Polyester Geogrid/ Fiberglass Geogrid/ PP Geogrid for Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Geogrid:

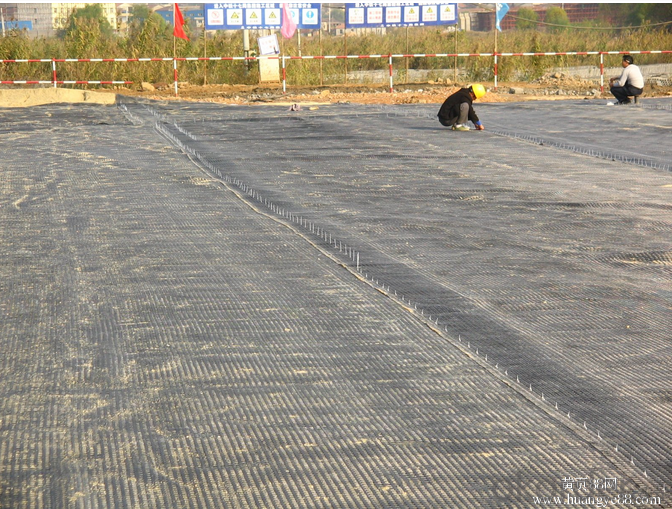

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Introduction of PP/HDPE Uniaxial Geogrid:

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in the longitudinal direction.

Application of PP/HDPE Uniaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

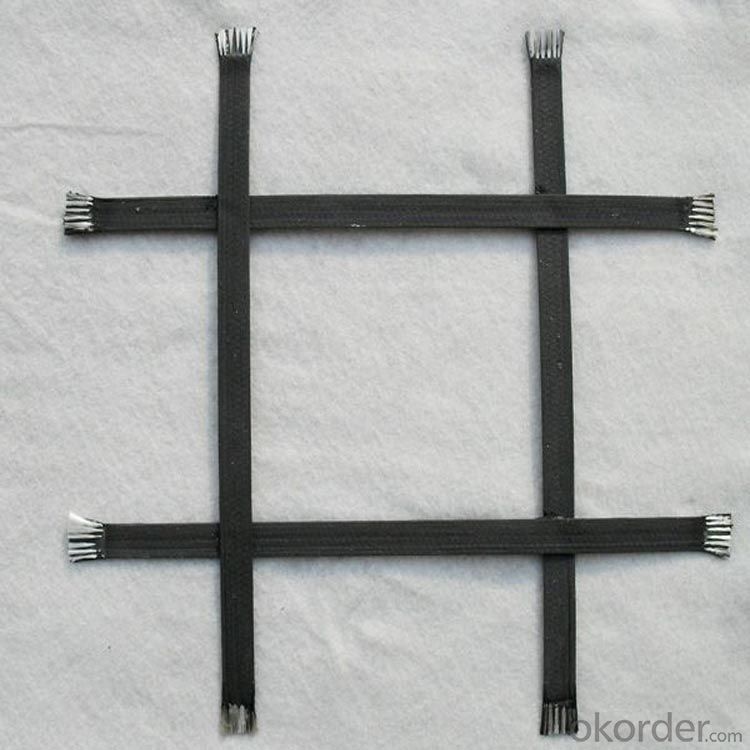

Introduction of Polyester Geogrid:

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

Sarah

- Q:Are earthwork products suitable for constructing boat docks?

- Yes, earthwork products such as soil, clay, or sand, can be suitable for constructing boat docks. These materials can be used to create a stable and solid foundation for the dock structure, providing necessary support and durability. However, it is important to ensure proper engineering and construction techniques are followed to ensure the dock's safety and longevity.

- Q:How do geogrids help in stabilizing soil?

- Geogrids help in stabilizing soil by providing reinforcement and increasing the soil's strength and stability. They are installed within the soil layers, creating a strong interlocking structure that reduces soil movement and prevents erosion. This reinforcement improves the load-bearing capacity of the soil, making it more resistant to settlement and subsidence. Additionally, geogrids distribute the applied loads more evenly, reducing the stress on the soil and preventing the formation of cracks and deformations. Overall, geogrids play a crucial role in enhancing the stability and longevity of soil structures.

- Q:How do erosion control blankets help in slope re-vegetation in earthwork projects?

- Erosion control blankets help in slope re-vegetation in earthwork projects by providing a protective layer over the soil. These blankets are typically made of biodegradable materials, such as straw or coconut fibers, and are placed on the slope to prevent erosion caused by wind, rain, and water flow. They help retain moisture, prevent soil from being washed away, and promote the growth of vegetation by creating an ideal environment for seed germination. Additionally, erosion control blankets also offer protection against weed growth and regulate soil temperature, ultimately aiding in the successful establishment of vegetation on slopes.

- Q:What are the different applications of geotextile bags?

- Geotextile bags have various applications, including erosion control, shoreline protection, sediment filtration, construction site dewatering, flood control, and land reclamation. These bags are also used for slope stabilization, soil reinforcement, and as a barrier for retaining walls. Additionally, geotextile bags can be employed in environmental remediation projects, such as containment of contaminated soil or sludge.

- Q:Are earthwork products suitable for constructing horse arenas?

- Yes, earthwork products such as compacted clay, sand, or crushed stone are commonly used for constructing horse arenas. These materials provide a stable and level surface that is safe for horses to exercise and perform various activities. Additionally, earthwork products can be easily maintained and manipulated to suit the specific needs and preferences of the riders and horses using the arena.

- Q:What are the benefits of using sediment basins?

- Sediment basins offer several benefits, including the prevention of soil erosion and sediment runoff, which can contribute to water pollution. They effectively trap sediment and prevent it from reaching nearby water bodies, preserving water quality and aquatic ecosystems. Sediment basins also help in controlling and managing stormwater runoff, reducing the risk of flooding and soil degradation. Additionally, they provide an opportunity for sediment to settle, allowing for the collection and removal of contaminants before they reach sensitive areas, thus protecting downstream habitats and infrastructure.

- Q:How do earthwork products contribute to sound barrier construction?

- Earthwork products, such as soil and gravel, play a crucial role in sound barrier construction. These products are used to create embankments or berms, which act as natural barriers to absorb and block sound waves. By strategically placing and compacting these materials, earthwork products help in reducing noise pollution and enhancing the effectiveness of sound barriers in mitigating the impact of unwanted sound on surrounding areas.

- Q:Are there any earthwork products specifically designed for pipeline projects?

- Yes, there are earthwork products specifically designed for pipeline projects. These products include pipeline mats, trench shoring systems, and erosion control measures. These specialized products help to ensure the stability and safety of pipelines during construction and maintenance activities.

- Q:How do earthwork products compare to traditional construction materials in terms of cost?

- Earthwork products, such as soil, gravel, and rocks, tend to be more cost-effective compared to traditional construction materials. This is primarily because earthwork materials are often readily available on-site or can be easily sourced locally, reducing transportation costs. Additionally, earthwork products can be recycled or reused, further minimizing expenses. On the other hand, traditional construction materials like concrete, steel, and lumber typically require more resources, energy, and manufacturing processes, making them relatively more expensive. However, it is important to note that the specific cost comparison may vary depending on factors such as project location, scale, and availability of materials.

- Q:How do earthwork products contribute to wastewater treatment systems?

- Earthwork products, such as geotextiles and geosynthetics, play a vital role in wastewater treatment systems. These products are used for filtration, separation, and reinforcement purposes, ensuring the proper functioning and efficiency of these systems. Geotextiles act as a barrier, preventing the clogging of drainage systems by filtering out suspended particles and allowing the water to flow freely. Geosynthetics, on the other hand, provide reinforcement and stability to structures like retaining walls, embankments, and lagoons, increasing the overall durability and longevity of the wastewater treatment system. Therefore, earthwork products are essential in maintaining the effectiveness and sustainability of wastewater treatment systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Geogrid/ Fiberglass Geogrid/ PP Geogrid for Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords