PP/PE waterproof materials for bathroom and toilet floor waterproofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP& PE compound membrane waterproof material for walls is made by multiple-ply different materials, especially its aging and weathering resistance layer enables the

membrane possess more longer effective age. It can bond with many kinds of adhesions,

firm and secure. In case of cement-base, cementations agent can be used,

the cementations agent can easily enter into the non-woven felt layer, forms a

well-combination with cement after solidification, permanent durability.

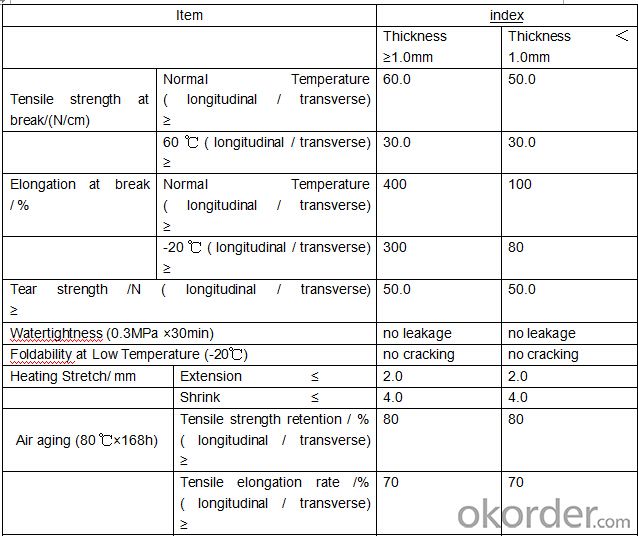

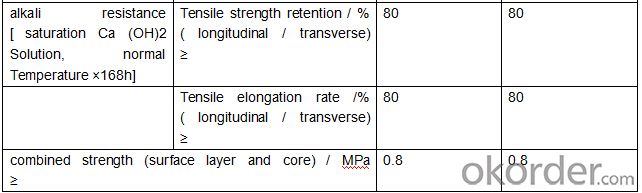

Data Sheet

Characteristic:

1. Non-toxic, no pollution, environmental protecting product.

2. Can be used for many different surfaces, especially for cement basement.

3. Tough, impermeable, multi-layered sheet;

4. High tension strength, good cold flexibility.

Application:

Products used in roofing, basement, restroom, water conservation, warehouse to protect structure from water infiltration.

- Q:Can waterproofing membranes be installed on uneven surfaces?

- Yes, waterproofing membranes can be installed on uneven surfaces. In fact, one of the advantages of waterproofing membranes is their ability to conform to various irregularities and unevenness in the surface. These membranes are typically flexible and can be easily molded and adjusted to fit the contours of the substrate. Additionally, some waterproofing membranes have self-adhesive properties or can be applied with adhesives, allowing them to adhere to both smooth and uneven surfaces effectively. However, it is important to note that proper surface preparation is crucial for a successful installation. The surface should be clean, dry, and free from any loose materials or debris to ensure optimum adhesion and performance of the waterproofing membrane.

- Q:Can a waterproofing membrane be used on stucco surfaces?

- Yes, a waterproofing membrane can be used on stucco surfaces. Waterproofing membranes are often applied to stucco surfaces to protect them from water damage and enhance their durability. These membranes create a barrier that prevents water from seeping into the stucco, helping to maintain its integrity and preventing moisture-related issues such as cracking or mold growth.

- Q:How long does it take for a waterproofing membrane to dry?

- The drying time of a waterproofing membrane can differ based on various factors, including the kind of membrane used, prevailing weather conditions, and the method of application. Typically, it will take a minimum of 24 to 48 hours for most waterproofing membranes to completely dry. It is crucial to refer to the instructions provided by the manufacturer for precise drying times, as they might vary. Furthermore, factors such as temperature, humidity, and ventilation can impact the drying process. It is advisable to guarantee adequate ventilation and allocate enough time for the membrane to dry before exposing it to any moisture or foot traffic.

- Q:Can waterproofing membranes be used on expansion joints?

- Yes, waterproofing membranes can be used on expansion joints. Expansion joints are designed to accommodate movement and prevent damage caused by thermal expansion or contraction of building materials. Waterproofing membranes can be applied to expansion joints to create a barrier against water infiltration, which helps to maintain the structural integrity of the joint and prevent water damage to surrounding areas. It is important to select a waterproofing membrane that is flexible and able to withstand the movement of the joint without cracking or deteriorating. Additionally, proper installation techniques should be followed to ensure a watertight seal around the expansion joint.

- Q:Does a waterproofing membrane require any specific safety precautions during installation?

- Yes, installing a waterproofing membrane does require specific safety precautions. These may include wearing protective clothing, such as gloves and goggles, to prevent contact with chemicals or materials that may be harmful. It is important to ensure proper ventilation in the installation area to minimize exposure to potentially harmful fumes or vapors. Additionally, following manufacturer's instructions, using proper tools and equipment, and working in a well-organized manner can help prevent accidents or injuries during the installation process.

- Q:Are waterproofing membranes resistant to gasoline?

- Yes, waterproofing membranes are generally resistant to gasoline. Most waterproofing membranes are designed to be chemically resistant and can withstand exposure to various chemicals, including gasoline. However, it is important to note that the level of resistance can vary depending on the specific type of membrane and its composition. Some membranes may offer better resistance to gasoline than others. Additionally, prolonged exposure to gasoline can still potentially damage or degrade the membrane over time, so it is always recommended to take necessary precautions and avoid prolonged exposure to harsh chemicals.

- Q:Can a waterproofing membrane be used on tunnels with subway systems?

- Yes, a waterproofing membrane can be used on tunnels with subway systems. In fact, it is highly recommended to install a waterproofing membrane in subway tunnels to prevent water infiltration and potential damage to the structure and electrical systems. The waterproofing membrane acts as a barrier to keep water out and protect the tunnel from moisture-related issues such as corrosion, mold, and deterioration. It is important to choose a waterproofing membrane that is specifically designed for tunnel applications and can withstand the unique conditions and challenges of subway systems, such as high traffic loads, vibrations, and exposure to chemicals. Additionally, the installation of the waterproofing membrane should be done by experienced professionals following the appropriate guidelines and specifications to ensure its effectiveness and longevity.

- Q:Are waterproofing membranes resistant to wind-driven rain?

- Waterproofing membranes, in general, exhibit resistance to rain propelled by wind. Their purpose is to establish a safeguard against the intrusion of moisture, specifically rainwater. These membranes are commonly constructed from rubber, asphalt, or synthetic polymers, all of which possess a formidable ability to repel water. Moreover, numerous waterproofing membranes are fortified with additives or multiple layers to augment their robustness and longevity, enabling them to endure the forceful impact of wind-driven rain. Nevertheless, it is crucial to acknowledge that the efficacy of waterproofing membranes may be contingent upon the meticulousness of the installation techniques employed and the quality of the materials utilized.

- Q:Can a waterproofing membrane be used for a basement floor?

- Yes, a waterproofing membrane can be used for a basement floor.

- Q:Does a waterproofing membrane require any special precautions during installation?

- Yes, a waterproofing membrane does require special precautions during installation. It is important to ensure that the surface to be waterproofed is clean, dry, and free from any contaminants or loose materials. The membrane should be installed in accordance with the manufacturer's instructions, paying attention to proper overlap and seam sealing. It is also crucial to inspect the membrane for any damage or defects prior to installation. Additionally, proper safety measures should be taken, such as wearing protective clothing and using appropriate tools and equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP/PE waterproof materials for bathroom and toilet floor waterproofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords