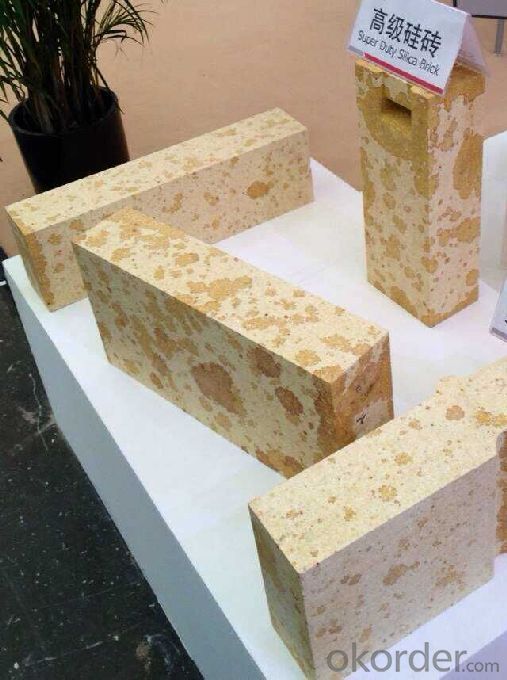

Refractory Light Weight Silica Brick 94A

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

CMAX brand Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Features of Refractory silica bricks for Glass Kiln:

1. high volume density of 2.34 g/cm3

2. high SiO2 content of 96%

3. low iron content of 0.8%

4. low melting point of 5%

Applications of Refractory silica bricks for Glass Kiln:

Because of the high temperature resistant performance significantly, long service life characteristics (as long as more than eight years) of refractory silica brick for Glass Kiln, it can significantly improve the quality of glass, so the refractory silica bricks are widely used in all kinds of glass furnace melting department, regenerator and other important parts.

Physical and chemical index of refractory silica bricks for glass kiln:

Item Brand | CMAX-96A | CMAX-96B | ||

SiO2 % ≥ | 96 | 96 | ||

Al2O3+2(K2O+Na2O) % ≤ | 0.5 | |||

Fe2O3 % ≤ | 0.8 | 1 | ||

Refractoriness °C ≥ | 1710 | 1710.0 | ||

0.2MPa Refractoriness under load °C ≥ | 1680 | 1670 | ||

Apparent porosity % ≤ | Brick with weight no less than 20kg | 20 | 20 | |

rick with weight less than 20kg | 22 | 22 | ||

CS MPa ≥ | 35 | 35 | ||

Bulk desity g/cm3 ≤ | 2.34 | 2.34 | ||

Starndard Size:

230*114*64mm

230*114*76mm

- Q:Refractory factory grinding brick dust harmful to the body?

- Inhalation of this dust can affect people's respiratory tract for a long time

- Q:What is refractory brick?

- Capability1. Refractory brick is also known as firebrick. It is faint?yellow or brownish. Refractory brick with 770 ℃ at high temperatures is called for short firebrick. It is mainly used for building and smelting furnace. It is a refractory material made by fring refractory clay or other refractory material.

- Q:What is fire retardant coating mainly used for?

- Fire retardant coating is a coating which is applied to the surface of buildings and structures and can form a protective layer of fire retardancy and thermal insulation. It can reduce the flammability of the coated materials and block the rapid spread of fire so as to improve fire endurance of the coated materials. Features of fire retardant coating: (1) Fire retardant coating itself has a flame-retardancy or non-inflammability, and it can prevent the protected substrate from direct contact with the air, and delay ignition and reduce the burning speed of the objects. (2) In addition to flame retardancy or non-inflammability, the fire retardant coating itself has a a low thermal conductivity, which can delay the transfer of flame temperature to the substrate to be protected. (3) When heating, fire retardant coating decomposes non-combustible inert gas to dilute the combustible gas decomposed by the protected, making it difficult to burn or slow down the burning rate. (4) Fire retardant coating containing nitrogen will decomposite NO, NH3 and other basic groups, which compound with the organic radicals and interrupt the chain reaction so as to reduce the temperature. (5) intumescent fire retardant coating will expand and foam when heating, and form a carbon foam insulation to block the protected objects, thus delaying the transmission of heat to the substrate.

- Q:Classification of porosities in refractories and their effects on properties

- The pores in refractory include open pores, through pores and closed pores.

- Q:Is fireclay poisonous?

- Refractory materials are typically oxides, alumina, magnesium oxide and aluminate cement and etc, which are non-toxic.

- Q:What a blast furnace refractories generally?

- Common refractories often use silica?brick, semi-silica brick, fireclay brick, high alumina brick, magnesia brick, etc. special materials often used are AZS brick, corundum brick, directly bonded magnesia-chrome brick, carborundum brick, silicon nitride bonded silicon carbide bricks, nitrides, silicides, sulfides, borides, carbides and other non-oxide refractory materials; calcium oxide, chromium oxide, aluminum oxide, magnesium oxide, beryllium oxide refractory insulating refractory frequently used. material diatomite products, asbestos products, insulation boards. monolithic refractories have fettling frequently used, refractory ramming mixes, refractory castable, fire-resistant plastic, refractory clay, refractory gunning refractory projection material, refractory coatings, lightweight refractory castable, stemming etc.

- Q:What is the role of the vermiculite fireproof material?

- The vermiculite fireproof slate is widely applied to construction, shipbuilding, metallurgy, electric power, aerospace and other fields by foreign countries. Vermiculite slate can be applied to furniture, firewall, ceiling, and can be used in the fire fighting access, coated steel, coated pipeline, real flame fireplace in the lining board, wall partition. It is characterized by non combustible, non melting, resistance to high temperature; permanent thermal insulation; sound insulation, non-toxic, smoke-free, green environmental protection; resistance to impact, good dimensional stability and durability of the excellent anti fungal infestation. It can be sawed, nailed, planed, drilled, it can be easily installed and constructed.

- Q:What are included in wall fireproofing material?

- External wall thermal insulation materials are divided into A and B according to combustion level. Grade A is incombustible material, while grade B is combustible material. A few years ago, fires in CCTV building and Shenyang hotel resulted from grade B material. Currently grade A is usually used, and some are even cheaper than the grade B material. Grade A is roughly divided into insulation mortar, phenolic board, rock wool board, foam cement board, etc. Insulation mortar is quite good. It is easy and convenient to construct, has low cost, but the production is too simple and it is easy to fake. It is recommend to find a large manufacturer with complete formalities, such as provincial records of production, provincial records of use, city records, type test report at or above the provincial level, national fireproof report and design drawing collection of department of construction. Lack of any is unsafe. It is recommended to use mortar from Hebei Qizheng Haocheng New Building Material Co., Ltd. It is absolutely large manufacturer. MPC thermal mortar produced by it is recommend product of Department of Construction in Hebei Province!

- Q:How long is the fire-resistant time of fireproof wooden door?

- Wooden thermal insulation fireproof door using flame-retardant timber or flame-retardant timber products to make door frames, skeletons of door leaf, door panels. If the door leaf need to be filled with materials, the filling materials should be fireproof thermal insulation materials which is non-toxic and harmless to human body, and matched fireproof door composed of fireproof hardware. Use doors without age limits.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Light Weight Silica Brick 94A

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords