Schedule 40 Seamless Carbon Steel Pipe 15CrMo CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

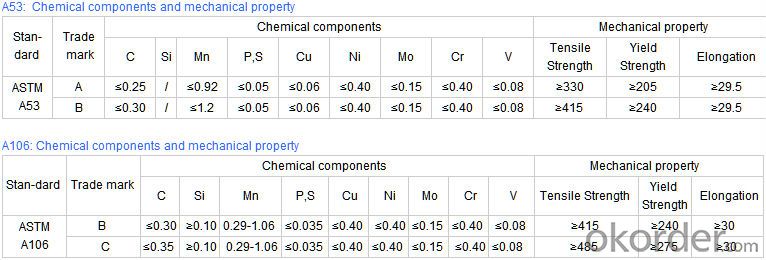

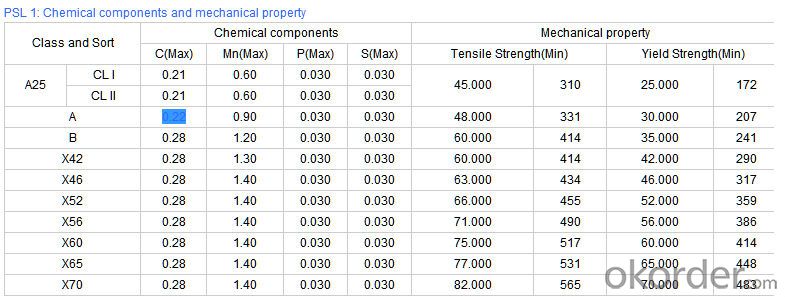

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q:How are steel pipes used in the construction of water supply systems?

- Steel pipes are commonly used in the construction of water supply systems due to their durability, strength, and resistance to corrosion. These pipes are used to transport water from the source to various points of distribution, such as buildings, homes, and industries. Steel pipes are often buried underground or installed above ground, depending on the specific requirements of the project. Additionally, steel pipes can withstand high pressure and are suitable for carrying large volumes of water, making them a reliable choice for water supply systems.

- Q:What are the uses of welded steel pipes?

- It is used to transport water, gas, air, oil and heating steam, and generally lower pressure fluid and other purposes of welded steel pipe. The wall thickness of the steel pipe is divided into ordinary steel pipe and thickened steel pipe. The end of the pipe is divided into non - threaded steel pipe (light pipe) and threaded steel pipe. The specification of steel pipe is expressed by nominal caliber (mm). The nominal diameter is the approximate value of the inner diameter. Usually used in inches, such as 11/2. The welded steel pipe for low pressure fluid transportation is used as the main pipe of galvanized steel pipe for low pressure fluid transportation except for directly conveying fluid

- Q:What are the different types of steel pipe supports for overhead piping?

- Some of the different types of steel pipe supports for overhead piping include clevis hangers, beam clamps, pipe straps, and pipe rollers. Clevis hangers are used to suspend the pipe from a beam or other structural element. Beam clamps attach the pipe to a beam or other support structure. Pipe straps are used to secure the pipe to a wall or other surface. Pipe rollers allow the pipe to move freely while providing support.

- Q:Can steel pipes be used for underground sewer lines?

- Yes, steel pipes can be used for underground sewer lines.

- Q:Can steel pipes be used for nuclear power plants?

- Yes, steel pipes can be used for nuclear power plants. Steel pipes are commonly used in the construction of nuclear power plants for various purposes such as transporting coolant, steam, and other fluids. Steel pipes offer excellent strength, durability, and resistance to high temperatures and pressure, making them suitable for the demanding conditions of nuclear power plants.

- Q:What are the different methods of joining steel pipes together?

- There are multiple techniques for connecting steel pipes, each with its own pros and cons. 1. Welding, the most commonly used method, involves heating and applying pressure to fuse the pipe ends. This creates a robust joint, but it necessitates skilled labor and specialized equipment. 2. Threaded connections involve threading the ends and using fittings to connect the pipes. This method is relatively simple and quick, but it may not be as strong as welding and can be prone to leakage if not sealed properly. 3. Flanged connections involve using flanges and bolts to connect the pipes. This allows for easy disassembly and reassembly, making it suitable for applications that require frequent maintenance. Flanged connections are also highly resistant to leakage. 4. Compression fittings involve compressing a ring or ferrule onto the pipe to create a tight seal. This method is straightforward and does not require heat or welding, making it ideal for applications where heat or sparks are prohibited. 5. Grooved connections involve cutting grooves into the pipe ends and using mechanical couplings to secure them. This method is fast, reliable, and allows for easy assembly and disassembly. Grooved connections are commonly used in fire protection systems. 6. Brazing, similar to welding, involves heating the pipe ends and adding filler material to join them. This method is often used for smaller diameter pipes and provides a strong joint, but it requires a high-temperature torch and skilled labor. Each method has its own advantages and is suitable for different applications. The choice of joining method depends on factors such as required strength, ease of installation, maintenance requirements, and pipe type.

- Q:What are the different types of steel pipe valves?

- There are several types of steel pipe valves, including gate valves, globe valves, ball valves, check valves, and butterfly valves. Each type of valve serves a specific purpose and has its own unique features and applications in various industries.

- Q:Can steel pipes be used for sewage systems?

- Yes, steel pipes can be used for sewage systems. Steel pipes are durable, strong, and resistant to corrosion, making them suitable for carrying sewage. However, they may be more expensive than other materials and require proper coating to prevent rusting.

- Q:What are the different methods of welding steel pipes?

- There are several different methods of welding steel pipes, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW). Each method has its own advantages and is used depending on factors such as the thickness of the pipes, the type of steel being welded, and the desired outcome.

- Q:How do you determine the maximum allowable stress for a steel pipe?

- Several factors need to be taken into account in order to determine the maximum stress that a steel pipe can withstand. The type of steel used in the pipe is of utmost importance, as different types have varying mechanical properties and strengths. Additionally, the dimensions and thickness of the pipe are significant factors in determining its maximum stress capacity. Generally, thicker pipes have higher stress limits compared to thinner ones. Furthermore, it is crucial to consider the operating conditions that the pipe will be exposed to. This includes the temperature, pressure, and the nature of the fluid flowing through the pipe. These conditions can greatly impact the maximum stress that the pipe can tolerate. For instance, high temperatures or corrosive fluids can weaken the steel and reduce its strength. Engineers typically rely on industry standards and codes, such as the ASME Boiler and Pressure Vessel Code and the API standards, to determine the maximum stress limit. These standards provide guidelines and formulas for calculating the maximum stress based on the material properties, dimensions, and operating conditions of the pipe. It is important to emphasize that determining the maximum stress limit is a critical step in ensuring the structural integrity and safety of the steel pipe. It requires a comprehensive understanding of the materials, design considerations, and industry standards. Therefore, it is advisable to seek guidance from experienced engineers or professionals who specialize in piping design and analysis to accurately determine the maximum stress that a steel pipe can withstand.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe 15CrMo CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords