Polyester Geogrids with High Tensile Strength Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification---Polyester Geogrid

Introduction:

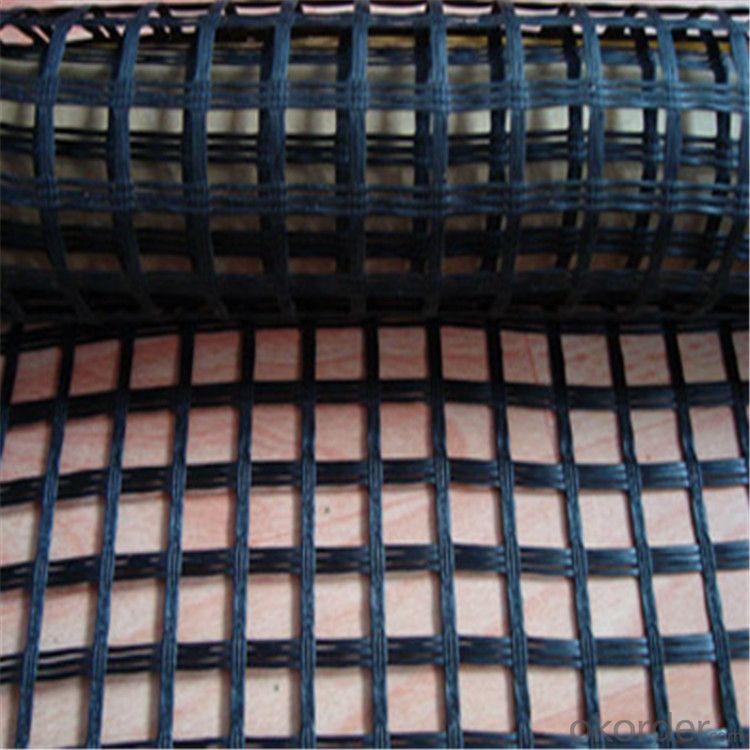

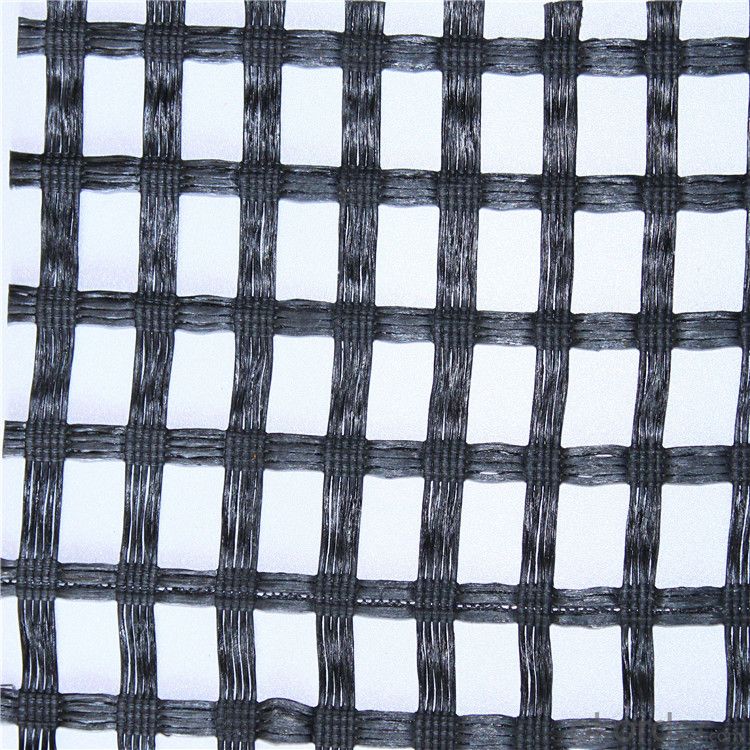

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Features:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Specifications :

Mesh size(mm) | 25.4×25.4 Or 12.5×12.5 | |||||

Breaking strength ≥(KN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 |

Across warp | 30 | 50 | 80 | 100 | 120 | |

Elongation at break ≤(%) | Warp direction | 3 | ||||

Across warp | 3 | |||||

Elasticity modulus(GPA) | 67 | |||||

Thermal tolerance | -100~280℃ | |||||

Width | 1~6m | |||||

Application:

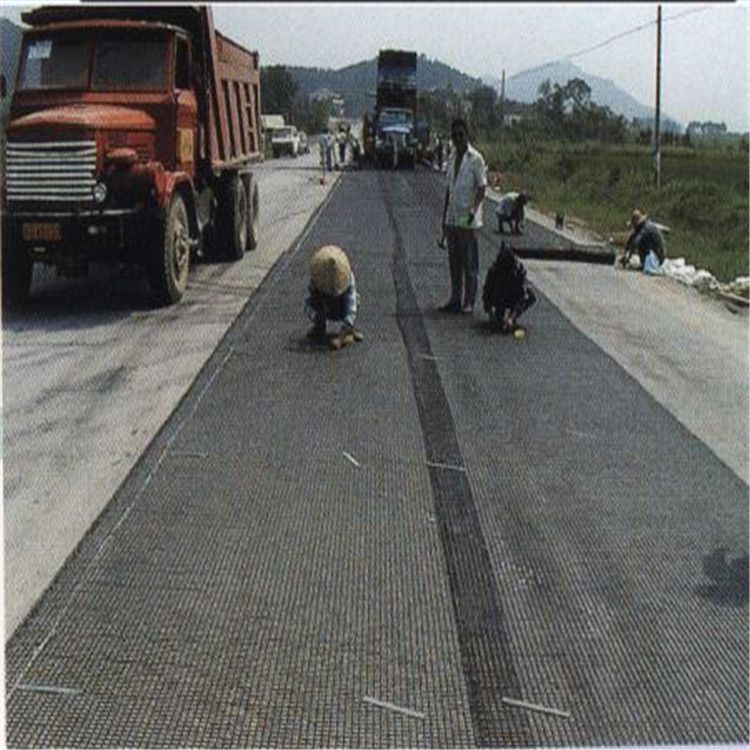

This product is used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, roadbed, and softland loading capacity strengthen.

Function:

This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile

strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after

surface covering own the favorable property of alkali resistance and aging resistance.

It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces).

Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road

crackle.

This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the

roadbed 。

Image of Polyester Geogrid

- Q:What is the meaning of 80 in geogrid TGSG80

- A model can be viewed as a double grid

- Q:What is geogrid, what is the role?

- To enhance the problemGlass fiber geogrid features:The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long service life, can be widely used in the old cement pavement and airport runway maintenance, dams, river, slope protection, bridge pavement engineering field enhancement processing, can give the pavement reinforcement and reinforcement to prevent rutting, fatigue crack of pavement, hot and cold crack and the expansion of reflection crack, and can disperse the bearing capacity of pavement and prolong the service life of the pavement, high tensile strength and low elongation, no long-term creep, high physical and chemical stability, thermal stability, fatigue cracking, rutting resistance, cracking resistance at low temperature delay, reduce reflection crack.

- Q:Are geogrids suitable for use in high groundwater conditions?

- Yes, geogrids are suitable for use in high groundwater conditions. Geogrids are commonly used in civil engineering applications, including in areas with high groundwater levels. They are designed to provide soil stabilization and reinforcement, even in challenging conditions such as high water tables. Geogrids have excellent drainage properties and are resistant to water, making them a reliable solution for projects in high groundwater conditions.

- Q:Can geogrids be used in stabilization of mine tailings ponds?

- Yes, geogrids can be used in the stabilization of mine tailings ponds. Geogrids are commonly used in civil engineering for soil stabilization and reinforcement. They can provide strength and stability to the soil, preventing erosion and minimizing the risk of slope failure. In the context of mine tailings ponds, where the soil is often unstable and prone to erosion, geogrids can be an effective solution for stabilizing the area and preventing environmental hazards.

- Q:Can geogrids be used in reinforced soil slopes for seismic applications?

- Yes, geogrids can be used in reinforced soil slopes for seismic applications. Geogrids provide additional tensile strength to the soil, helping to stabilize the slopes and prevent failure during seismic events. The geogrids act as reinforcement, distributing the forces generated by seismic activity and reducing the potential for slope displacement or collapse.

- Q:What are the design considerations for geogrids in reinforced soil slopes?

- Some important design considerations for geogrids in reinforced soil slopes include the type and strength of the geogrid material, the required tensile strength and stiffness of the geogrid, the appropriate spacing and orientation of the geogrid layers, the connection details and anchorage methods for the geogrids, and the overall stability and safety of the reinforced slope. Other factors to consider include the soil properties, slope geometry, and potential loads or forces acting on the slope. Additionally, proper installation and construction techniques should be considered to ensure the effectiveness and durability of the geogrid reinforcement system.

- Q:What is the effect of temperature on geogrid properties?

- The effect of temperature on geogrid properties can vary depending on the type of geogrid and the specific temperature range. In general, higher temperatures can cause geogrids to expand and become more flexible, potentially increasing their tensile strength and allowing them to better distribute loads. However, extreme temperatures can also lead to thermal degradation and reduced performance. It is important to consider the intended application and temperature conditions when selecting geogrids to ensure optimal performance and longevity.

- Q:Are geogrids suitable for use in bridge abutment reinforcement?

- Yes, geogrids are suitable for use in bridge abutment reinforcement. Geogrids are commonly used in civil engineering projects, including bridges, to enhance the stability and strength of the soil. They provide excellent soil confinement and reinforcement, reducing lateral movement and increasing load-bearing capacity. Geogrids also help distribute loads evenly, minimizing the potential for settlement and improving the overall performance and longevity of bridge abutments.

- Q:Geogrid prices, the price of geogrid, geogrid latest offer

- Biaxially stretched plastic grid, uni directional plastic geogrid.

- Q:Are geogrids resistant to chemical attack?

- Yes, geogrids are generally resistant to chemical attack. They are typically made from high-strength polymers like polyester or polypropylene, which have excellent chemical resistance properties. This allows geogrids to withstand exposure to various chemicals commonly found in soil, water, and other environmental conditions, making them a reliable option for reinforcement and stability in different applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Geogrids with High Tensile Strength Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords