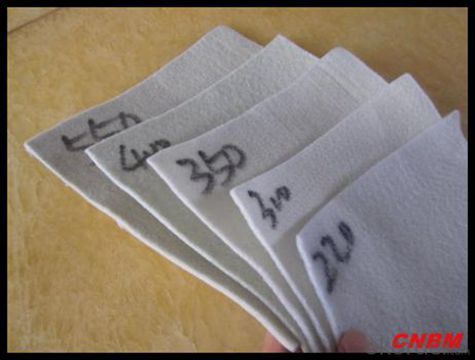

Road Construction Short Geotextile Fabric with Highest Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

Filament Spunbond Nonwoven Geotextile Description:

Made from virgin PET(polyester)chips,the continuous filament was extruded from

PET chip by machine directly by spunbond process,and then punch together to

get the stable 3D with higher strength fabric.So it has high strength, good creep

property excellent and erosion resistance,aging-resistance and heat resistance.

Filament Spunbond Nonwoven Geotextile Property:

Good creep property and hydraulics property,resistance to corrosion,

excellent anti-aging and heat-resistance quality.

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:What are the factors to consider when selecting geotextiles for embankment stabilization?

- When selecting geotextiles for embankment stabilization, several factors need to be considered. These include the type and strength of the geotextile, its permeability and filtration properties, the soil conditions, the slope angle of the embankment, and the expected loads and stresses on the structure. Additionally, factors such as installation and maintenance requirements, cost-effectiveness, and the environmental impact of the geotextile should also be taken into account. Overall, a comprehensive assessment of these factors is essential to ensure the optimal selection of geotextiles for embankment stabilization.

- Q:Will you master knitting reinforced geotextile H and reinforced geotextile What is the difference? In addition, how to distinguish between spunbond and weaving in reinforced geotextiles? More

- Texture and material ratio is different ah.

- Q:How are geotextiles used in geotechnical engineering?

- Geotextiles are commonly used in geotechnical engineering to provide reinforcement, filtration, separation, and drainage in various construction projects. These permeable fabrics are placed within soil or rock structures to enhance their performance, prevent soil erosion, improve stability, and control water flow. Geotextiles are especially useful in road construction, embankments, retaining walls, landfills, and coastal engineering, as they offer cost-effective solutions and contribute to the sustainability and longevity of these structures.

- Q:How do geotextiles enhance the performance of geocells?

- Geotextiles enhance the performance of geocells by acting as a separation and filtration layer between the soil or aggregate fill and the geocell walls. They prevent the migration of fine particles into the geocell structure, improving its overall stability and load-bearing capacity. Geotextiles also provide reinforcement and confinement to the infill material, minimizing lateral spreading and improving the geocell's structural integrity.

- Q:What are the cost considerations for geotextile applications?

- The cost considerations for geotextile applications include the initial cost of the geotextile material, installation costs, maintenance and replacement costs, and the potential long-term cost savings. Additionally, the type and quality of the geotextile, site conditions, and project specifications can also impact the overall cost of geotextile applications.

- Q:what do you mean nonwoven geotextiles ???

- please refer the folowing url to know all the details about non woven geo textiles

- Q:How do geotextiles contribute to soil drainage?

- Geotextiles contribute to soil drainage by providing a permeable layer that allows water to pass through while preventing soil particles from clogging or compacting the drainage system. This helps to improve the overall drainage capacity of the soil by promoting the efficient flow of water, reducing the risk of waterlogging, and enhancing the stability and longevity of the soil structure.

- Q:What are the specifications for geotextiles in pond liner projects?

- The specifications for geotextiles in pond liner projects typically include factors such as weight, tensile strength, permeability, and puncture resistance. The geotextile should be heavy enough to provide sufficient protection against punctures and tears, while also allowing for water to pass through and prevent buildup on the liner. It should have high tensile strength to withstand the stresses of installation and long-term use. Additionally, the geotextile should meet industry standards and regulations for quality and durability in pond liner applications.

- Q:How do geotextiles help with ground reinforcement?

- Geotextiles help with ground reinforcement by providing a stable and durable layer that helps distribute load, reduce soil erosion, and improve soil stability. They prevent the mixing of different soil layers, improve drainage, and enhance the overall strength and integrity of the ground.

- Q:What is geotextile cloth?

- Geogrid, geotextile, geomembrane manufacturers, specializing in the production

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Road Construction Short Geotextile Fabric with Highest Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords