can be easily assembled and disassembled, allowing for easy transportation and reusability. This makes it a cost-effective option compared to traditional formwork systems. It also provides a smooth and accurate finish to the concrete structure, ensuring high-quality construction. One of the key advantages of steel frame formwork is its ability to handle complex and intricate shapes. The steel frames can be customized and adjusted to meet the specific requirements of the project, allowing for the construction of unique and innovative designs. This makes it a popular choice for projects that involve curved or irregular structures. Furthermore, steel frame formwork offers excellent safety features. The steel frames are designed to provide stability and prevent any collapse or accidents during the construction process. They can also withstand adverse weather conditions, making them suitable for both indoor and outdoor construction projects. In conclusion, steel frame formwork is a reliable and efficient system used in concrete construction. Its strength, versatility, and safety features make it a preferred choice for many builders and contractors. By using steel frame formwork, construction projects can be completed with precision, efficiency, and durability.

- Q:How does steel frame formwork contribute to the overall cost of a construction project?

- Steel frame formwork can contribute to the overall cost of a construction project in several ways. Firstly, it may require a higher initial investment compared to other types of formwork, such as timber or aluminum. However, this cost is often justified by its durability and reusability, as steel formwork can withstand multiple uses without significant wear and tear. Additionally, steel formwork can help to expedite the construction process by allowing for faster assembly and disassembly, reducing labor costs. Moreover, its strength and stability can minimize the need for additional support structures, saving on material costs. Overall, while steel frame formwork may have a higher upfront cost, its efficiency and longevity can result in long-term cost savings for the construction project.

- Q:Can steel frame formwork be used for commercial buildings?

- Certainly, commercial buildings can make use of steel frame formwork. Steel frame formwork, widely employed in the construction sector, is an adaptable and enduring solution for diverse building types, including commercial edifices. Its remarkable strength and stability enable the development of towering structures and extensive commercial undertakings. Moreover, steel frame formwork exhibits great flexibility, effortlessly tailored to suit the distinctive specifications of various commercial building designs. Furthermore, it delivers a superior finish and can be repeatedly utilized, rendering it an economical option for commercial construction ventures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame Formwork for Light Duty Frame Formwork

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords