Round Cans Automatic Production Line for Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Round Cans Automatic Production Line for Packaging

1. Product Description:

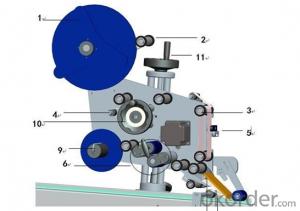

We specialize in the development and manufacture of canning equipment sales of high-tech private enterprises. With mature technology and a strong new product development capability, we make a great effort to the development of energy-efficient in the canning industry. After years of unremitting efforts, has been formed from can body making equipment to cans lids precision molds several series of products. Leading products for 1-18 liter cans production line: 5-25 l turnbuckle barrel (convenience barrels) production line; necking barrels, drums straight bulging tendons equipment; all kinds of tanks, cookie jars, cans and other technology production lines.

2. Product Features:

1) With single nozzle for compound spray, easy to adjust the film volume. 2) System for variable lower chuck speed control by an inverter is available on request. 3) Easy for can size change over. 4) Drying oven equipped with electric (resistance) heating system.

3. Product Parameters:

Model | GT22B |

Capacity | Max.60 ends/min |

Range of Can Diameter | Max.310mm |

Power | 18KW |

Weight | 2000kg |

Dimensions | 1000*2400*2900mm |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

5. Product Pictures:

- Q:Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Ha ha, as you say, TV factories are closed down, every household has a TV, but every day there will be a lot of people buy tv.

- Q:What are the main functions of packaging machinery and equipment?

- Sealing and other major operations, and related processes before and after,

- Q:What are the packaging machines that use temperature control watches?

- A lot of heating machines have to use thermostat

- Q:What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q:The role of food packaging machinery

- 3) to achieve manual packaging can not achieve the operation, some packaging operations, such as vacuum packaging, inflatable packaging, body packing, isobaric filling, etc., are manual packaging can not be achieved, can only be achieved by mechanical packaging.(4) can reduce labor intensity, improve the working conditions of the labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease. Carton folding machine(5) in favor of labor protection for some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the cost of packing and save the storage and transportation expenses. It can reduce the volume and reduce the packing cost by compressing and packing the loose products, such as cotton, tobacco leaf, silk and hemp. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.(7) ensure product health of certain products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.

- Q:The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q:Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q:Bread packing machine Product features

- Product features1. double frequency control, bag length is cut, no need to adjust the empty walk, one step in place, save time and save the film.2. man-machine interface, parameter setting is convenient and quick.3. fault diagnosis function, clear failure display.

- Q:Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Well, yesBut the vacuum packaging machines used for different product sizes are different

- Q:Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you are the original producers, can consider to do the initial stage through the middle of the exporter, first ensure that factory production product quality clearance, production procedures and quality control documents pass, in order to gradually establish its own customer base.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Round Cans Automatic Production Line for Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords