Pre-stressed Concrete Slabs Making Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-stressed Concrete Slabs Making Machinery

1. Structure of Pre-stressed Concrete Slabs Making Machinery:

Pre-stressed Concrete Slabs Making Machinery works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

2. Main Features of Pre-stressed Concrete Slabs Making Machinery:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

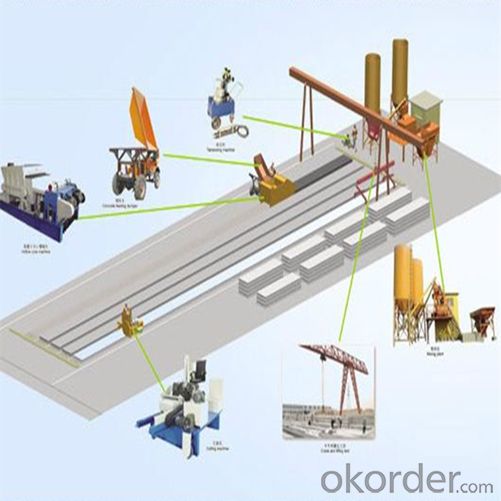

3. Pre-stressed Concrete Slabs Making Machinery Images:

4. Pre-stressed Concrete Slabs Making Machinery Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Layout

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q:i'm a Taiwan heavy industry and science instrument field agent. i hope i can use this website to contact factory owner to agent ther'e product.

- Best of Luck.

- Q:i need help w/ a science question lol....:] help please! thnx! o and also, the 1st question is more important, but if u know this one, it would help too: How is friction a factor in outer space?

- OK, I'm thinking about the situations you mention........now, what exactly was the question.......?! Nothing, including friction, is a (factor...?) in 'outer space'. Reason: there's nothing there.

- Q:Libraries in Chicago withcollections of trade catalogs. Chicago Machinery Exchange 1900-30?

- The Newberry Library (it's in the Gold coast) has many old items. They are very knowledgeable about this type of thing, they might know where to find it if they don't have it.

- Q:Is there any common pattern between the two?While several ultra-Islamist countries have draconian laws to punish everyone who slanders god, CCP is known to punish everyone who slanders the Chinese Communist Party. CCP often resorts to informal detentions, punishments and disappearances which are completely outside the law, and so offer the government deniability and the victim no protection whatsoever.Do the Chinese people find any commonality between the Blasphemy Laws practiced in Islamist countries and the draconian policies of CCP?

- Have you also noticed that these religious fanatics use God to justify their actions rather than the laws that benefit the people? It is similar in that China uses the welfare of the state rather than a god to get to the same end, and that is domination of the masses.

- Q:I'm in a tropical country, and heck, my whole life living here. I haven't experienced this kind of heat!I'm just a student, and because of that, I have no money to buy an ice cream maker.How can I make ice cream without a ice cream maker?

- Get 2 zip lock baggys. 1 gallon and 1 sandwich bag. U put ice cubes in the 1 gallon bag and then your choice of home made ice cream ingredients in the sandwich bag. Put the sandwich bag inside the 1 gallon bag... then... shake it for 10-15 minutes and bowww ice cream

- Q:I am going to be an interveiwer interveiwing either a Boatswain Mate or a Machinery Technician. I need links to websites with information about these types of people and their jobs because I need some information. Thank you.

- Boatswain okorder

- Q:machinery purchsed entry and derpeciation charged for it?

- The purchase: Dr. Machinery (Fixed Assets) Cr. Cash / Accounts Payable Depreciation: Dr. Machinery Depreciation Expense Cr. Machinery Accumulated Depreciation Note that the accumulated depreciation is a contra account for the fixed assets, and what appears on the Balance sheet is the net of the two figures.

- Q:what does machinery safety engineer do?

- Basically, they inspect every machinery and make sure that it is perfectly functional and that all safety standards are met. Safety engineers are also involved in the planning and consultation in the event that a machine is required to be moved or relocated. Safety engineers plays a major role in a machinery relocation firm such as the www.hanlonandwright .uk/.

- Q:Remember before the 1980s?When we had shop classes in our schools?When we actually made products in America?When we supplied the world with steel, machine tools, and automobiles?Remember when we had a working middle class?

- Yes . A farm tractor at the age of 8 . Had to run it standing up because if you sat down you couldn't reach the pedals .

- Q:would these include non motorized equipment used for processing?

- Baler------ This is pulled by the tractor and used to make bales out of crops like hay. It makes a round bale that is 4'x4' tall. Each bale will feed about 25 cows a day. Combine------ This is used to harvest all kinds of crops. It does more than one thing--like pick and clean the crop. It has a sieve in it to get rid of the crop junk. They even have special ones if the farmer has lots of hills. Chisel Plow----- Plows dig up the soil to get it ready for planting. It will turn over the dirt as it digs. Cotton Picker----This machine picks cotton and puts it into the back. The cab has air conditioning and a cassette player/ radio/ and weather radio. It has a special seat for back support. Mower---- This is pulled by a tractor and mows down grass and low growing things. Row Planter---The containers at the top hold the seeds to be planted. This is pulled across the field that the farmer wants to plant. Row Planter---The containers at the top hold the seeds to be planted. This is pulled across the field that the farmer wants to plant. Seed Drill--- This is pulled by a tractor. It is used to plant grains and vegetable seeds. This can make different kinds of ditches that the seeds go in depending on what kind of soil there is. Sprayer--- This is used if the farmer needs to spray their crops for anything [like bugs]. It has a great cab, or place where the driver sits. The equipment company builds these to make farmers more comfortable while they work. Tractor--- This is one of the most important pieces of equipment that a farmer has. He uses it to pull equipment and crop wagons. The equipment company makes the cabs of these very comfortable, too. The farmer picks the tractor size based on what he wants to pull with it. ()

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-stressed Concrete Slabs Making Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords