Polypropylene Fiber for Reinforcement with 12mm 18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Fiber Introduction

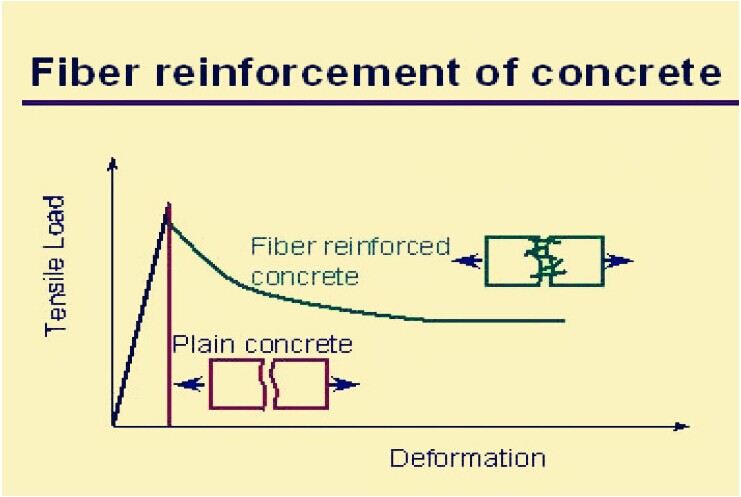

Polypropylene fiber also called PP fiber, is a new type of reinforcing and crack-resistant building material for bitumen concrete reinforcement. It is produced by special technique.With polypropylene as its raw material,fiber-mesh is produced by special technology.It appears net-like structure with many monofilaments connected.

The horizontal structure in monofilament can be destroyed in the course of the stirring owng to friction and rubbing,and the monofilament or net like structure will fully stretch, thus the concrete is reinforce by a great number(more than 7 million pieces per cubic meter) of polypropylene fibers.

Technical Data of Polypropylene Fiber for Reinforcement with 12mm 18mm

Raw Material | Polypropylene | Crack Elongation | 20%±5% |

Type | Monofilament | Density | 0.91±0.01g/cm3 |

Fiber Diameter | 0.02-0.05±0.005mm | Melting point | 160-170 |

Tensile strength | ≥450mpa | Resistance to acid, alkali | Strong |

Size | 6, 12, 10, 15, 19, 20, 24, 48mm | Water absorbency | no |

Product Function of Polypropylene Fiber for Reinforcement with 12mm 18mm

1) improve the crack resistance of mortar and concrete

2) improve the permeability resistance of mortar and concrete greatly

3) improve mortar, concrete resistance to impact, bending and seismic performance

4) improve wear resistance of mortar and concrete

5) improve the antifreeze performance of mortar and concrete

6) strong dispersion, workability

7) good chemical stability, acid and alkali resistant capability is strong, safe non-toxic, for reinforcement corrosion damage

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

Product effect Photo of Polypropylene Fiber for Reinforcement with 12mm 18mm

4. Product Application of Polypropylene Fiber for Reinforcement with 12mm 18mm

1), building engineering, mortar, concrete structure of civil and industrial buildings, including site casting, beam-column, the basement floor and side panel, roof cast-in-place floor slab, pool structure, crack resistance, impact resistance, high wear resistance requirements of engineering.

2), municipal engineering, concrete road and square, bridge, tunnel, subway, port terminals, interchange bridge, bridge, airport runway, super long structure, etc.

3), water conservancy project: levees, DAMS, etc.

4), antiknock, refractory engineering: civil air defense, military engineering, oil platform, chimneys, refractory materials, etc.

5), shotcrete, tunnel, culvert lining, thin-walled structure, slope reinforcement, etc.

5. Product Show of Polypropylene Fiber for Reinforcement with 12mm 18mm

- Q:How are geocells used for slope stabilization?

- Geocells are used for slope stabilization by providing a reinforced structure that helps prevent soil erosion and slope failures. They are typically installed on the slope surface and filled with compacted soil or other suitable materials. The interlocking honeycomb-like cells create a stable base, distributing the weight evenly and reducing the pressure on the slope. This helps to retain the soil and prevent it from sliding down. Geocells also allow for vegetation growth within the cells, further enhancing slope stability through root reinforcement. Overall, geocells provide an effective and sustainable solution for slope stabilization.

- Q:How are geotextile bags used in erosion control?

- Geotextile bags are commonly used in erosion control by serving as barriers or structures to prevent the movement of soil or sediment. These bags are typically filled with sand, gravel, or other materials and strategically placed in areas prone to erosion, such as riverbanks or shorelines. The bags effectively absorb and dissipate the energy of flowing water, reducing its erosive force and preventing further soil loss. Additionally, geotextile bags promote vegetation growth by providing a stable base for plants to take root, further strengthening the soil and preventing erosion.

- Q:Are earthwork products available in various colors and finishes?

- Yes, earthwork products are available in various colors and finishes.

- Q:What are the advantages of using geotextile tubes for shoreline protection?

- Geotextile tubes offer several advantages for shoreline protection. Firstly, they provide an effective barrier against erosion by stabilizing the shoreline and preventing sediment displacement. Secondly, they are versatile and can be used in various coastal environments, such as beaches, dunes, and marshlands. Additionally, geotextile tubes are cost-effective compared to traditional methods like rock revetments, as they require less material and labor for installation. Moreover, they are environmentally friendly, as they allow for natural vegetation growth and do not disrupt marine ecosystems. Lastly, geotextile tubes have a longer lifespan and require minimal maintenance, making them a sustainable and reliable solution for shoreline protection.

- Q:What are the challenges in installing and maintaining geosynthetic products in earthwork?

- Some of the challenges in installing and maintaining geosynthetic products in earthwork include: 1. Proper installation: Geosynthetic products require precise installation techniques to ensure their effectiveness. Any errors or deviations during installation can lead to reduced performance or failure of the product. 2. Site conditions: The condition of the site where the geosynthetic products are being installed can pose challenges. Uneven terrain, unstable soils, and adverse weather conditions can make installation difficult and require additional measures to secure the products. 3. Compatibility with other materials: Geosynthetic products must be compatible with the surrounding materials and structures to ensure proper integration and functioning. Compatibility issues can arise due to differences in physical properties, chemical reactions, or long-term durability. 4. Monitoring and maintenance: Once installed, geosynthetic products need regular monitoring and maintenance to ensure their performance over time. This can involve inspection for damage, cleaning, repairs, or replacement of damaged or worn-out sections. 5. Long-term durability: Geosynthetic products are expected to have a long service life, but factors such as exposure to UV radiation, chemical degradation, or mechanical stresses can affect their durability. Regular inspections and maintenance are necessary to address any degradation and ensure the longevity of the products.

- Q:How are earthwork products different from regular construction materials?

- Earthwork products, such as soil, rocks, and gravel, are natural materials that are extracted from the earth's surface and used in construction projects. In contrast, regular construction materials, like bricks, concrete, and steel, are manufactured or processed materials that are specifically designed for construction purposes. The key difference lies in the origin and composition of these materials, as well as their production methods. Earthwork products are generally more cost-effective, readily available, and environmentally friendly, while regular construction materials offer greater structural strength and specific properties tailored to meet construction requirements.

- Q:Can earthwork products be used in sound barriers along highways?

- Yes, earthwork products such as soil, rocks, and other natural materials can be used in sound barriers along highways. These materials can be shaped and arranged to create effective noise barriers that help reduce the impact of highway noise on nearby communities.

- Q:What is the purpose of using geotextile tubes in shoreline stabilization projects?

- The purpose of using geotextile tubes in shoreline stabilization projects is to provide effective erosion control and protect coastal areas from the damaging effects of waves, currents, and storms. These tubes act as a barrier, trapping sediment and preventing it from being washed away, while also promoting the growth of vegetation. They offer a cost-effective and environmentally friendly solution to maintain and restore the natural balance of coastal ecosystems.

- Q:What is the purpose of using geocomposites in pond and lagoon applications?

- The purpose of using geocomposites in pond and lagoon applications is to provide a cost-effective and efficient solution for lining and reinforcing these areas. Geocomposites help in preventing seepage, erosion, and contamination by providing a barrier against water and pollutants. They also help in stabilizing the soil and improving the overall integrity and longevity of the pond or lagoon.

- Q:How are geosynthetic liners used in landfill and pond liner installations?

- Geosynthetic liners are used in landfill and pond liner installations to provide a barrier against leakage and contamination. These liners are made of synthetic materials like HDPE (High-Density Polyethylene) and are placed within the landfill or pond structure to prevent the seepage of pollutants into the surrounding soil and groundwater. They act as a protective barrier, ensuring that any toxic substances or waste materials remain contained within the designated area, thus minimizing environmental risks and protecting nearby ecosystems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polypropylene Fiber for Reinforcement with 12mm 18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords