PTP foil, cold-forming foil, aalu-alu alu foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification

pharmaceutical foil

Application: PTP foil, cold-forming foil, aalu-alu foil

Alloy: 8006/ 8011/ 8079

Temper: H18/O

Thickness& Tolerance: 0.02mm-0.09mm(±6%)

Width& Tolerance: 200mm-1650mm(±1mm)

Mechanical Properties: Tensile Strength(U.T.S)≥160Mpa, Elongation≥1%

Standard: GB/T31988/ASTM-B209/EN546

2. Description

Chemical

Corrosion resistance can be excellent due to a thin surface layer of aluminium oxide that forms when the metal is exposed to air, effectively preventing further oxidation.The strongest aluminium alloys are less corrosion resistant due to galvanic reactions with alloyed copper.This corrosion resistance is also often greatly reduced by aqueous salts, particularly in the presence of dissimilar metals.

In highly acidic solutions aluminium reacts with water to form hydrogen, and in highly alkaline ones to form aluminates— protective passivation under these conditions is negligible. Also, chlorides such as common sodium chloride are well-known sources of corrosion of aluminium and are among the chief reasons that household plumbing is never made from this metal.

However, owing to its resistance to corrosion generally, aluminium is one of the few metals that retain silvery reflectance in finely powdered form, making it an important component of silver-colored paints. Aluminium mirror finish has the highest reflectance of any metal in the 200–400 nm (UV) and the 3,000–10,000 nm (far IR) regions; in the 400–700 nm visible range it is slightly outperformed by tin and silver and in the 700–3000 (near IR) by silver, gold, and copper.

Aluminium is oxidized by water at temperatures below 280°C to produce hydrogen, aluminium hydroxide and heat:2 Al + 6 H2O → 2 Al(OH)3 + 3 H2

This conversion is of interest for the production of hydrogen. Challenges include circumventing the formed oxide layer, which inhibits the reaction and the expenses associated with the storage of energy by regeneration of the Al metal.

3. Our advantage

Best price!

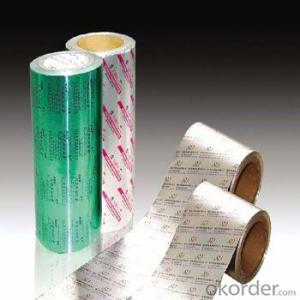

4.Pictures

5.FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:HOWEVER THE PERSON SAID THIS IS THE FIRST SPYDER ELECTRA MODEL THAT CAME OUT

- Is it for a stove? True Value sells it.

- Q:I opened one of those huge cans of ketchup - filled up a few squeeze bottles - covered the can with foil - and stuck it in the fridgeMy boss tripped out and said that an open aluminum can will poison the contents when refrigeratedI kind of don't believe that because years ago when I had a cat, I bought the canned food and little plastic lids that were specifically for those cans to store them in the fridge because the can was more than one serving for the catso whats the truth? if it is true, is it only with open cans?

- Wher I stay it may be complicated to declare, Wal-Mart is the only shop, and not making use of a 28 mile tensionproperly we've approximately 3 of those little kinfolk owned places that i won't manage to have the money for to shop in.

- Q:any suggestions?

- I'd go with blown-in cellulose or poured closed cell foamEither one could be a DIY project if you're handyEither could be a nightmare if you aren't Blown-in cellulose is least expensiveI added cellulose to my attic, and used tigerfoam in some exterior wallsBoth require a helperThe cellulose must be broken out of the packages and poured into the blower's hopper, and the foam requires a helper to move tanks and keep you from tangling the hosesThe key is the read everything you can find on both methods and decide how much time and help you 'll have on hand.

- Q:Got a problem with the following:Aluminium foilt Thickness 1.5mmEf Fermi energy 11.6 eVT 300KP density 2.70 kg/m^3M Molar mass 27 g/moleW Work function 4.1 eVCalculate the chance of finding valance electrons outside the foil using Fermi - Dirac.The only fermi-dirac formula I can use is F(E) 1 / (e^((E-Ef)/kT)+1)What do I have to use for E?Thanks a lot!

- Sleep in a cold room Sleeping in a cold room is a best way to force your body to heat itself up for hours

- Q:I have no clue how to put these lab questions into sentences i've done all the work but i'm stuck on these questions1) How can the thickness of a piece of aluminum foil be determined, without actually measuring it?2) What does indirect observation have to do with the topic of atomic structure ?

- If you had Al foil and could cut it into a regular shape like a circle or a rectangle, you could measure the surface area with a rulerThen you could measure its mass on a balance and use the known density to calculate the volumeIf you had a rectangle, you would set that volume equal to the area times the thicknessYou now have the thickness without having directly measured it In atomic structure, many values (like atomic radius) have to be measured indirectly.

- Q:I made this peanut brittle about 4 hours ago and it is still really sticky, it never hardenedAnd it never got that golden brown colorI do not have a candy thermometer but I cooked it really hot and for about 10 min.Can I cook it more since I have it finished already ????Here is my recipe I followed and I did exactly what it said.1 csugar1 cwhite Karo syrup2 craw shelled peanuts1 tspsodaCook sugar, syrup and peanuts together until turns light amber color, stirring as neededRemove from heat and add 1 teaspoon soda and stirThe soda causes a foaming actionTurn out onto a piece of aluminum foilDo not try to smooth candy outLet cool and break into piecesLet pan cool before washing

- Wilton Cookie Sheets

- Q:I am making my own subwooferI have detailed plans along with the resources, and I know what I am doingPlease don't tell me it's a waste of my time or too complicatedAnyways I need a little help making the voice coilI have 3 N42 Neo Magnets 1-1/2quot; x 1/2quot; which the voice coil will surroundFirst off, do I need to wrap the coil around alluminum or will cardboard work (like a TP roll?)Next, I don't see how the voice coil will have 2 terminalsTo start the coil you have to glue down 1 end, and after wrapping up layers, that end would be covered right? So where does the 2nd end come from? Any help is appriciatedThank you

- Most commercial speakers use multiple strands of very fine wire to carry the current to the voice coil to allow it to move to produce that big bassSubwoofers have ligher displacements compared to other speakersThen use a heavier solid wire for the coil itselfLeave a spot to connect this wire to the start of the coil and use a similar flexible wire at the end of the coilYou do not want to leave an aluminum tube in the coil because eddy currents will be induced in the aluminumThink of it as a big shorted turn that will suck up your audio powerYou could cut a slot in it along one side (parallel to the axis) to break the shorted turn.

- Q:Does the foil foil of the cigarette case conduct electricity?

- The experts divided it into more than 20 varieties according to its application characteristics. Because of the difference of economic development in different countries, there is a big gap in the consumption structure of aluminum foil. In Europe and the United States, aluminum foil used in packaging accounts for 70% of the total demand. In the Chinese market, aluminum foil is mainly used as raw and auxiliary materials for industrial manufacture.

- Q:i have made a few, but they dont worki have all the holes i need, and by the way, i smoke jimson weedplease dont leave stupid answers like dont get stoned kid! or some shiiiit like that.

- I think I'm the only human here when I say, learn to balance your diet and understand what your eating and how your eating and when your eating itDrink water and try some digestive medicine (natural of course)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PTP foil, cold-forming foil, aalu-alu alu foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords