SAE 1010 1018 1020 1022 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SAE 1010 1018 1020 1022 Carbon Steel Round Bar

Products Details

Material | AISI 1010, S10C,1.0330,10# | Round bar | Dia(mm) | Max 700 |

Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12000 | |

Heat treatment | Normalized / Annealed / Quenched / tempered | Plate bar | Thickness(mm) | Max 200 |

Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | Max 3000 | |

Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12000 |

Chemical Composition

Standards: ASTM,JIS,GB,EN(DIN,BS,NF)

Grade | C | Si | Mn | Cr | Ni | Cu |

AIAI 1010 | 0.07~0.13 | ≤0.07 | 0.25~0.50 | ≤0.15 | ≤0.30 | ≤0.25 |

Delivery condition

EAF+LF+VD+(ESR), rolled / forged, annealed / Q+T, black/peeled/turned, UT tested

Application

Carbon steel rod applies to chemical industry, shipping industry,manufacturing industry, construction, decorate industry, electric power, pump shafts, sanitary wares, furniture handles, boiler, high temperature resistant,low temperature resistant,corrosion resistant

Sales Information

Material | High Quality Carbon Structural Steel 1010 |

Size | Diameter:10-700mm Length:6000mm-12000mm |

Origin place | Made In China |

Delivery Condition | Hot rolled, cold drawn, forged |

Surface require | Black, grinding, bright, polish |

Heat treatment | Quenched, Tempered, annealed |

Packing | Seaworthy packing ,wooden case ,carton,woven bag or at client's requires |

Delivery time | According to order’s quantity. |

Trade Term | EXW,FOB,CIF |

Payments | T/T or L/C at sight |

Port | China main Port, such as shanghai, Dalian, Shenzhen port. |

MOQ | 30 Metric Ton |

Main Products

AlloyStructural Steel | 5115, 5120, 5130, 5140, 5145, 4118, 4130, 4135, 4140, 4142, 4320, 4340, 4720, 6150, 8620, E9310,etc. |

Carbon Structural Steel | 1010, 1020, 1035, 1045, 1055, 1065,etc. |

Stainless Steel | 201, 202, 301, 302, 304, 305, 316, 316L, 317, 321, 410, 420, 434, 630,etc. |

Tool Steel | H13, D2, 01, D3,H21, P20, M2,etc. |

Bearing Steel | 52100,8620,4320,9310,440C,M50, etc. |

Spring Steel | 5155,5160,6150,9260,SUP6,SUP7,54SiCr6, etc. |

Products Show

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

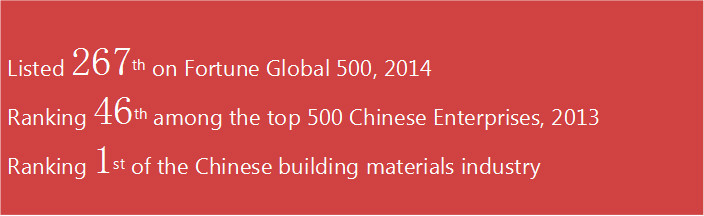

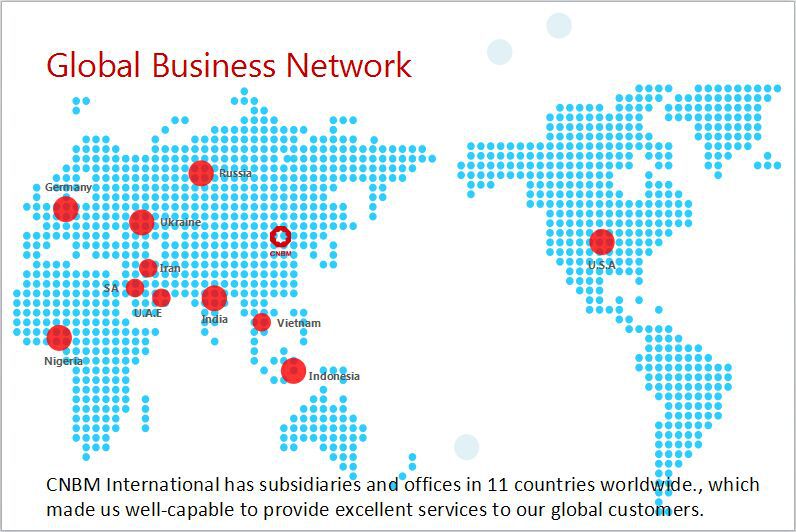

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q:What are the different types of steel round bar alloys used in the automotive industry?

- Different types of steel round bar alloys are utilized in the automotive industry for their distinct properties and applications. 1. Carbon Steel: Carbon steel round bars are extensively employed due to their favorable attributes of strength and toughness. They find use in various automotive components like axles, crankshafts, and gears. 2. Alloy Steel: Alloy steel round bars comprise additional alloying elements such as chromium, nickel, or molybdenum. These alloys enhance the mechanical properties of the steel, rendering it stronger and more durable. Automotive applications like suspension components, drive shafts, and steering components commonly employ alloy steel round bars. 3. Stainless Steel: Automotive applications that demand durability in harsh environments benefit from the highly corrosion-resistant nature of stainless steel round bars. Exhaust systems, fuel tanks, and body parts are frequently made using stainless steel. 4. Tool Steel: Tool steel round bars exhibit high hardness, wear resistance, and toughness. They are predominantly used in the production of automotive tools and dies, like punches, dies, and cutting tools. 5. Bearing Steel: Bearing steel round bars are specifically designed to offer excellent wear resistance and high load-carrying capacity in automotive bearings. These bars possess a high level of hardness and undergo heat treatment to ensure optimal performance. 6. Spring Steel: Automotive suspension systems and other applications that necessitate exceptional elasticity and fatigue resistance utilize spring steel round bars. These bars are capable of enduring repeated stress while maintaining their shape, making them ideal for automotive springs and stabilizer bars. It is crucial to consider the desired properties, performance requirements, and cost considerations of each automotive component when selecting a specific steel alloy.

- Q:What are the different types of threads used for steel round bars?

- The usage of various thread types for steel round bars depends on the specific application and requirements. The most common thread types for steel round bars are as follows: 1. Unified National Coarse (UNC) Thread: This thread type is widely utilized for general-purpose applications and offers a relatively coarse pitch. It is suitable for most common applications that do not demand high strength. 2. Unified National Fine (UNF) Thread: UNF threads have a finer pitch compared to UNC threads and provide better resistance to vibration. They are commonly employed in applications that require a higher level of thread engagement and improved thread performance. 3. Metric Thread: Metric threads are prevalent in countries that adopt the metric system. They are characterized by their pitch, which determines the distance between each thread. Metric threads offer a precise and standardized threading solution for diverse applications. 4. Acme Thread: Acme threads possess a trapezoidal shape and find frequent use in applications necessitating high strength and resistance to wear and tear. They are often employed in heavy-duty machinery like lead screws, jackscrews, and power transmission systems. 5. Buttress Thread: Buttress threads have a triangular shape, with one side perpendicular to the thread axis. This unique design enables them to bear high loads and resist axial forces in a specific direction. Buttress threads are commonly found in applications involving high-pressure fluid flow, such as hydraulic cylinders and pumps. 6. Whitworth Thread: Whitworth threads were extensively used in the past but have become less common in modern times. They have a rounded profile and a coarse pitch. Whitworth threads can still be found in older machinery and equipment. Choosing the appropriate thread type for a specific application is crucial to ensure the proper fit, functionality, and durability of the steel round bar. Factors such as load requirements, environmental conditions, compatibility with mating parts, and industry standards will determine the suitable thread type for a given situation.

- Q:Cold drawn steel wire is a round bar or thread steel in Construction Engineering?

- Cold drawn steel wire should be the same as round steel and thread steel! Their forming process and the meaning of the place used are different, and the quota is also different, cold drawn steel wire is cold drawn steel wire, strictly speaking, there is no mix together.

- Q:What is the difference between hot rolled and cold drawn steel round bars?

- Hot rolled steel round bars undergo the process of heating a steel billet or ingot at a high temperature and subsequently rolling it into the desired shape. This process yields a rougher surface finish and a greater diameter tolerance in comparison to cold drawn steel round bars. The usage of hot rolled bars is frequently found in areas where strength and durability hold significance, such as in construction and manufacturing. On the contrary, cold drawn steel round bars are created by pulling a hot rolled bar through a die at room temperature, leading to a smoother surface finish and tighter diameter tolerances. This procedure also enhances the mechanical properties of the steel, including its strength and hardness. Cold drawn bars are often employed in scenarios where precision and a high-quality surface finish are prerequisites, like in the production of shafts, bolts, and precision components. To summarize, the principal disparities between hot rolled and cold drawn steel round bars encompass the surface finish, diameter tolerance, and mechanical properties. Hot rolled bars bear a rougher surface finish, larger diameter tolerances, and are typically utilized in contexts where strength and durability are paramount. Cold drawn bars possess a smoother surface finish, tighter diameter tolerances, and are commonly employed in situations necessitating precision and a high-quality surface finish.

- Q:How do you prevent rusting of steel round bars?

- To prevent rusting of steel round bars, it is essential to apply protective coatings such as paint, epoxy, or galvanization. Regularly cleaning the bars and keeping them dry, particularly in humid environments, can also help prevent rust formation. Additionally, storing the bars in a controlled indoor environment or using moisture-absorbing materials like silica gel packets can further prevent rusting.

- Q:What are the different welding techniques for steel round bars?

- There are several different welding techniques that can be utilized for steel round bars. Here are some of the most common ones: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW is a popular technique for welding steel round bars. It involves using a consumable electrode coated in flux to create an electric arc between the electrode and the workpiece, melting the base metal and creating a weld. 2. Gas Metal Arc Welding (GMAW): Commonly referred to as MIG (Metal Inert Gas) welding, GMAW is another widely used technique for welding steel round bars. It involves feeding a wire electrode through a welding gun, where it combines with a shielding gas to produce a weld. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuously fed electrode. However, instead of using a solid wire electrode, it uses a tubular electrode filled with flux. This flux helps protect the weld from contamination and provides additional strength. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW is a precise and versatile technique suitable for welding steel round bars. It involves using a non-consumable tungsten electrode to create an arc, while a separate filler rod may be used to add material to the weld. 5. Submerged Arc Welding (SAW): This technique is commonly used for heavy-duty applications, such as welding steel round bars for structural purposes. It involves submerging the arc and the welding zone in a layer of granular flux, which protects the weld from contamination and provides a deep penetration weld. Each of these welding techniques has its advantages and is suitable for specific applications. The choice of technique will depend on factors such as the thickness of the round bars, the required strength of the weld, and the accessibility of the welding site. It is important to carefully consider these factors and select the appropriate welding technique to ensure a strong and durable weld on steel round bars.

- Q:Are steel round bars suitable for high-temperature applications?

- Yes, steel round bars are suitable for high-temperature applications. Steel is known for its excellent strength and heat resistance, making it a reliable choice for various industries that require materials capable of withstanding elevated temperatures. Steel round bars can maintain their structural integrity and mechanical properties even under extreme heat conditions, making them a popular choice for applications such as furnace components, heat exchangers, and high-temperature machinery.

- Q:Can steel round bars be used for making agricultural equipment or machinery?

- Yes, steel round bars can be used for making agricultural equipment or machinery. Steel is a versatile and durable material that is commonly used in the manufacturing of various agricultural equipment and machinery. Steel round bars, in particular, are often utilized for making components such as shafts, axles, and rods that are crucial for the functioning of agricultural machinery. These round bars provide strength, stability, and resistance to wear and tear, making them suitable for heavy-duty applications in the agricultural industry. Additionally, steel is also corrosion-resistant, which is especially important in agriculture where equipment is exposed to harsh environmental conditions. Overall, steel round bars are a reliable choice for constructing agricultural equipment or machinery due to their mechanical properties and ability to withstand the demanding conditions of agricultural operations.

- Q:Are steel round bars resistant to impact?

- In general, steel round bars exhibit resistance against impacts. Steel is renowned for its remarkable strength and durability, rendering it highly impervious to forces and impacts. Additionally, the circular configuration of these bars aids in evenly dispersing the impact, thereby diminishing the likelihood of deformation or fracture. Nevertheless, it is crucial to acknowledge that the steel's resistance to impact may vary depending on the grade and quality, as well as the magnitude and characteristics of the impact force.

- Q:What is the difference between a hot-rolled and a cold-drawn steel round bar?

- The manufacturing process and resulting properties distinguish a hot-rolled steel round bar from a cold-drawn one. To produce hot-rolled bars, a billet or ingot is heated to a high temperature, typically around 1100 to 1300 degrees Celsius, and then rolled into the desired shape and size. This process yields a rougher surface finish and larger tolerances compared to cold-drawn bars. Hot-rolled bars exhibit less precision in dimensions and may contain surface defects such as scale or rust. In contrast, cold-drawn bars undergo manufacturing by pulling a hot-rolled bar through a die at room temperature. This process reduces the diameter and enhances the surface finish, resulting in a smoother and more precise product. Cold-drawing also improves the mechanical properties of the steel, including increased strength, hardness, and improved surface quality. The cold-drawing process provides closer dimensional tolerances, making cold-drawn bars suitable for applications that demand higher precision. In conclusion, the distinction between hot-rolled and cold-drawn steel round bars lies in the manufacturing process, resulting in differences in surface finish, dimensional tolerances, and mechanical properties. Hot-rolled bars are produced at high temperatures, possess a rougher surface, and have larger tolerances. On the other hand, cold-drawn bars are manufactured at room temperature, exhibit a smoother surface, closer dimensional tolerances, and enhanced mechanical properties. The choice between the two depends on specific application requirements and the desired characteristics of the final product.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SAE 1010 1018 1020 1022 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords