PPR Elbow 45 Degree Internal / External Pipe Fitting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: PP-R

Technics: Forged

Type: Elbow

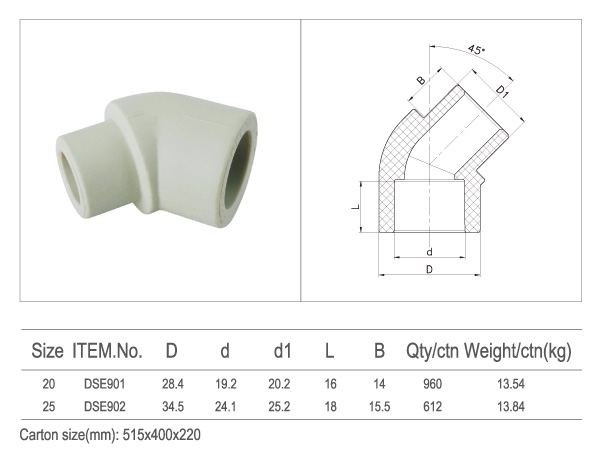

- Model Number: DSE901-902

- Connection: Welding

Shape: Equal

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20~25

Color: Green, White, Grey, Blue

Packaging & Delivery

Packaging Details: PE bag + carton

Delivery Detail: 15 Days

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

- Q:Are plastic pipe fittings resistant to water hammer?

- Yes, plastic pipe fittings are generally resistant to water hammer.

- Q:How do plastic pipe fittings handle abrasive fluids?

- Plastic pipe fittings are generally not recommended for use with abrasive fluids. The abrasive particles present in the fluid can cause wear and erosion on the plastic material, leading to potential leaks or failures in the fittings over time. It is advisable to opt for more durable materials such as metal or ceramic when handling abrasive fluids to ensure long-lasting and reliable performance.

- Q:Can plastic pipe fittings be used for pressure washing systems?

- Yes, plastic pipe fittings can be used for pressure washing systems. However, it is important to ensure that the fittings are made from durable and high-pressure resistant materials, such as PVC or CPVC, to withstand the water pressure generated by the pressure washer. Additionally, it is recommended to closely follow the manufacturer's guidelines and choose fittings that are specifically designed for pressure washing applications to ensure safe and efficient operation.

- Q:What kinds of plastic pipe fittings are there? What are the various uses? And how to distinguish quality?

- Meet our general tap, usually with silk accessories, is 1/2. Drainage fittings have straight through, elbow, three straight, different diameter three pass, different diameter sleeve, big small head, water storage bend, expansion joint, ventilation, flat four pass, three-dimensional four pass, oblique three pass, rain bucket, etc..

- Q:Are plastic pipe fittings resistant to impact and vibrations?

- Yes, plastic pipe fittings are generally resistant to impact and vibrations. They are designed to withstand the forces and movements associated with normal plumbing systems, making them a reliable choice for various applications. However, it's important to choose fittings that are specifically designed for impact and vibration resistance if they will be exposed to more intense or frequent forces.

- Q:What are the specifications of PVC tubes?

- Deng Quan plastic PVC-U drainage pipe is a well - developed drainage pipe series, which has been widely used at home and abroad. Deng Quan plastic production of PVC-U water supply pipe has long service life compared to the cast iron pipe, corrosion resistance and other advantages; in the construction of more light weight characteristics, handling installation and easy connection are widely used in the civil construction of sewage, chemical sewage, rainwater and other fields. PVC-U drain pipe, pipe fittings comply with the standard requirements of GB/T, 5836.1-2006 and GB/T 5836.2-2006. Pipe specification (mm)

- Q:How to set the quota for plastic pipe fittings?

- If the valve without quota, quota to perform a similar process can be performed in the similar process quota of plastic pipe section is appropriate, according to the material included in the flange.

- Q:Are plastic pipe fittings suitable for underground cable protection?

- No, plastic pipe fittings are not suitable for underground cable protection as they may not provide adequate strength and durability required for protecting cables from external factors and potential damage. Metal conduit fittings are commonly used for this purpose due to their superior strength and ability to withstand environmental conditions.

- Q:Can plastic pipe fittings be used in culvert systems?

- Yes, plastic pipe fittings can be used in culvert systems. Plastic pipe fittings are commonly used in culvert systems due to their durability, corrosion resistance, and ease of installation. They are lightweight, cost-effective, and can withstand the pressures and environmental conditions typically found in culvert systems. Additionally, plastic pipe fittings offer a variety of options to accommodate different pipe sizes and configurations, making them suitable for various culvert applications.

- Q:Are plastic pipe fittings compatible with copper pipes?

- Yes, plastic pipe fittings are compatible with copper pipes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR Elbow 45 Degree Internal / External Pipe Fitting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords