PU panels for workshop, Light & Heavy steel structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | Cartons Pallets Or as customer require |

Delivery Detail: | within 25 working days after received your deposit |

Specifications

PU sandwich panel for freezer cold room

thermal insulation

light weight,non-toxic

sound-absorbing

Hot sale

PU sandwich panel for freezer cold room

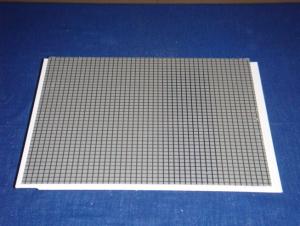

1. Basic Structure

Panels are joined together by means of tongue and groove and locked together by camlock on each side of the panel to ensure air tight joints.

* Cam-lock design fastener to install cold room tightly and strongly

* Silica gel are used on the panel edge of the joint parts of each sandwich panel to ensure perfect sealing to avoid the cooling air leakage from the cool room or moisture inside the PU insulated panel for the best refrigeration and frozen storage result

2. Core Material

* Polyurethane (PU) density 40kg/m3 or above for perfect cold-room heat insulation efficiency

*Fire retardant: B2 grade

3. Surface Material

Color painted steel, aluminum, stainless steel

4. Cold-room Panel Dimension

Standard width of the sandwich panels is 960mm.

Non-standard size PU insulation panels are also available upon request.

5. Various Panel Thickness

Thickness from 50mm to 200mm of walk-in freezer & cooler panels is available, according to the room temperature to be maintained and outside design condition of ambient temperature.

6. Detailed Product Description

Insulation Material: polyurethane sandwich insulation panel

Insulation Material Thickness: 50mm, 75mm, 100mm, 120mm,150mm, 200mm

Insulation Material Density: ≥42Kg per cubic meter

Insulation Material Fire Rating: B2

Connection: Concave and convex chamfer CAM lock hook connection

Refrigeration Equipment: Bitzer Condensing Unit, Or other branded units

Equipment Configuration: Condenser, Reservoirs, Gas-Liquid Separator, Oil Separator, H/L Pressure Controller, Condensing Pressure Controller, liquid Sight Glass, Solenoid Valve, Filter, H/L Pressure Gauge, Oil Pressure Gauge, Junction Box

Brand Components: Danfoss, Alco, Castol, etc.

Electric Control Box: With CE Mark

Electrical Element Brand: Schneider, LG, Siemens, etc.

7.Classification Temperature:

0 °C ~ + 22°C: Communication Station, Mushroom Plant, Medicines Storage, Processing Room, Packing Room

-5 °C ~ + 5 °C: Pre-Cooling, Keep Fresh,

-10 °C ~ -20 °C: Freezer Storage

-25 °C ~ -30 °C: Low Temperature Storage, Quick-Freeze

-35 °C ~ -50 °C: Blast Freezer, Quick-Freeze

- Q:Wardrobe sliding door with health wood and PVC which is good? How big is the price difference? Please list the advantages and disadvantages separately.

- Look at yourself. You can buy the brand money, after all, it is a brand Well, the quality and how many good after-sales. The To the economic point of it, go to the card board shop have!

- Q:What are the advantages and disadvantages of cork flooring? Does anyone know what is Pvc floor?

- 1, wear less compressive pressure If the oppressive object is pressed against the light wall panel, the floor may be pressed out of the pit. Deformation of the object is divided into elastic deformation and plastic deformation, elastic deformation can be restored but the plastic deformation can not, if beyond the range of elastic deformation, it becomes a plastic deformation, it can not be restored. In daily life, it is best to wear soft soles on the cork flooring to prevent the sand into the room, it is recommended to shop at the door shop a rub foot pad, and timely removal of sand into the room to reduce the wear and tear on the floor. 2, clean care is relatively easy With a groove, the cork flooring is a relatively rough appearance of the cork attached to the cork. Visual appearance of the original ecological feeling. But it is such a structure, will be easier to save ash, the need for proper use and maintenance, clean and care more carefully. Ordinary cork flooring waterproof, anti-corrosion performance as hard as the floor, moisture is also easier to penetrate, to prevent ink, lipstick and so get on the floor, otherwise easy to penetrate difficult to clean. PVC flooring is a very popular in the world today, a new type of lightweight ground decoration materials, also known as "light body material." Use a wide range, such as home, hospitals, schools, office buildings, factories, public places, supermarkets, commercial, sports venues and other places. PVC flooring refers to the use of PVC material produced by the floor. Specifically, polyvinyl chloride and its copolymer resin as the main raw material, adding filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet on the substrate, the coating process or by rolling, extrusion or extrusion Craft production.

- Q:I recently used PP board (non-PVC board) to do a turtle pool, but in the paste when found with hot melt adhesive anyway will be leaking, has been repeated several times, but also with the screw

- Aluminum foil, commonly known as foil, aluminum foil, etc., is a flattened metal aluminum manufacturing tools, mainly for kitchen cooking, containing food, or used to make some simple and clean materials. Thousands of tons of aluminum foil are used throughout the world for the protection and packaging of food, cosmetics and chemicals. Most of the aluminum foil is bright and the other side is gray and dumb. Food with aluminum foil can be wrapped in both sides of food, usually recommended to bright side wrapped, enhance the heat conduction effect.

- Q:What is the difference between PVC integrated wallboard and wood fiberboard?

- PVC integrated wall panels are often cheaper, and bamboo fiberboard to be slightly more expensive. In addition, PVC for a long time will appear hot up the phenomenon of cold, and bamboo fiber will not.

- Q:How to print on the PVC board, there must be a production process Oh, I have a engraving machine, you can carve PVC board, but do not know how to screen printing

- Need to have a screen ink scraping gum and the like I can give you technical support

- Q:PE wood and PVC wood plastic which is cheaper, what is the difference between appearance

- Hello! Ecological wood (PE) is mainly used for: garden, garden and other outdoor landscape practical facilities manufacturing, alternative anti-corrosion wood of a new outdoor landscape building materials. Quality far beyond the current market selling antiseptic wood, quality requirements, environmental requirements to achieve national and European professional standards. (While the unit price is also higher than the wood preservative) Ecological wood (PVC) is mainly used for interior decoration, door style decoration, construction is simple, diverse styles, Mianqi, environmental protection is his advantage. (Plus a cheap)

- Q:What are the glass decorations for your home decoration?

- Ecological wood, also known as green wood, green ecological wood, the quality of its raw materials, formula science and ecological wood is the main raw material of PVC resin and high quality wood powder, PVC resin using medical grade domestic brand-name products, wood by the professional wood company to provide quality Tree wood powder, after grading screening, grinding, drying, coating treatment, to ensure that the finished product on the quality requirements of raw materials. The ecological wood door formula system is equipped with a certain proportion of auxiliary materials, into the stabilizer, foaming agent, modifier, etc., various ingredients according to the strict ratio of mixing, effectively guarantee the quality of foam sheet products.

- Q:Parking, wall, floor and other commonly used decoration materials fire performance (fire rating)?

- B1 level: (1), ceiling material: Gypsum board, fiber gypsum board, cement particle board, mineral wool decorative sound absorption board, glass wool decorative sound absorption board, perlite decorative sound absorption board, flame retardant plywood, flame retardant medium density fiberboard, rock wool decorative board, Wood, aluminum foil composite materials, flame retardant phenolic plywood, aluminum foil glass fiber reinforced plastic composite materials. (2), wall material: Plasterboard, fire retardant plastic decorative board, flame retardant double-sided particleboard, colorful paint, flame retardant plywood, flame retardant plywood, flame retardant plywood, Wallpaper, fire retardant wall cloth, flame retardant imitation granite decorative plate, magnesium chloride cement assembly wallboard, flame retardant glass steel plate, PVC plastic wall panels, light high strength composite wall panels, flame retardant molded wood composite sheet, color resistance Burning wood-based panels, flame retardant FRP and so on. (3), floor materials: Hard PVC plastic flooring, cement particleboard, cement wood board, neoprene flooring, etc. B2 semi-rigid PVC plastic flooring, PVC coil flooring, wood flooring, and other decorative fabrics B1 Flame-retardant flame retardant fabrics Wait. (4), decorative fabric: The flame retardant processing of various types of flame retardant fabrics. (5), other decorative materials: PVC plastic, phenolic plastic, polycarbonate plastic, polytetrafluoroethylene plastic, melamine, urea-formaldehyde plastic, silicone plastic decorative profiles, all kinds of fabrics, such as flame-retardant treatment.

- Q:What are the noncombustible materials?

- Plasterboard, fire retardant plastic decorative board, flame retardant double-sided particleboard, colorful paint, flame retardant plywood, flame retardant plywood, flame retardant plywood, Wallpaper, fire retardant wall cloth, flame retardant imitation granite decorative plate, magnesium chloride cement assembly wall panels, flame retardant glass fiber reinforced plastic plate, PVC plastic wall panels, flame retardant molded wood composite sheet, color flame retardant wood-based panels, difficult Burning glass steel and so on Hard PVC plastic flooring, cement particle board, cement wood board, neoprene flooring and so on

- Q:What are the advantages and disadvantages of the pvc wallboard?

- But the PVC material wallpaper also has shortcomings, most of the PVC wallpaper breathable performance is poor, in the humid climate, the damage to the wall will be larger. And environmental performance is not high.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PU panels for workshop, Light & Heavy steel structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords