Round Bars Manufacturer with Standard High Quality

- Loading Port:

- Hai Kou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 1000900 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

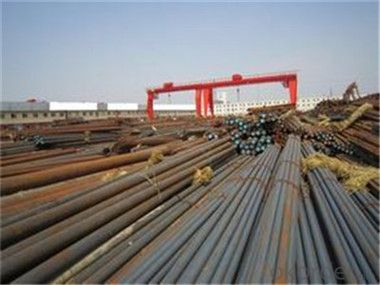

Description of steel round bar:

Diamater:Ø12mm-Ø650mm

Length: standard 6m,9m,12m, If you need special lengths,please tell us.

Festures of steel round bar:

Inspection: 100% UT test, mill test certificate, third party inspection such as SGS,BV etc.

Packing: In bundle, tied by steel straps, covered with protecting film. Use wooden box, filled with foam to keep the surface from damaging ,scratches,crash etc.

Specifications of steel round bar:

Mainly used for engineering component, forging industries, foundation bolt, shafting etc

We also stock RINL make rounds from 16mm to 80mm in all the available grades

We also take special orders in EN8, EN9 or any other equivalent grade with specific dimensional requirements.The data given above in chart are indicative. Actual results may vary.

Images of steel round bar:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:How are steel round bars classified based on their shape?

- Steel round bars are classified based on their shape as either hot-rolled or cold-drawn round bars.

- Q:What is the corrosion resistance of steel round bars?

- The corrosion resistance of steel round bars depends on the type of steel and the environmental conditions they are exposed to. Generally, stainless steel round bars offer excellent corrosion resistance due to the presence of chromium, which forms a protective oxide layer on the surface of the steel. This oxide layer acts as a barrier, preventing further corrosion from occurring. However, carbon steel round bars are more susceptible to corrosion, especially in environments with high moisture or exposure to corrosive substances. In these cases, additional protective measures such as coatings or galvanizing may be required to enhance their corrosion resistance. It's important to note that the performance of steel round bars in corrosive environments also depends on various factors like temperature, pH level, and the presence of other elements or chemicals. Therefore, it is recommended to consider the specific application and consult with corrosion experts to determine the most suitable steel grade and corrosion protection measures for your needs.

- Q:Can steel round bars be used for making conveyor belts?

- No, steel round bars cannot be used for making conveyor belts. Conveyor belts are typically made from materials like rubber or fabric, which provide flexibility and durability necessary for their function. Steel round bars are rigid and not suitable for this purpose.

- Q:What is the difference between a hot rolled and a precision ground steel round bar?

- The main difference between a hot rolled and a precision ground steel round bar is the manufacturing process and the resulting surface finish. Hot rolled steel round bars are made by heating a steel billet until it is soft enough to be formed into a round shape, then rolling it through a series of rollers to achieve the desired diameter. This process creates a rougher surface finish and can result in slight variations in diameter along the length of the bar. On the other hand, precision ground steel round bars are made by starting with a hot rolled bar and then subjecting it to additional grinding or machining processes to achieve a precise diameter and a smooth, consistent surface finish. This extra processing ensures that the bar has a more uniform size and a finer surface texture, making it suitable for applications that require tight tolerances and a polished appearance. Overall, the choice between a hot rolled and a precision ground steel round bar depends on the specific requirements of the application. Hot rolled bars are generally more cost-effective and suitable for less demanding applications, while precision ground bars are preferred for precision machining and high-performance applications.

- Q:How are steel round bars used in the oil and gas industry?

- Steel round bars are widely used in the oil and gas industry for various applications. One of the main uses of steel round bars is in drilling operations. They are used to manufacture drill bits and drill collars, which are essential components of drilling equipment. These drill bits and collars are subjected to high levels of stress and wear during drilling, and steel round bars provide the necessary strength and durability to withstand these conditions. Additionally, steel round bars are used in the construction of oil and gas pipelines. These pipelines are used for the transportation of crude oil, natural gas, and other petroleum products over long distances. Steel round bars are used to manufacture the pipes, ensuring that they have the necessary strength and resistance to corrosion to withstand the harsh operating conditions. Steel round bars also find applications in the construction of oil and gas storage tanks and pressure vessels. These tanks and vessels are used to store and transport petroleum products and gases under high pressure. Steel round bars provide the required structural integrity and strength to ensure the safe storage and transportation of these substances. Furthermore, steel round bars are used in the fabrication of various other equipment used in the oil and gas industry, such as valves, fittings, pumps, and compressors. These components are crucial for the efficient and safe operation of oil and gas production facilities. In summary, steel round bars play a vital role in the oil and gas industry. They are used in drilling operations, pipeline construction, storage tank fabrication, and the manufacturing of various equipment. Their strength, durability, and resistance to corrosion make them ideal for these demanding applications, ensuring the efficient and safe extraction, transportation, and storage of oil and gas.

- Q:How do steel round bars compare to aluminum round bars?

- Steel round bars and aluminum round bars have several key differences in terms of their properties and applications. Strength and durability: Steel round bars are generally stronger and more durable than aluminum round bars. Steel has a higher tensile strength and can withstand higher loads and stresses compared to aluminum. This makes steel round bars suitable for heavy-duty applications where strength and durability are critical, such as construction projects or manufacturing machinery. Aluminum round bars, on the other hand, are less strong and more prone to bending or breaking under heavy loads, so they are typically used in lighter applications or where weight savings are important. Weight: Aluminum round bars are significantly lighter than steel round bars. This makes aluminum a popular choice in industries where weight is a crucial factor, such as aerospace or automotive manufacturing. The lightweight nature of aluminum round bars also makes them easier to handle and transport. Corrosion resistance: Aluminum round bars have excellent corrosion resistance due to the formation of a protective oxide layer on their surface. This oxide layer acts as a barrier, preventing further corrosion and making aluminum ideal for outdoor applications or in environments with high humidity or exposure to chemicals. Steel round bars, on the other hand, are more prone to rust and corrosion, so they require protective coatings or treatments to enhance their resistance to corrosion. Cost: Steel round bars are generally more cost-effective compared to aluminum round bars. Steel is a widely available and commonly used material, making it more affordable in most cases. Aluminum, on the other hand, is more expensive due to its production process and the higher energy requirements involved. Thermal conductivity: Aluminum round bars have excellent thermal conductivity, meaning they can efficiently transfer heat. This makes them suitable for applications where heat dissipation is crucial, such as heat sinks or electrical conductors. Steel round bars, while conducting heat to some extent, have lower thermal conductivity compared to aluminum. In summary, steel round bars are stronger, more durable, and cost-effective, making them suitable for heavy-duty applications. Aluminum round bars, on the other hand, are lighter, have excellent corrosion resistance, and superior thermal conductivity, making them ideal for lightweight applications and industries where weight savings or heat dissipation are critical. Ultimately, the choice between steel and aluminum round bars depends on the specific requirements of the application.

- Q:What is the difference between a turned and a ground steel round bar?

- Two distinct types of steel bars, a turned steel round bar and a ground steel round bar, have undergone different manufacturing procedures. To create a turned steel round bar, a cylindrical steel rod is rotated against a cutting tool, which eliminates material from the bar's surface to achieve the desired dimensions and finish. This process enhances the bar's dimensional accuracy and smoothness. Turned steel round bars find common usage in precision machining or automotive components that necessitate tight tolerances and a smooth surface finish. Conversely, a ground steel round bar is manufactured by passing a turned steel round bar through a grinding machine. This machine uses an abrasive wheel to eliminate any surface imperfections or irregularities from the bar. The grinding process ensures that the bar maintains a consistent diameter and a smooth, polished surface. Ground steel round bars often find application in aerospace components or hydraulic cylinders that demand a high level of precision and surface finish. In conclusion, the primary distinction between a turned and a ground steel round bar lies in the manufacturing processes they undergo. While turned bars are created by cutting material from the surface, ground bars are refined by grinding to achieve superior dimensional accuracy and surface smoothness. The selection between turned and ground steel round bars is contingent upon the specific requirements of the application and the desired level of precision and surface finish.

- Q:What are the different grades of heat-treated steel round bars?

- There are several different grades of heat-treated steel round bars, each offering specific properties and characteristics. Some of the common grades include: 1. 4140: This grade of heat-treated steel round bar is known for its high strength and toughness. It has excellent wear resistance, good machinability, and can be easily heat treated to enhance its hardness and strength. 2. 4340: Heat-treated steel round bars of this grade are known for their high tensile strength, toughness, and fatigue resistance. They are commonly used in applications that require high strength and durability, such as aerospace and automotive industries. 3. 8620: This grade of heat-treated steel round bar is characterized by its case hardening properties. It has good core strength, excellent toughness, and is often used in applications that require high wear resistance, such as gears, shafts, and pins. 4. 52100: Heat-treated steel round bars of this grade are widely used in bearing applications due to their excellent hardness, wear resistance, and high fatigue strength. They are specially designed to withstand heavy loads and provide long-lasting performance. 5. 1045: This grade of heat-treated steel round bar is known for its medium carbon content, providing good strength and impact resistance. It is commonly used in applications that require moderate strength and toughness, such as shafts, axles, and machinery parts. These are just a few examples of the different grades of heat-treated steel round bars available in the market. The choice of grade depends on the specific requirements of the application, such as strength, hardness, toughness, and wear resistance. It is important to consult with a knowledgeable professional to determine the most suitable grade for your particular needs.

- Q:How do you prevent steel round bars from rusting during transportation?

- To prevent steel round bars from rusting during transportation, there are several effective measures that can be taken. 1. Proper packaging: The first step is to ensure that the steel round bars are properly packaged. They should be securely wrapped and sealed in a moisture-resistant packaging material such as plastic or shrink wrap. This will create a barrier against moisture and prevent direct contact with air. 2. Desiccants: Including desiccants, such as silica gel packets or moisture-absorbing clay, inside the packaging can help in absorbing any moisture that may be present. These desiccants will help to maintain a dry environment around the steel bars, reducing the chances of rust formation. 3. VCI (Volatile Corrosion Inhibitor) packaging: VCI packaging is an effective method to prevent rust during transportation. VCI materials release a protective vapor that forms a thin protective layer on the steel surface, inhibiting corrosion. VCI films or papers can be used to wrap the steel round bars, providing a long-lasting rust protection. 4. Proper storage conditions: During transportation, it is important to store the steel round bars in a dry and well-ventilated environment. Avoid exposing them to rain, humidity, or extreme temperature fluctuations. If possible, store them in a covered and climate-controlled area to minimize the risk of rust formation. 5. Regular inspection and maintenance: Regularly inspect the steel round bars during transportation to ensure that the packaging remains intact and no moisture has seeped in. If any damage or signs of moisture are detected, immediate action should be taken to rectify the issue and prevent rust from spreading. By implementing these preventive measures, the risk of rust formation on steel round bars during transportation can be significantly reduced, ensuring that they reach their destination in optimal condition.

- Q:How are steel round bars used in the manufacturing of agricultural machinery?

- Steel round bars are commonly used in the manufacturing of agricultural machinery as they provide strength, durability, and flexibility. These bars are often used to construct various components such as axles, shafts, and pins, which play a crucial role in supporting and transmitting power within the machinery. The high tensile strength of steel round bars allows them to handle heavy loads and withstand harsh operating conditions, ensuring the reliability and longevity of the agricultural equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Round Bars Manufacturer with Standard High Quality

- Loading Port:

- Hai Kou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 1000900 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords