PP Caps Color Coated Aluminium Coils New Year Promotion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

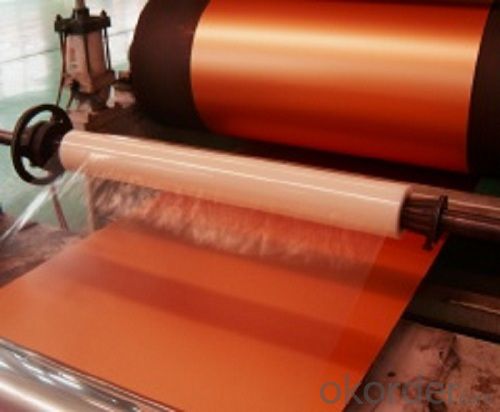

PP Caps Color Coated Aluminium Coils New Year Promotion

l Product Information

1. Type:Aluminum Coil

2. Alloy: 8011

3. Temper: H24/14

4. Thickness: 0.21mm

5. Width: 100-2500mm or as your request

6. Length: produce as your request

7. Weight: produce as your request

8. Color: One side with colored lacquer and the other side with transparent lacquer or both sides with transparent lacquer.

9. Application: The coated aluminum coil with variety colors widely used on the production of caps, such as wine bottle cap, medicinal liquid lids and cosmetic caps.

10. Surfure: Smooth, clean, be free of scratch and corrosion

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q:What is the modulus of elasticity of aluminum coils?

- Young's modulus, which is also referred to as the modulus of elasticity, quantifies the stiffness and resistance to deformation of aluminum coils when subjected to an external force. Typically, the modulus of elasticity for aluminum coils falls around 70 GPa (gigapascals) or 10 million psi (pounds per square inch). However, this value can slightly fluctuate depending on the particular alloy and temper of the aluminum utilized in the coils. Consequently, the modulus of elasticity plays a crucial role in determining the durability and malleability of aluminum coils, making it a significant consideration in various sectors such as construction, automotive, and aerospace industries.

- Q:How are aluminum coils used in the production of battery enclosures?

- Aluminum coils are used in the production of battery enclosures as they provide a lightweight and durable material that can be easily molded and shaped to form the enclosure. The coils are typically processed and formed into specific shapes using a combination of heating, rolling, and cutting techniques. This allows for the creation of seamless and tightly sealed enclosures that can protect the batteries from external elements and provide efficient heat dissipation.

- Q:How to calculate the weight of strips with the weight of aluminum coil known?

- Thickness*width*length=weight/density, length=weight/(density*thickness*width).Ps: Keep unit the same.

- Q:and alsoHow many grams of the decay product will have formed after 8 days go by?The decay product is the new isotope created as a result of the positron decay of aluminum-24.In class my teacher didn't explain this completely but there's a question on the homework that me and even my mom (another teacher) can't find the answer to.

- so it 6000/ (2*8*24*60*60) 0.00434027778 grams have you heard of the internet an unless your mom is a chem teacher it doesnt mean much

- Q:How are aluminum coils tested for dimensional accuracy?

- Various methods are used to test the dimensional accuracy of aluminum coils to ensure they meet the required specifications. One method commonly employed is the use of specialized equipment like calipers, micrometers, and digital measuring devices. These tools enable precise measurement of the coils' width, thickness, and length. During the testing process, a sample coil is chosen and measured at different points along its length to detect any variations or deviations from the specified dimensions. This helps identify any potential issues with the coil's dimensional accuracy. In addition to manual measurements, advanced technologies such as laser scanning systems and optical sensors are also utilized. These technologies allow for non-contact measurements, resulting in faster and more accurate assessments of the coil's dimensions. Laser scanners create a digital representation of the coil's surface, which can then be compared to the desired specifications to determine the presence of any deviations. Furthermore, computerized systems are employed to analyze the collected data and generate detailed reports. These reports provide comprehensive information about the coil's dimensional accuracy, highlighting any discrepancies from the required standards. This data analysis enables manufacturers to promptly identify and address any potential problems. In conclusion, stringent testing procedures are applied to aluminum coils to ensure their dimensional accuracy. The combination of manual measurements, advanced technologies, and computerized analysis provides a thorough assessment of the coils' dimensions. This enables manufacturers to maintain high-quality standards and deliver products that meet the precise specifications demanded by various industries.

- Q:I would like to order 25 micron diameter 99.99% Aluminum wire required to use for making electrical connections. Only several cm are needed, so I would like to purchase a small spool. Delivery ASAP preferable (overnight or two day shipping would be best). This wire will be attached by hand using epoxy and not using a wire bonder.

- If they can't help, try asking the tech support guys at the wirebond manufacturers and the tool manufacturers. KS in the US and Shinkawa in Japan used to be the big guys. You can search for ultrasonic bond tools. You can also check with superconducting research centers; several private and public ones. Researchers might loan you materials and/or bonding support. BTW, Al critical temp is reportedly about 1.2°K, pretty tough to get that cold! U/S bond wire has 1% silicon, partly for hardness, you can probably bond pure wire though. Key is breaking up the oxide. Maybe bonding at cold temps and/or in vacuum would work. Also, I doubt epoxy would be good or superconducting at the temps. Al filled epoxy is unreliable electrical conductor due to oxide formation. Will be a bear to handle such fine wires without a bonder! Good luck!

- Q:Can aluminum coils be used in the production of beverage cans?

- Certainly, beverage cans can indeed be produced using aluminum coils. Aluminum is the preferred material for manufacturing beverage cans due to its lightweight nature, durability, and ability to maintain the taste and quality of the contents. Typically, aluminum coils are employed in the canning process as they can be readily molded into the desired can shape. These coils are rolled into sheets, which are subsequently cut and transformed into cans. Additionally, aluminum coils possess exceptional heat conductivity, enabling efficient cooling and faster production rates. All in all, aluminum coils play a crucial role in the production of beverage cans and are extensively utilized within the industry.

- Q:How are aluminum coils used in the production of automotive parts?

- Aluminum coils play a crucial role in the production of automotive parts. Due to their lightweight and corrosion-resistant properties, aluminum coils are extensively used in the manufacturing of various automotive components. One of the main applications of aluminum coils in the automotive industry is in the production of body panels. These coils are processed into sheets, which are then formed and shaped into body panels such as hoods, doors, fenders, and roofs. The lightweight nature of aluminum helps to reduce the overall weight of the vehicle, resulting in improved fuel efficiency and better handling. Aluminum coils are also used in the production of heat exchangers for automotive air conditioning systems and radiators. The excellent thermal conductivity of aluminum allows for efficient heat transfer, ensuring optimal cooling performance. This helps to maintain the desired temperature in the vehicle's interior and prevent engine overheating. Additionally, aluminum coils are utilized in the production of various engine components. They are widely used in the manufacturing of cylinder heads, engine blocks, and intake manifolds. The high strength-to-weight ratio of aluminum makes it an ideal material for these applications, as it provides strength and durability while reducing the overall weight of the engine. Moreover, aluminum coils are used in the production of suspension components such as control arms and subframes. The lightweight nature of aluminum allows for better suspension performance, resulting in improved handling and a smoother ride. In summary, aluminum coils are extensively used in the production of automotive parts due to their lightweight, corrosion-resistant, and high-strength properties. They are employed in the manufacturing of body panels, heat exchangers, engine components, and suspension parts, contributing to the overall performance, efficiency, and durability of vehicles.

- Q:What are the different types of end conditions for aluminum coils?

- Aluminum coils have several types of end conditions, which determine how the ends of the coil are prepared for different applications. Some common end conditions for aluminum coils are as follows: 1. Mill Finish: This is the most basic and widely used end condition for aluminum coils. In mill finish, the coil ends are left untouched after coming off the rolling mill, without any additional processing or finishing. This end condition is suitable for applications where the appearance of the ends is not crucial. 2. Trimmed or Sheared: In this end condition, the coil ends are trimmed or sheared to eliminate any uneven or rough edges. This results in clean and smooth ends, which are often necessary for applications that require precise fitting or appearance. 3. Slit: Slitting refers to cutting an aluminum coil into narrower strips or coils. Slitting is commonly done to customize the width of the coil according to specific requirements. The ends of slit coils can have either mill finish or trimmed ends, depending on the desired application. 4. Recoiled: Recoiling involves rewinding a coil into a smaller or larger coil diameter. This end condition is frequently employed when smaller coils are needed for storage, transportation, or further processing. Recoiling can be done with or without additional trimming or shearing of the ends. 5. Flattened: Flattening is the process of unrolling and flattening the coil to create a sheet or plate. This end condition is often used when the aluminum is intended for further fabrication, such as stamping, forming, or cutting into specific shapes or sizes. The ends of flattened coils are typically trimmed to ensure a clean edge. It is important to note that the specific end condition required for aluminum coils may vary depending on the intended application and customer specifications. Different industries and uses may have unique end condition requirements to ensure optimal performance and appearance of the aluminum coils.

- Q:Are there any limitations to the maximum coil length of aluminum coils?

- Yes, there are limitations to the maximum coil length of aluminum coils. The length of aluminum coils is typically restricted by factors such as the capabilities of manufacturing equipment, transportation constraints, and handling limitations. Additionally, longer coils are more prone to issues like coil sagging and deformation during storage or handling. Therefore, there is a practical limit to the maximum coil length that can be produced and effectively utilized in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Caps Color Coated Aluminium Coils New Year Promotion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords