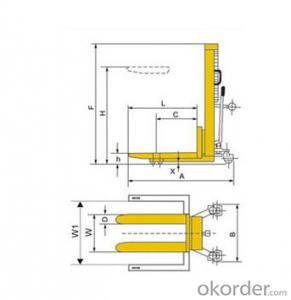

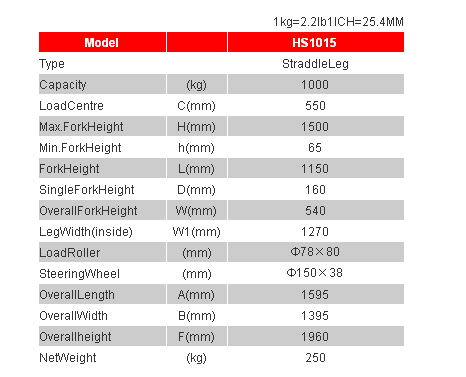

STACKER PRODUCT SERIE - Hand stacker-HS1015 HearvyDutyDesign

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Materialsandspecificationaresubjecttochangewithoutnotice.

HearvyDutyDesign

Uniquetechnologyofquickliftsystem

Compactdesignandstrong,accuratesteelconstruction

TopqualityhydraulicpumpandcylinderwithGermanseals.

Heavyduty1piece"C"sectionforksforgreateststrength.

Topofstrokebypassvalvebuiltin.

ConformstoEN1757-1:2001

All products are granted CE or GS certificates by Rheinland Group. The products are widely used in the field of modern logistic. There are seven product categories and over 2000 sorts. Besides standard products, we also customizes according to your requirements.

We focus on improving our core competitiveness and grasp the trend of upsizing, intelligentizing and environmental friendly. Based on self-developement and innovation, we cooperate with scientific research institution and schools and study new products, technique and craft which are suitable for market.

Stackers and reclaimers were originally manually controlled, with no means of remote control. Modern machines are typically semi-automatic or fully automated, with parameters remotely set. The control system used is typically a programmable logic controller, with a human-machine interface for display, connected to a central control system.

Other than stacking, a stacker has three basic movements:

Luffing: This is vertical movement. Stackers use either a winch mechanism with metal wire, or hydraulic cylinders, generally two. Winch mechanisms are highly reliable compared to hydraulic actuators and remain widely used, particularly in large stackers.

Travelling: The stacker moves on a rail track, which may be broad or narrow gauge, enabling it to move around the stockyard as required. For this purpose, traction motors powered by direct current (DC) are connected by bevel gears to between 12 and 22 wheels. For manual control, all the controls are in a controller's cabin above the boom conveyor or boom. Modern stackers can be controlled remotely.

Slewing: This is rotation of the stacker around its central axis to align or place the stockpile where required. This works mostly by a slew pinion that rotates around a slew base. This type of gear assembly is called a sun and planet gear. The axles may be multiple and are driven by DC-powered axle motors which transmit the torque via bevel or helical gears.

The conveyor belts used in stackers may be made of fabric or metal wire, depending upon the material to be handled. They are driven by pulleys, which in turn are driven by DC motors. The motors and gear are coupled by fluid coupling.

Most stackers are electrically powered by way of a trailing cable. There are basically two types of cable trailing: power cord rotating drum (PCRD) and control cable rotating drum (CCRD). Pendulum adjustments are made to ensure the proper alignment of these cables while the stacker is travelling.

- Q:Where do the elevator motors go?

- Abstract: the shear fork type electric elevator is a special equipment for high altitude operation. The it scissor mechanical structure, make the lifting platform lifting Has high stability, wide operating platform and high bearing capacity, make the work high above the range is bigger, and is suitable for many people work at the same time. It makes high-altitude work more efficient and safer. It is a special equipment for high-altitude operation. Characteristics: the lifting mechanism adopts high strength manganese steel. There is a safety protection device that prevents the elevator from overloading. Safety valve shall be set up to prevent rupture of hydraulic pipe. An emergency reduction device with a power failure. The product is suitable for high-altitude equipment installation, maintenance, etc. According to different requirements can choose different dynamic form (such as: three-phase ac power supply, single-phase ac power supply, dc power and diesel power, etc.), and with manual hydraulic equipment, can be in a power outage or lifting work as usual, no power supply and can add adjustable platform, can extend to the desired location on the length of the platform, so as to improve the work efficiency. It is the ideal of modern high building and equipment, which is necessary for the production of high-altitude safe civilization.

- Q:The ball of the universal milling and lifting platform rolls off, how to install,

- Remove the screw and remove the poles, bearings, and bearings. Find a root (casing pipe diameter and the bottom of the screw thread diameter size, casing Canon and screw axis diameter size), the sleeves on the screw axis, the screw nut screw on the casing; When fully rotating to the casing, remove the casing and the screw nut. Slide to one end of the casing and the screw nut expose about half a circle ball nut (must pay attention to, don't put the ball, or ball will all fall out), with tiny rod or wire, adjust the position of the ball, with one or more of the position of the ball, then fill in falling ball (this step is very important, it is better to have a ball screw pair assembly experience to do); Once you have finished, put the casing on the shaft of the screw. Then turn the nut onto the screw.

- Q:The single fork hydraulic lift platform

- If you don't have a hydraulic lock on the oil circuit, it should be,I hope my answer will help you

- Q:Description of fixed hydraulic elevator

- Set of fixed hydraulic lift cylinder type for the multistage hydraulic cylinder rising, the material of the hydraulic cylinder high strength and good mechanical properties, tower ladder shape frame, make the lifting platform has higher stability. Even at the height of 20 meters, it can feel its superior and stable performance. Application: workshop, hotel, building, mall, station, airport, stadium, etc

- Q:There is no easy way to push the goods when the platform is loaded.

- Yes ah, I know that you need Shanghai luo times Rio tinto, the original poster can combine their actual needs to understand, is upstairs said with race, on the platform with roller

- Q:What can be done when the hydraulic platform is down?

- You can't see your schematic diagram, theoretically do not use hydraulic lock, should balance valve, the frequent switch of hydraulic lock causes jitter and unstable. Shunt valve, speed regulating valve or pressure compensating valve is a common solution to solve synchronization problem. Synchronous diverters are expensive

- Q:How about customizing a tatami mat?

- The hand can use remote control device to control the lifting and lifting of the tatami platform. In the case of a power failure, the tatami can also be used by hand. Make your home life secure and secure! 2, intelligent pressure perfect control system Automatically controlled by the microcomputer chip resistance against the clamp device, when faced with a certain resistance, lift the first stop and recover, prevention effect is better, security more secure; The multi-speed variable speed super-static lift system adopts the high-end super mute multi-speed motor, which is less than 40dB noise. And free control lifting speed and height of couch couch rice, follow one's inclinations, more freedom, more fluid, the machine running below 50 db noise, don't worry about noise environment, the product of science and technology has brought about enjoy the quiet space; 4, smart home interface reserved 5 years is never out of season New embedded wireless WIFI and Zigbee module, compatible with all smart home application interface, can free upgrade in the future of smart home, won't fall behind

- Q:Safety operation of hydraulic platform

- Don't overload your operations; Try to be as special as possible; Try to troubleshoot the professionals if possible. In conclusion, the operation of strict accordance with the operating procedures provided by the manufacturer is the main body of the security guarantee

- Q:Does the fixed hydraulic platform need to submit to the specification requirement

- And then apply for the installation, the installation is done please them again to acceptance inspection, need to producers of products production license, installation and maintenance license, product certification, product warranty card, inspection work more troublesome, need to manufacturers and use of business cooperation. There will be a fee, in some places only provide qualification, ran a few trips, more in some places to spend a lot of it, and later to check every year.

- Q:The hydraulic cylinder with hydraulic platform is changed to whether the cylinder is feasible

- The pressure cylinder is very close, the hydraulic cylinder is not suitable to change to the cylinder, the change is equal to make a new cylinder.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

STACKER PRODUCT SERIE - Hand stacker-HS1015 HearvyDutyDesign

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords