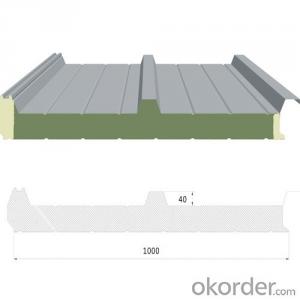

Popular Rockwool Sandwich Panel High Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

rockwool sandwich panel high strength

Our sandwich panels are a new kind of construction panels. As the common,It consists three layers:two Color Painted Steel sheets and the core. Meanwhile, we apply the PIR side sealing technology,Which could greatly improve the performance of insulation and waterproof.

Features:

1) Material of the core.

Rockwool fibres is made from pure natural rock minerals.such as basalt and gabbro. This kind of "man-made mineral fibres" contains very low dust and slag. Also, the acidity coefficient is higher than the come mineral wool that means a lower corrosion to the metal. This Rockwool has a good performance on the hydrophobe,So the insulation could be sustaining for a very long time.

2) water resistant, Heat insulation and heat preservation

By the PIR side sealing technology, the performance of water resistant, Heat insulation and heat preservation has been greatly raised.meanwhile it also retains very good firproof.

3. producing control

Turning 90 degrees after cutting, assure the fiber direction perpendicular to the sheet to increase the strength

Imported fire-proof adhesives sprayed on the sheets evenly to make sure the panel is firmly for a long time.

- Q:I have not been crocheting long and I have many sizes of hooks.most of them are aluminum hooks with bamboo handles from a brand called YarnologyI do have 2 larger hooks that I really have not yet used and one is a Boye and one a Susan Bates.I can see that the Yarnology hooks are similar to the Boye.What brand of hook do you prefer and why? Also, do you like metal, plastic, bamboo.? And how do you hold your hook? Thank you.

- I prefer plain straight metal hooksI don't like joins where the hook is made of 2 materials or fancy curly handles.

- Q:I really need a bowl bc I'm tired of being stuck without blunts plus bowls are so much easier to use if you could just tell me how I can get one maybe online or something? I'm from Minnesota if that helps.

- Aluminum 26( atomic mass) - 13 (atomic number) 13 neutrons protons are the atomic number which is 13 +14 ( added onto the aluminum) 27 therefore when you draw out the lewis dot it should have 3 on the outer shell + 14 17 electrons if the protons and neutrons are equal then the amount of electrons are the same as protons and neutronssorry if this isn't right!!

- Q:please, i need help!

- It's a small venue,bands love places like that,yeah it's in Flint but nothing ever happens to it,not alot of people and you know the real fans are going to show up,those are the best shows to go see and the bands know that.

- Q:I am cooking dinner for a date tonight, She says she wants Baked PotatoesI have never made them, Please help someone!!!

- replace the casenothing out there to do a quick fix.

- Q:is 2.70g/cm^3, what is the thickness of the foil in mm?

- Never put any metal in a microwave! It could start a fire, or burn out the tube.

- Q:soda cans, paper, cardboard etcpermanent fixtures or landfill?

- Heck yes! Sometimes ppl will stare and I just let them because I like the attention.

- Q:for example, if u open up a MY DOG tray 100g dog food it smells amazing, hell even i want to eat it! but when u get a canned variety of the same flavour, its somehow differentthe meat doesnt smell as nice, almost like it is more processedmy jack russell doesnt enjoy eating it as much, yet it still claims to be the same?why?also, why doesnt the tray tin ones come in the same canned form? does the aluminum in the can have something to do with it?

- I think the one in the tray likely needs more preservatives to keep it fresh / safe.

- Q:A clear plastic pen of length 14.5cm is rubbed with wool hence giving the pen negative charge, the the pen is brought near a neutral disk shaped aluminium foil of diameter 0.5cmI have to figure out how close I must bring the pen to the foil before the foil starts getting attracted.Plz Please please help me !!!!!!!!!!!!!11.I really thank you for your time.

- Well, I think you would need to know the amount of charge on the penBringing the pen close to the center of the foil disk would induce a positive charge at the center of the foil and a negative charge at the foil edgeThe electrostatic force to overcome gravity depends on the amount of the charge as well as the thickness of the foil which also isn't given.

- Q:I was wondering how much folds/layers will be needed to be equal to the thickness of a soda can's sides? (The sides, the part you hold on to)

- No-Bake Cookies 2 cups sugar ? cup cocoa powder ? cup milk 1 stick butter ? cup peanut butter 1 teaspoon vanilla 3 cups rolled oats Combine sugar, cocoa, and milk in pan and boil for 1 minStirring constantlyAdd remaining ingredients, and mix togetherDrop with teaspoon on foil paper(I use tin foil instead of wax paper - I have better luck with them setting up on tin foil) Tip: I have used this recipe for years, and I know can be tricky, be sure to add the exact ingredients, no extras, and be sure to boil the hot mixture for 1 complete minute Enjoy!

- Q:Which leaves the smallest carbon footprint returnable beer bottles or recyclable aluminium cans?

- recycling Aluminum cans requires less energy, therefore less fossil fuel for the process, but produces more pollution in the melting process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Popular Rockwool Sandwich Panel High Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords