Silt Fence with Pocket/Weed Barrier/Woven Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Silt Fence Description:

A silt fence, also referred to as a filter fence, is a structure composed primarily of geotechnical fabric and that is used as a form of sediment control.These temporary barriers are relatively low in cost, especially when compared to the damages they can prevent. They keep loose soils from traveling into local bodies of water and they also minimize the impact that various forms of development can have on surrounding wildlife.

2. Weed Barrier Fabric Specification:

Weight: 80g/m2~400g/m2;

Width: 0.5m ~6m;

Length: 100m or as required;

3.Weed Barrier Fabric Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

9)Fashionable design,high quality,competitive price

10)Long service life

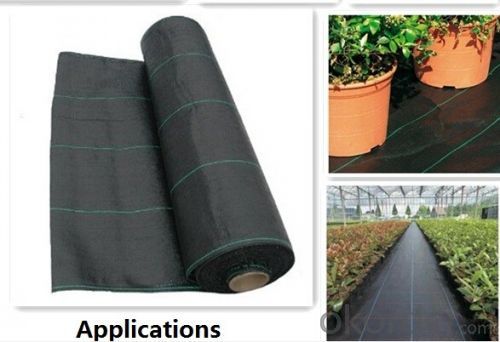

4. Weed Barrier Fabric Usage:

1.Prevent leakage disposal in landfill or waste water or waste dregs disposing field.

2.River bank ,lake dam ,mine remainings ,resevoir ,tunnel ,liquid storage pool(pit ,mine)

3.Preventing leakage in subway ,basement ,tunnel ,hole .

4.Anti-salt leakage in roadbed and other ground sill.

5.The plane direction laying of dam ,the vertical direction laying for ground sill.used in the construction fence and waste material field.

6.Used in ground sill of road ,highway ,railway and waterproof layer of welling clay and wet collapsed loess.

7.Preventing leakage on rooftop.

- Q:What are the specifications for geotextiles in retaining wall construction?

- The specifications for geotextiles in retaining wall construction typically include requirements for strength, permeability, and durability. The geotextile should have sufficient tensile strength to withstand the forces exerted by the retained soil, as well as the ability to allow water to pass through, preventing hydrostatic pressure buildup. It should also possess high puncture resistance and UV stability to ensure long-term performance in outdoor environments. Additionally, the specifications may outline requirements for the geotextile's weight, thickness, and installation methods to ensure proper functionality and compatibility with the specific retaining wall design.

- Q:How do geotextiles help with soil stabilization in geocell applications?

- Geotextiles help with soil stabilization in geocell applications by acting as a barrier between the soil and the geocell system. They prevent the intermixing of soil particles and the migration of fines, providing additional strength and stability to the geocell structure. Additionally, geotextiles enhance drainage and filtration, reducing the risk of soil erosion and improving overall soil performance.

- Q:How are geotextiles recycled?

- Geotextiles are typically recycled through mechanical and thermal processes. Mechanical recycling involves shredding the used geotextiles into smaller pieces, which are then processed into new products such as erosion control blankets or construction materials. Thermal recycling, on the other hand, involves subjecting the geotextiles to high temperatures which break down the material into its constituent components for reuse in other applications. Both methods help reduce waste and promote sustainability in the geotextile industry.

- Q:How do geotextiles help with reinforcement of geogrid retaining walls?

- Geotextiles help with reinforcement of geogrid retaining walls by providing additional strength and stability. They are placed between the geogrid and the backfill soil, acting as a separation layer. Geotextiles prevent the migration of fine particles from the soil into the geogrid, reducing the risk of clogging and maintaining the proper functioning of the wall. Additionally, they distribute the load more evenly across the geogrid, enhancing its tensile strength and overall performance.

- Q:How do geotextiles help with subgrade stabilization in road construction?

- Geotextiles help with subgrade stabilization in road construction by acting as a barrier between the subgrade and the overlying layers of the road. They distribute and reduce the load from the traffic, preventing the subgrade from becoming weak or uneven. Additionally, geotextiles can separate different soil layers, preventing them from mixing and improving the overall stability and strength of the road.

- Q:Are geotextiles resistant to insect infestation?

- Yes, geotextiles are generally resistant to insect infestation. Their synthetic material and tightly woven structure make it difficult for insects to penetrate or nest within the fabric. However, it is important to note that while geotextiles provide a barrier against insects, they are not completely immune to all types of infestation.

- Q:How long do geotextiles last?

- Geotextiles typically have a lifespan of 20 to 50 years, depending on factors such as the type of material used, environmental conditions, and the intensity of use.

- Q:How do geotextiles help in preventing soil compaction?

- Geotextiles help in preventing soil compaction by acting as a barrier between the ground and heavy machinery or vehicles. They distribute the weight more evenly, reducing the pressure on the soil and minimizing compaction. Additionally, geotextiles improve drainage and allow air circulation within the soil, which further helps in preventing compaction.

- Q:How do geotextiles help with soil stabilization in steep slopes?

- Geotextiles help with soil stabilization in steep slopes by providing reinforcement and preventing erosion. When placed on the slope, geotextiles act as a barrier, holding the soil in place and preventing it from sliding or eroding downhill. The geotextiles also allow water to pass through while retaining the soil, reducing the impact of heavy rainfall or water flow on the slope. This helps to maintain the integrity of the slope, preventing landslides and ensuring long-term stability.

- Q:How do geotextiles compare to traditional construction materials?

- Geotextiles are an innovative alternative to traditional construction materials. Unlike traditional materials such as concrete or asphalt, geotextiles offer numerous advantages. They are lightweight, easy to install, and highly flexible, allowing for efficient and cost-effective construction. Geotextiles also provide excellent erosion control, soil stabilization, and drainage capabilities. Furthermore, they are environmentally friendly, as they allow for natural filtration and groundwater recharge. Overall, geotextiles surpass traditional construction materials in terms of versatility, durability, and sustainability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silt Fence with Pocket/Weed Barrier/Woven Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords